A laboratory muffle furnace is essential because it provides the precise, long-term temperature stability required to control the precipitation kinetics of nickel-based superalloys. By maintaining exact temperatures (commonly 843°C and 700°C) over specific dwell times, these furnaces allow researchers to induce the formation of strengthening phases like gamma prime and eta. This process directly dictates the material's final mechanical properties, specifically its hardness and creep resistance.

The muffle furnace isolates the alloy to maintain a rigid thermal profile and a controlled atmosphere. This precision is the mechanism that allows you to engineer the specific size and morphology of secondary phases, transforming a raw alloy into a high-performance material.

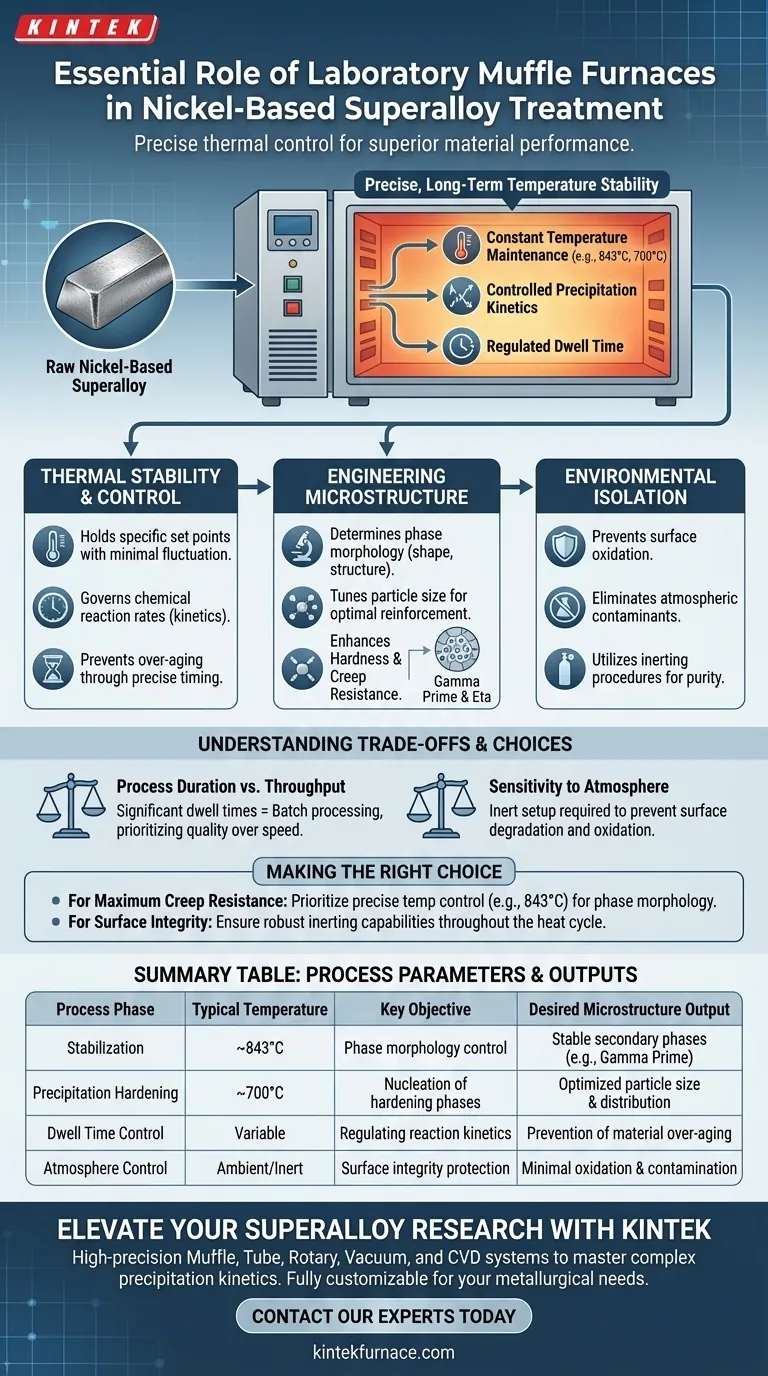

The Critical Role of Thermal Stability

Maintaining Constant Temperature

The stabilization and hardening of superalloys rely on long-term thermal constancy. A muffle furnace is designed to hold specific set points, such as 843°C or 700°C, with minimal fluctuation.

Controlling Precipitation Kinetics

Temperature stability is not merely about heating; it is about controlling the rate of chemical reactions within the solid state. This stability governs the precipitation kinetics of critical phases like gamma prime and eta.

Regulating Dwell Time

The duration the material spends at temperature—the dwell time—is as critical as the temperature itself. The muffle furnace allows for precise timing, ensuring that phase transformations occur to the desired extent without over-aging the material.

Engineering Microstructure and Properties

Determining Phase Morphology

The physical shape and structure of the precipitates (morphology) are sensitive to thermal conditions. By controlling the furnace environment, you determine whether these phases form as discrete particles, needles, or films.

Tuning Particle Size

Mechanical strength is often a function of particle size. The muffle furnace environment allows you to stop the growth of precipitates at the exact size required for optimal reinforcement.

Enhancing Mechanical Performance

The ultimate goal of this thermal manipulation is practical performance. By optimizing the size and distribution of the gamma prime and eta phases, you directly improve the alloy's hardness and creep resistance (the ability to resist deformation under stress at high temperatures).

Environmental Isolation and Integrity

Preventing Surface Oxidation

High-temperature treatment exposes alloys to the risk of oxidation. As noted in supplementary contexts, muffle furnaces can utilize inerting procedures to purge oxygen and water, protecting the component's surface integrity.

Eliminating Contaminants

Furnace inerting also serves a safety and purity function. It removes flammables and unwanted materials from the atmosphere, ensuring that the chemical changes in the alloy are driven solely by heat and not by reaction with atmospheric contaminants.

Understanding the Trade-offs

Process Duration vs. Throughput

Achieving precise phase distribution requires significant dwell times. This necessitates a batch-processing approach that prioritizes material quality over rapid production speed.

Sensitivity to Atmosphere

While muffle furnaces provide excellent thermal stability, standard models may require additional setup for inert atmospheres. Without proper inerting, the benefit of thermal precision can be negated by surface degradation or oxidation.

Making the Right Choice for Your Goal

To achieve the best results with nickel-based superalloys, align your furnace parameters with your specific mechanical requirements:

- If your primary focus is Maximum Creep Resistance: Prioritize precise temperature control at the stabilization set point (e.g., 843°C) to optimize the morphology of the grain boundary phases.

- If your primary focus is Surface Integrity: Ensure your furnace setup includes robust inerting capabilities to purge oxygen and water throughout the entire heat cycle.

The muffle furnace is not just a heating element; it is a precision instrument for dictating the microstructural evolution that defines a superalloy's performance.

Summary Table:

| Process Phase | Typical Temperature | Key Objective | Desired Microstructure Output |

|---|---|---|---|

| Stabilization | ~843°C | Phase morphology control | Stable secondary phases (e.g., Gamma Prime) |

| Precipitation Hardening | ~700°C | Nucleation of hardening phases | Optimized particle size and distribution |

| Dwell Time Control | Variable | Regulating reaction kinetics | Prevention of material over-aging |

| Atmosphere Control | Ambient/Inert | Surface integrity protection | Minimal oxidation and contamination |

Elevate Your Superalloy Research with KINTEK

Precise thermal profiles are the difference between material failure and high-performance excellence. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to master the complex precipitation kinetics of nickel-based superalloys. Whether you need to optimize creep resistance or ensure surface integrity, our lab high-temperature furnaces are fully customizable to meet your unique metallurgical needs.

Ready to transform your raw alloys into high-performance materials? Contact our technical experts today to find your perfect thermal solution!

Visual Guide

References

- Guilherme Maziero Volpato, Márcio C. Fredel. Influence of a Standard Heat Treatment on the Microstructure and Properties of Inconel X‐750 Produced by Laser Powder Bed Fusion. DOI: 10.1002/adem.202500306

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a laboratory box resistance furnace or muffle furnace necessary for the synthesis of the MgCo2O4 spinel structure?

- What industries commonly use industrial muffle furnaces? Unlock Precision Heating for Diverse Sectors

- Which industries benefit from the use of muffle furnaces? Essential Applications Across 8 Key Sectors

- How is a muffle furnace utilized in the two-stage calcination for C3N4 nanosheets? Precision Thermal Synthesis Guide

- What is the proper procedure after completing an experiment with the muffle furnace? Ensure Safety and Accuracy in Your Lab

- Why is a precision-controlled muffle furnace necessary for RuO2/g-C3N4 heat treatment? Ensure Perfect Catalysts

- What precautions should be taken when melting samples with alkaline substances? Safeguard Your Furnace from Corrosion

- Why is a box muffle furnace required for In2O3 nanofibers? Expert Synthesis & Pre-Oxidation Guide