At its core, a modern box furnace's temperature control console is much more than a simple thermostat. It integrates sophisticated automation features designed to deliver precise and repeatable thermal processing. The two most critical features are self-tuning PID instrumentation, which automatically optimizes temperature stability, and a ramp-to-setpoint function that allows for fully programmable heating and cooling rates.

The central purpose of these features is to shift the burden of complex process control from the operator to the machine. By automating temperature stability and heat-up profiles, the console ensures consistent, reliable, and repeatable results for any thermal process.

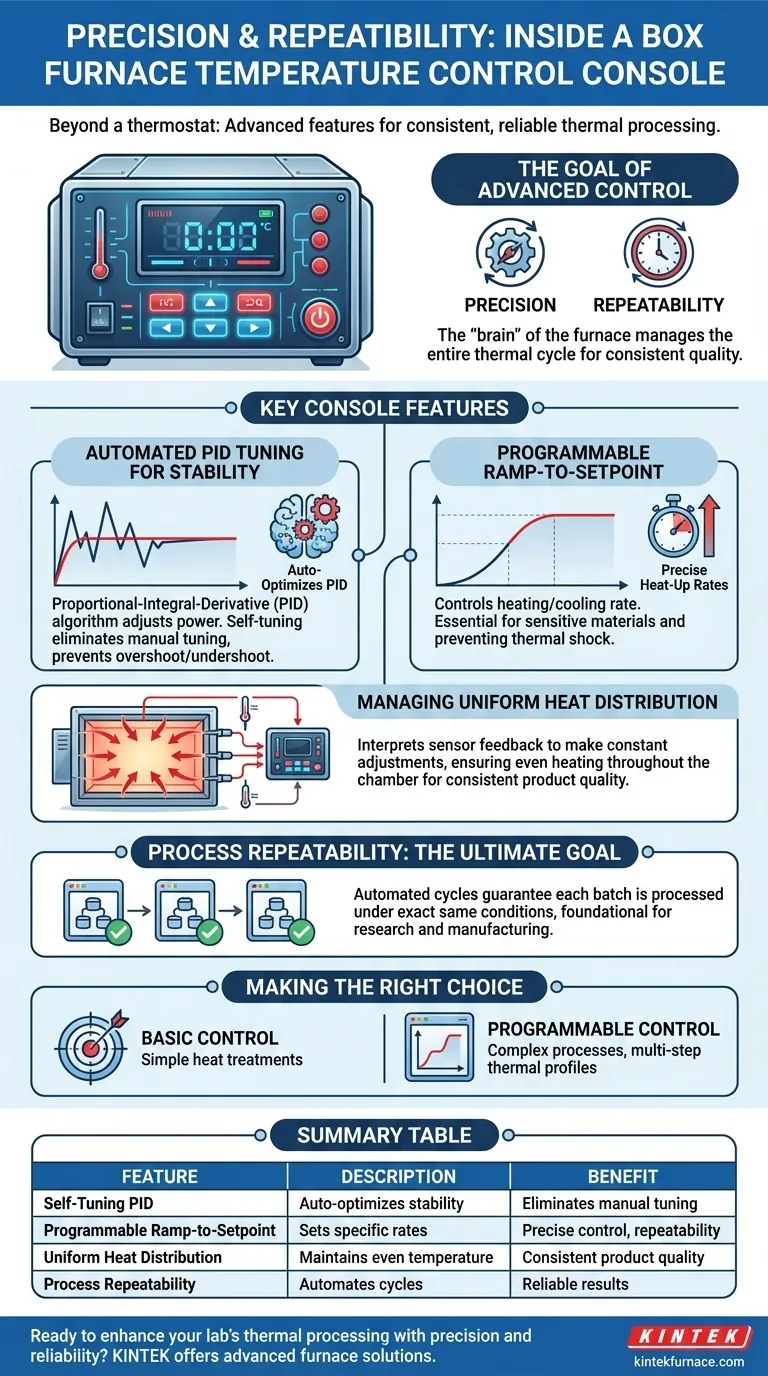

The Goal of Advanced Control: Precision and Repeatability

A temperature control console is the brain of the furnace. Its primary job is not just to reach a temperature, but to manage the entire thermal cycle with precision. This is achieved through several key functions.

Automated PID Tuning for Stability

A Proportional-Integral-Derivative (PID) controller is the algorithm that continuously adjusts the furnace's power to maintain a stable temperature.

Self-tuning instrumentation automatically calculates the optimal PID settings for your specific process. This eliminates the need for manual tuning, which can be complex and time-consuming, and ensures the furnace avoids overshooting or undershooting the target temperature.

Programmable Ramp-to-Setpoint

Many thermal processes require not just a specific final temperature, but a specific rate of heating or cooling.

The ramp-to-setpoint feature allows you to program this rate. This gives you precise control over the entire heat-up curve, which is critical for processing sensitive materials or ensuring process repeatability.

Managing Uniform Heat Distribution

The console works in tandem with the furnace's physical components, such as its insulated heating zones and temperature sensors.

By interpreting sensor feedback, the computer-controlled system makes constant adjustments to maintain uniform heat distribution throughout the chamber. This ensures that a dense load is heated evenly, leading to consistent product quality.

Ensuring Process Repeatability

The ultimate goal of these features is process repeatability. By automating tuning and programming the heat-up cycle, the console guarantees that each batch is processed under the exact same thermal conditions.

This reliability is foundational for applications in research, manufacturing, and quality control where results must be consistent and dependable.

Implications and Considerations

Advanced control features directly impact a furnace's performance and suitability for different tasks. Understanding their implications is key to selecting the right equipment.

The Role of High-Quality Components

The most sophisticated control console is only as effective as the hardware it commands. Highly reliable designs use premium components, from the temperature sensors to the heating elements.

This synergy between smart controls and robust hardware is what enables rapid heat-up, quick response times, and a long operational lifespan.

Basic vs. Programmable Control

A basic controller may only allow you to set a single target temperature. This is sufficient for simple heat treatments.

However, a fully programmable controller with ramp-and-soak capabilities allows for multi-step thermal profiles. This is essential for more complex processes that involve holding at different temperatures for specific durations.

The Impact on External Temperatures

The control system also contributes to safety and efficiency. By precisely managing power output, it works with the furnace's internal construction and outer shell design to help reduce external surface temperatures, creating a safer and more comfortable working environment.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its control capabilities to your specific application.

- If your primary focus is simple, consistent heat-treating: A system with reliable, self-tuning PID control is essential for ensuring temperature stability.

- If your primary focus is processing thermally sensitive materials: The programmable ramp-to-setpoint feature is non-negotiable for preventing thermal shock and ensuring process integrity.

- If your primary focus is high-volume production or quality control: You need a fully programmable controller that ensures absolute process repeatability batch after batch.

Ultimately, choosing a furnace with the right control console empowers you to execute your thermal processes with confidence, precision, and reliability.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Self-Tuning PID | Automatically optimizes temperature stability | Eliminates manual tuning, prevents overshooting/undershooting |

| Programmable Ramp-to-Setpoint | Allows setting specific heating/cooling rates | Enables precise control for sensitive materials and repeatability |

| Uniform Heat Distribution | Maintains even temperature across the chamber | Ensures consistent product quality |

| Process Repeatability | Automates thermal cycles for identical batch conditions | Guarantees reliable results in research and manufacturing |

Ready to enhance your lab's thermal processing with precision and reliability? KINTEK offers advanced high-temperature furnace solutions, including Box Furnaces with state-of-the-art temperature control consoles. Leveraging our exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can optimize your processes and deliver consistent, repeatable results!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits