The proper procedure after completing a muffle furnace experiment involves a sequence of turning off the power, allowing for a controlled initial cooling period, and then safely removing the hot sample. Once the heating cycle is complete, you must switch off the furnace's main power. Before retrieving your sample, it is critical to let the furnace cool slightly with the door closed or minimally cracked to prevent severe burns and avoid thermal shock to the furnace lining.

The shutdown process is a deliberate balance between three critical factors: ensuring operator safety from extreme heat, preserving the integrity of your sample by preventing moisture absorption, and protecting the furnace itself from damage caused by rapid temperature changes.

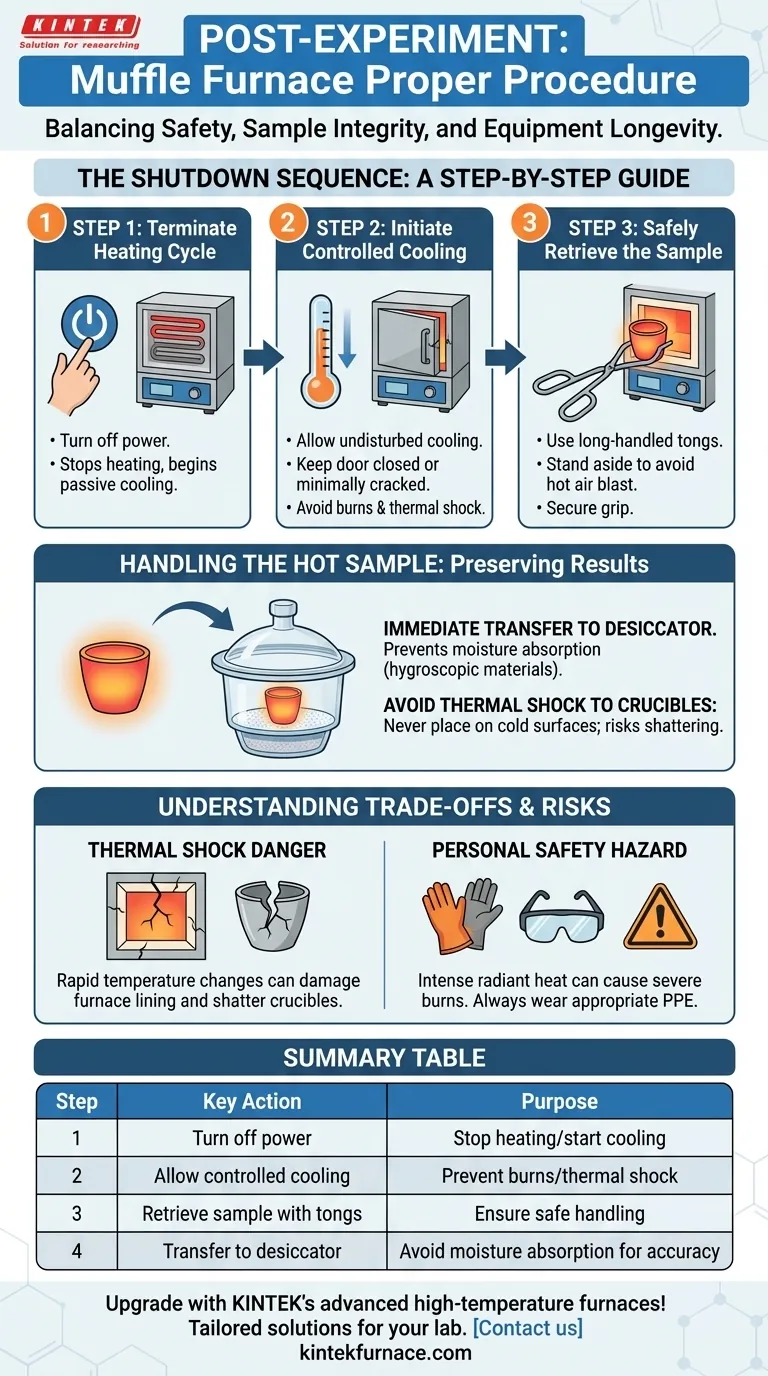

The Shutdown Sequence: A Step-by-Step Guide

Following a precise sequence is not just about safety; it is fundamental to achieving reliable experimental results and maintaining the longevity of the equipment.

Step 1: Terminate the Heating Cycle

The first and most straightforward step is to turn off the power to the furnace. This immediately stops the heating elements, allowing the furnace to begin its cooling phase passively.

Step 2: Initiate Controlled Cooling

Do not immediately fling the furnace door open. The internal temperature can still be exceptionally high, posing a significant burn risk from radiant heat.

Allow the furnace to cool undisturbed for a period. Some procedures call for slightly cracking the door open to accelerate cooling, but this must be done with extreme caution.

Step 3: Safely Retrieve the Sample

Once the initial, intense heat has subsided, you can retrieve your sample. Always use long-handled tongs or forceps designed for high-temperature work.

Open the furnace door carefully and stand to the side to avoid a blast of hot air. Securely grip the crucible or sample container and remove it from the chamber in a smooth, steady motion.

Handling the Hot Sample: Preserving Your Results

Removing the sample from the furnace is only half the task. Proper handling in the moments that follow is critical to the accuracy of your work.

The Critical Role of the Desiccator

Immediately transfer the hot crucible to a desiccator. This is a sealed container with a desiccant (a moisture-absorbing substance) at the bottom.

Many materials, especially after ashing, are highly hygroscopic, meaning they readily absorb moisture from the air. Allowing a hot sample to cool in open air will cause its measured weight to be artificially high, compromising your results.

Avoiding Thermal Shock to Crucibles

Never place a hot crucible directly onto a cold lab bench or surface. The drastic temperature difference can cause the ceramic or porcelain to shatter, resulting in a complete loss of your sample.

Understanding the Trade-offs and Risks

Every step in the shutdown procedure is designed to mitigate a specific risk. Understanding these risks helps you make informed decisions.

The Danger of Thermal Shock

A muffle furnace's heating chamber is made of refractory materials that are sensitive to rapid temperature changes. Opening the door too wide while the furnace is at peak temperature can introduce a rush of cool air, creating thermal shock that may lead to cracks in the furnace lining over time.

Personal Safety: The Unseen Hazard

The most immediate risk is severe burns. The heat radiating from an open furnace door is intense and can cause injury even without direct contact. Always wear appropriate personal protective equipment (PPE), including heat-resistant gloves and safety glasses.

The Problem of Cooling Speed vs. Sample Integrity

You face a direct trade-off between speed and accuracy. While you want to retrieve your sample quickly to place it in a desiccator, you must wait long enough for the initial heat to dissipate for safe handling. This makes the immediate transfer to the desiccator once removed a non-negotiable step for accurate results.

Finalizing Your Experiment with Confidence

By understanding the principles behind the procedure, you can ensure every experiment concludes safely and successfully.

- If your primary focus is operator safety: Always prioritize a longer cooling time before opening the door and use long-handled tools.

- If your primary focus is sample accuracy: Your most critical action is the immediate transfer of the hot crucible into a desiccator to prevent moisture absorption.

- If your primary focus is equipment longevity: Avoid aggressive cooling by opening the door too wide or too soon, as this prevents thermal shock to the furnace lining.

Following this disciplined procedure protects you, your equipment, and the integrity of your scientific data.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Turn off power | Stop heating and start cooling phase |

| 2 | Allow controlled cooling | Prevent burns and thermal shock |

| 3 | Retrieve sample with tongs | Ensure safe handling |

| 4 | Transfer to desiccator | Avoid moisture absorption for accuracy |

Upgrade your lab's efficiency and safety with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs, enhancing reliability and performance. Contact us today to discuss how we can support your research goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity