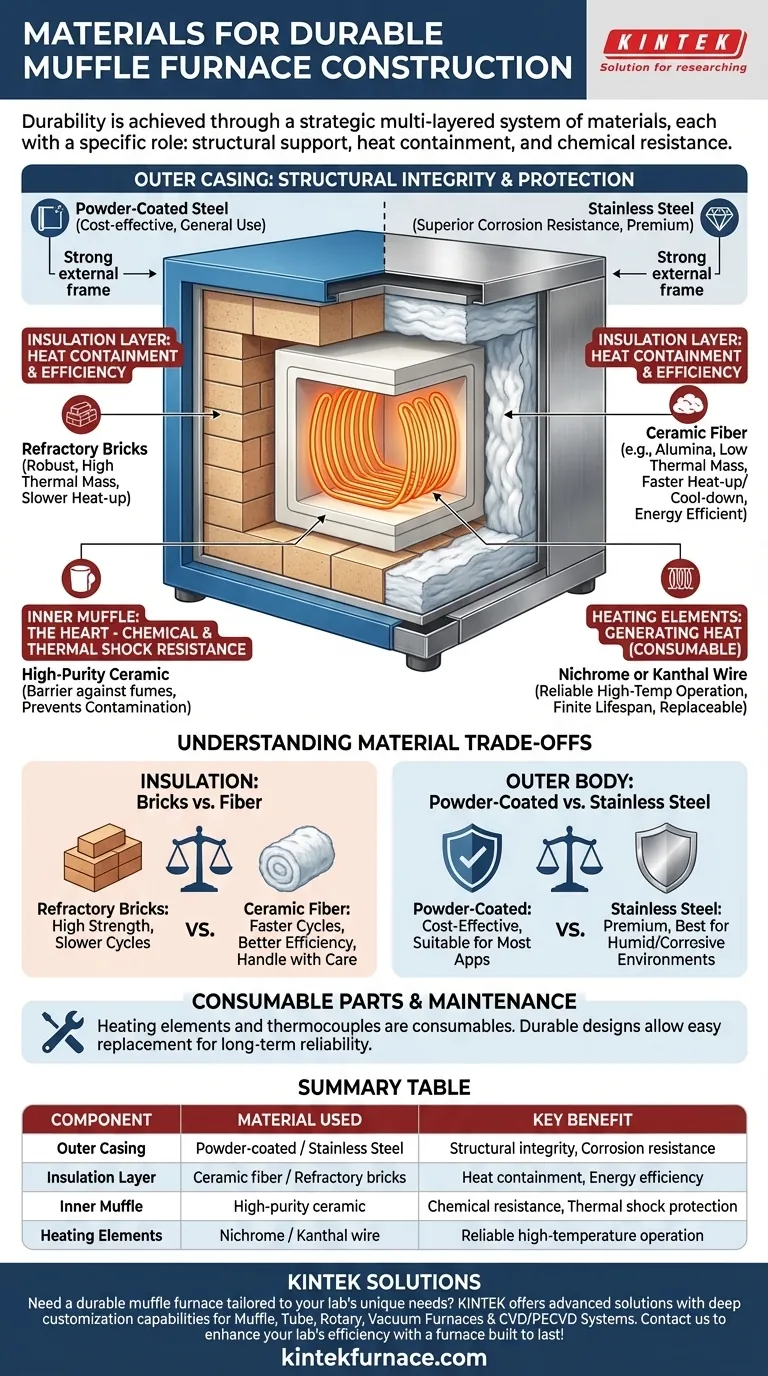

To ensure durability, muffle furnaces are constructed using a multi-layered system of materials. The core components responsible for longevity are a robust outer body, typically made of powder-coated steel or stainless steel, high-performance thermal insulation like ceramic fiber or refractory bricks, and a chemically resistant inner chamber, or muffle, made from high-purity ceramic.

Durability in a muffle furnace is not achieved by a single material, but by a strategic combination of components. Each material is selected for a specific role: providing external structure, containing extreme heat, or resisting chemical attack within the high-temperature chamber.

The Anatomy of a Durable Muffle Furnace

A muffle furnace's design isolates the sample from the direct radiation of the heating elements. Its durability depends entirely on how well each component's material performs its specialized function.

The Outer Casing: Structural Integrity

The external body of the furnace provides structural support and protection for the internal components.

This casing is typically made from Mild Steel (MS) with a powder coating or, for superior longevity, stainless steel. While MS is cost-effective, stainless steel provides enhanced resistance to corrosion, which is vital in lab environments.

The Insulation Layer: Containing Extreme Heat

The most critical factor for both safety and energy efficiency is the quality of the thermal insulation. This layer sits between the outer casing and the inner chamber.

The two most common materials are refractory bricks and ceramic fiber (such as high-purity alumina fiber). This insulation is what keeps the external surface cool to the touch while maintaining extreme temperatures inside, directly contributing to the furnace's operational lifespan and efficiency.

The Inner Muffle: The Heart of the Furnace

The "muffle" itself is the inner chamber that holds the material being heated. It acts as a barrier, protecting the heating elements from any fumes or vapors released by the sample.

This component is almost always made of a durable ceramic material. This provides excellent resistance to thermal shock and attack from the aggressive gases and vapors that can be produced at high temperatures, preventing contamination and degradation.

The Heating Elements: Generating the Heat

While not a structural material, the durability of the heating elements is critical to the furnace's long-term reliability.

These elements, often made of Nichrome or Kanthal wire, are designed to withstand thousands of hours of operation at extreme temperatures. Their ability to resist oxidation is what determines their lifespan and, by extension, the furnace's service intervals.

Understanding the Material Trade-offs

The choice of material for each component involves balancing cost, performance, and the intended application. Understanding these trade-offs is key to selecting the right instrument.

Refractory Bricks vs. Ceramic Fiber

Refractory bricks offer excellent mechanical strength and are very robust. However, they have a high thermal mass, meaning the furnace will heat up and cool down more slowly.

Ceramic fiber insulation has a lower thermal mass, allowing for faster heat-up and cool-down cycles and better energy efficiency. However, it can be more susceptible to mechanical damage if not handled carefully.

Powder-Coated Steel vs. Stainless Steel

A powder-coated steel body is a perfectly suitable and cost-effective choice for most applications.

A stainless steel housing is a premium feature that offers superior protection against rust and corrosion. It is a worthwhile investment if the furnace will be used in a humid environment or with corrosive chemicals.

The Lifespan of Consumables

It's important to recognize that heating elements and temperature sensors (thermocouples) are effectively consumable parts. Their lifespan is finite and is heavily influenced by the maximum operating temperature and the chemical environment inside the furnace. A durable furnace design allows for the easy replacement of these components.

Making the Right Choice for Your Application

The ideal material composition depends entirely on your specific laboratory work.

- If your primary focus is rapid heating and energy efficiency: Choose a furnace with high-quality ceramic fiber insulation.

- If your primary focus is processing heavy loads and maximum physical robustness: A furnace lined with refractory bricks may be a better long-term choice.

- If you work with materials that release corrosive fumes: Prioritize a model with a high-purity ceramic muffle and a stainless steel outer body.

Understanding how these materials work together empowers you to select a furnace that is not just a tool, but a reliable, long-term asset for your work.

Summary Table:

| Component | Material Used | Key Benefit |

|---|---|---|

| Outer Casing | Powder-coated steel or stainless steel | Structural integrity and corrosion resistance |

| Insulation Layer | Ceramic fiber or refractory bricks | Heat containment and energy efficiency |

| Inner Muffle | High-purity ceramic | Chemical resistance and thermal shock protection |

| Heating Elements | Nichrome or Kanthal wire | Reliable high-temperature operation |

Need a durable muffle furnace tailored to your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your experimental requirements. Contact us today to enhance your lab's efficiency and reliability with a furnace built to last!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity