To clean a muffle furnace, you must first ensure it is completely cool and disconnected from power. The standard procedure involves using a soft brush to loosen any debris, ash, or oxides from the chamber, then removing the particles with a vacuum cleaner. For any remaining surface residue, you can wipe the interior with a slightly damp cloth, taking care not to oversaturate the insulating material.

Cleaning a muffle furnace is not merely about housekeeping. It is a critical maintenance task that protects the furnace's refractory lining from corrosion, prevents cross-contamination between samples, and ensures the continued accuracy and safety of your operations.

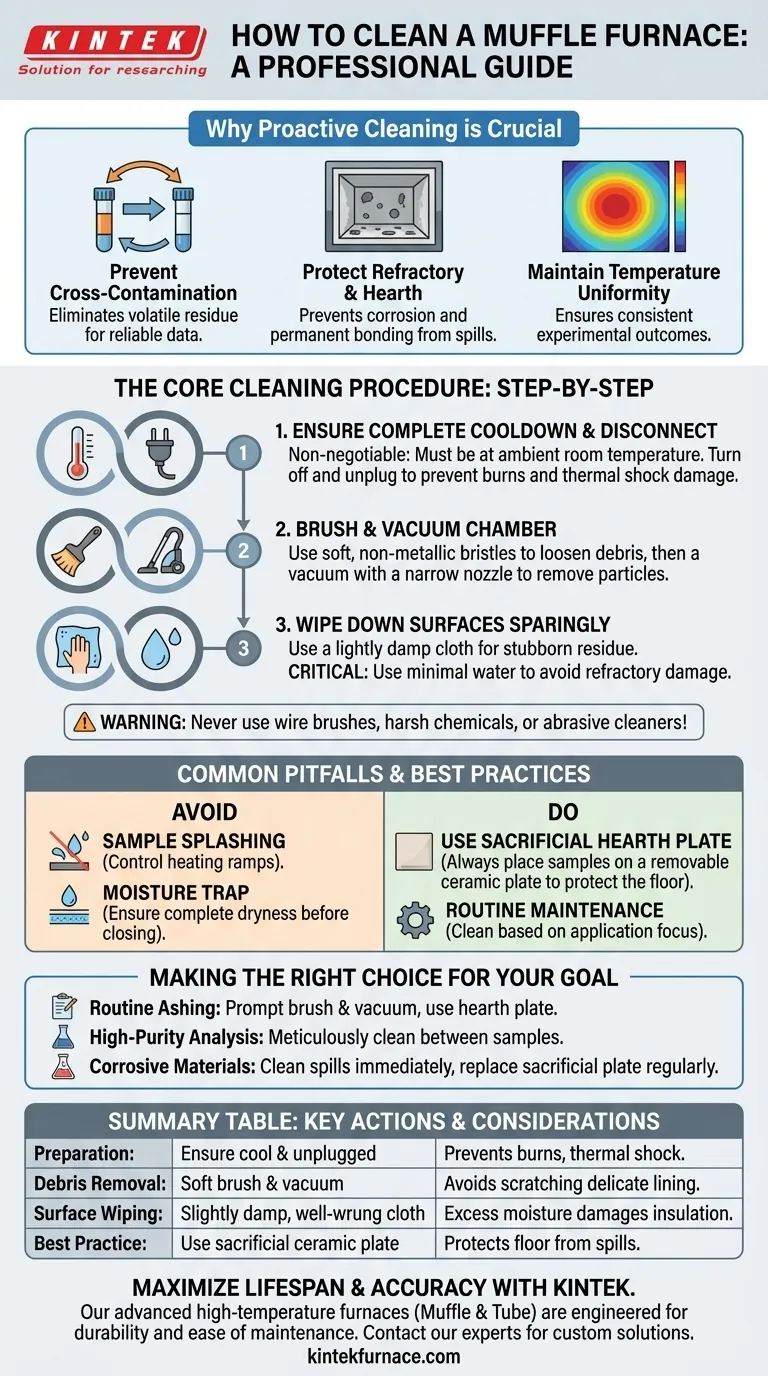

The Core Cleaning Procedure: A Step-by-Step Guide

Proper cleaning can only begin once the furnace is in a safe, cool state. Rushing this process can lead to personal injury or damage to the furnace itself.

Step 1: Ensure Complete Cooldown and Power Disconnect

Before any cleaning, the furnace must be at ambient room temperature. This is non-negotiable.

Attempting to clean a hot furnace poses a severe burn risk. Furthermore, introducing a cool object or cloth into a hot chamber can cause thermal shock, potentially cracking the delicate refractory insulation or heating elements. Always turn off and unplug the unit.

Step 2: Brush and Vacuum the Chamber

The primary goal is to remove loose particulate matter without damaging the furnace interior.

Use a brush with soft, non-metallic bristles to gently sweep down the walls and floor of the chamber. Once the debris is loosened, use a vacuum cleaner with a narrow nozzle attachment to carefully remove all particles.

Step 3: Wipe Down Surfaces Sparingly

For stubborn dust or non-corrosive stains, a damp cloth can be used.

Lightly moisten a clean, soft cloth with water and wring it out thoroughly. Gently wipe the interior surfaces. It is critical to use minimal water, as excessive moisture can be absorbed by the porous refractory material and cause damage during the next heating cycle. The exterior can be wiped down similarly.

Why Proactive Cleaning is Crucial for Performance

Understanding the "why" behind the cleaning protocol helps build a consistent maintenance habit. It directly impacts the quality of your results and the lifespan of the equipment.

Preventing Sample Cross-Contamination

Residue from a previous experiment, even in microscopic amounts, can become volatile at high temperatures and contaminate a new sample. For trace analysis or high-purity applications, a clean chamber is essential for reliable data.

Protecting the Refractory Lining and Hearth

Many samples, when heated, can produce slag, oxides, or other byproducts. If these materials splash or spill, they can chemically react with the furnace's hearth and insulation, causing corrosion, pitting, and permanent bonding. This damage degrades performance and can lead to expensive repairs.

Maintaining Temperature Uniformity

A thick layer of ash or debris can act as an insulator, creating cold spots within the chamber. This disrupts the uniform heating environment that is vital for consistent and repeatable experimental outcomes.

Common Pitfalls and Best Practices

Avoiding common mistakes is as important as the cleaning process itself. The best approach to cleaning is to minimize the need for it through proper operational habits.

The Hazard of Sample Splashing

The most common cause of furnace damage is sample material splashing onto the hearth. This is often due to heating a sample too quickly or to an excessive temperature. Always follow a controlled heating ramp rate to prevent this.

Use a Sacrificial Hearth Plate

To protect the furnace floor, always place samples on a removable ceramic hearth plate or alumina shelf. This plate catches any spills and can be easily removed for cleaning or replacement. This practice is the modern, safe alternative to older advice suggesting asbestos boards and is the single best way to preserve the furnace's primary insulation.

Avoid Abrasive or Chemical Cleaners

Never use wire brushes, scrapers, or harsh chemical cleaning agents inside the furnace. These will scratch, erode, and permanently damage the soft refractory lining and potentially the heating elements.

The Risk of Moisture

After wiping with a damp cloth, ensure the furnace is completely dry before closing the door for storage. It is often best to leave the door ajar for several hours. Trapped moisture can degrade the insulation over time and lead to a surge of steam upon the next startup.

Making the Right Choice for Your Goal

Your specific application should guide your maintenance frequency and focus.

- If your primary focus is routine ashing or heat treatment: Promptly brush and vacuum out any residue after each use and always use a protective hearth plate.

- If your primary focus is high-purity analysis or trace element work: Meticulously clean the chamber between different sample types to eliminate any risk of cross-contamination.

- If you are working with potentially corrosive materials: Immediately clean any visible spills and consider the hearth plate a consumable, sacrificial component to be replaced regularly.

Proper maintenance is not an afterthought; it is the key to ensuring your muffle furnace remains a reliable and precise instrument for years to come.

Summary Table:

| Cleaning Step | Key Action | Critical Consideration |

|---|---|---|

| Preparation | Ensure furnace is cool and unplugged. | Prevents burns and thermal shock damage. |

| Debris Removal | Use a soft brush and vacuum. | Avoids scratching the delicate refractory lining. |

| Surface Wiping | Use a slightly damp, well-wrung cloth. | Excess moisture can damage insulation upon heating. |

| Best Practice | Always use a sacrificial ceramic hearth plate. | Protects the furnace floor from spills and splashes. |

Maximize the lifespan and accuracy of your laboratory heating processes. Proper maintenance starts with the right equipment. KINTEK's advanced high-temperature furnaces, including our Muffle and Tube Furnaces, are engineered for durability and ease of maintenance. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with robust solutions complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact our experts today to find the perfect furnace for your application and ensure years of reliable performance.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control