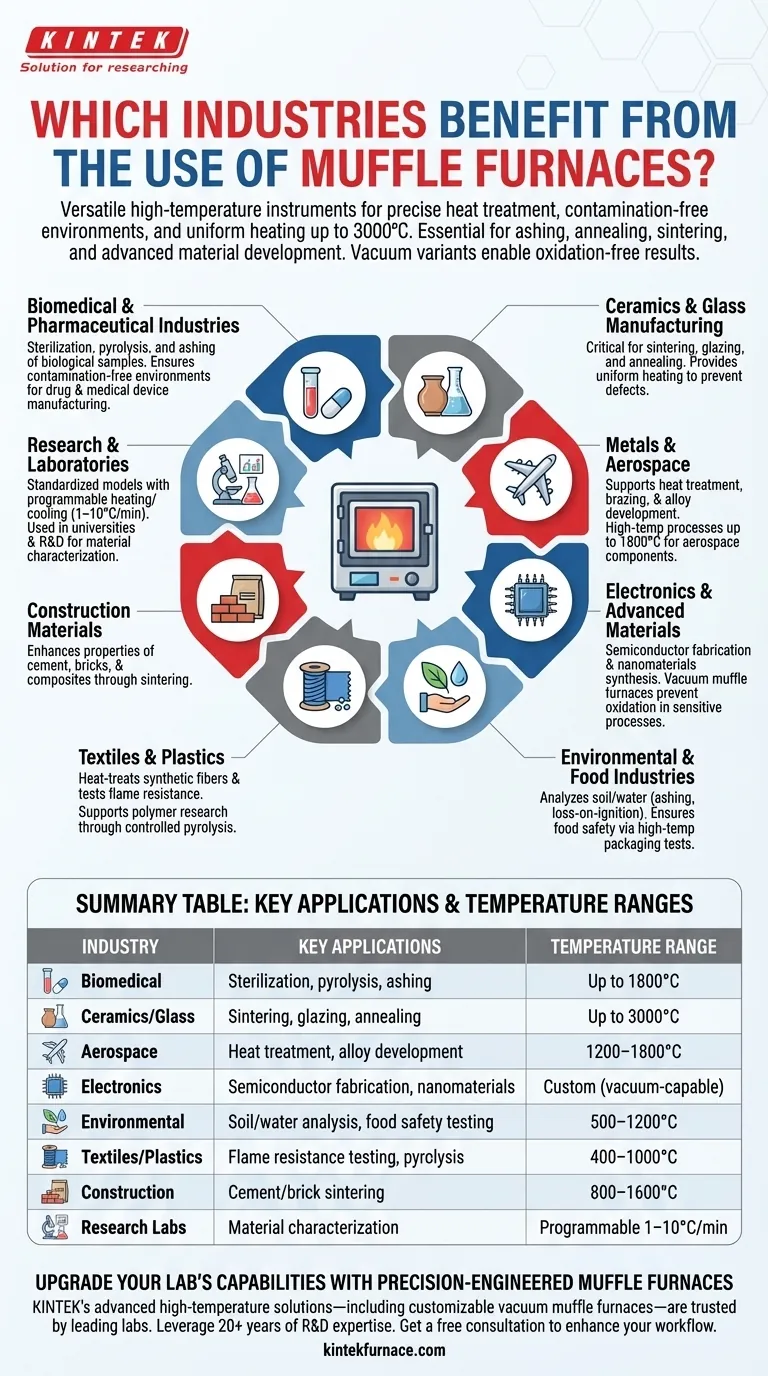

Muffle furnaces are versatile high-temperature instruments used across numerous industries for processes requiring precise heat treatment, contamination-free environments, and uniform temperature distribution. Key sectors benefiting from these furnaces include biomedical, ceramics, glass, pharmaceuticals, plastics, textiles, aerospace, automotive, electronics, healthcare, construction, food, environmental analysis, and materials science. Their ability to reach temperatures up to 3000°C makes them indispensable for applications like ashing, annealing, sintering, and advanced material development. The vacuum muffle furnace variant further enhances their utility by enabling oxidation-free results in high-purity processes.

Key Points Explained:

-

Biomedical & Pharmaceutical Industries

- Used for sterilization, pyrolysis, and ashing of biological samples.

- Ensures contamination-free environments for drug formulation and medical device manufacturing.

-

Ceramics & Glass Manufacturing

- Critical for sintering, glazing, and annealing processes.

- Provides uniform heating to prevent defects in final products.

-

Metals & Aerospace

- Supports heat treatment, brazing, and alloy development.

- Industrial models (e.g., Thermolyne) enable high-temperature processes up to 1800°C for aerospace components.

-

Electronics & Advanced Materials

- Used in semiconductor fabrication and nanomaterials synthesis.

- Vacuum muffle furnaces prevent oxidation during sensitive processes like thin-film deposition.

-

Environmental & Food Industries

- Analyzes soil/water samples via ashing and loss-on-ignition tests.

- Ensures food safety by testing packaging materials at high temperatures.

-

Textiles & Plastics

- Heat-treats synthetic fibers and tests flame resistance.

- Supports polymer research through controlled pyrolysis.

-

Construction Materials

- Enhances properties of cement, bricks, and composites through sintering.

-

Research & Laboratories

- Standardized models offer programmable heating/cooling rates (1–10°C/min) for reproducible experiments.

- Used in universities and R&D centers for material characterization.

These industries leverage muffle furnaces for their precision, reliability, and ability to meet stringent process requirements—technologies that quietly shape modern manufacturing and scientific advancement.

Summary Table:

| Industry | Key Applications | Temperature Range |

|---|---|---|

| Biomedical | Sterilization, pyrolysis, ashing | Up to 1800°C |

| Ceramics/Glass | Sintering, glazing, annealing | Up to 3000°C |

| Aerospace | Heat treatment, alloy development | 1200–1800°C |

| Electronics | Semiconductor fabrication, nanomaterials | Custom (vacuum-capable) |

| Environmental | Soil/water analysis, food safety testing | 500–1200°C |

| Textiles/Plastics | Flame resistance testing, pyrolysis | 400–1000°C |

| Construction | Cement/brick sintering | 800–1600°C |

| Research Labs | Material characterization | Programmable 1–10°C/min |

Upgrade your lab’s capabilities with precision-engineered muffle furnaces

KINTEK’s advanced high-temperature solutions—including customizable vacuum muffle furnaces—are trusted by leading biomedical, aerospace, and materials science labs worldwide. Leverage our 20+ years of R&D expertise and in-house manufacturing to design a furnace tailored to your exact process requirements.

Get a free consultation to explore how our systems can enhance your workflow.

Products You Might Be Looking For:

High-purity vacuum observation windows for process monitoring

Precision vacuum feedthroughs for sensitive electronic applications

Lab-grade MPCVD systems for advanced material synthesis

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites