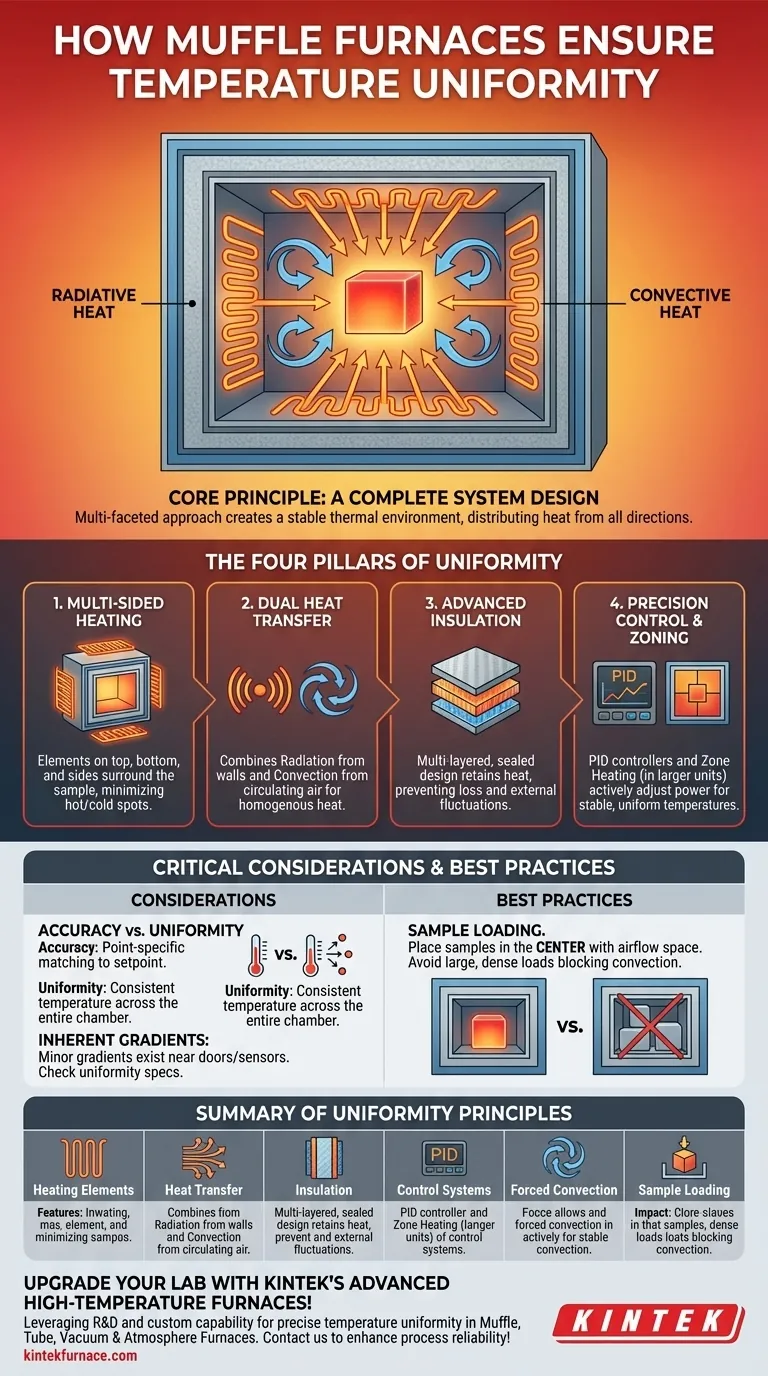

In short, muffle furnaces ensure temperature uniformity through a multi-faceted design approach. This includes the strategic placement of heating elements on multiple sides of the chamber, the combined use of radiative and convective heat transfer, and precision digital controllers that constantly regulate power output to maintain a stable thermal environment.

The core principle is not a single feature, but a complete system design. A well-engineered muffle furnace creates a highly insulated, stable thermal environment where heat is generated from all directions and distributed evenly, ensuring the entire sample experiences the same processing temperature.

The Core Principles of Uniform Heating

To understand how uniformity is achieved, we must look at the furnace's fundamental design. It's a system where heat generation, transfer, and retention all work in concert.

Strategic Placement of Heating Elements

The most critical factor is avoiding a single heat source. High-quality furnaces distribute heating elements on multiple sides of the internal chamber—often at the top, bottom, and sides.

This multi-directional heating ensures that the sample isn't just being heated from one direction. It creates an encompassing field of energy, minimizing hot and cold spots that would otherwise form.

The Dual Role of Radiation and Convection

Muffle furnaces leverage two types of heat transfer simultaneously.

First, the heating elements heat the muffle (the inner chamber walls), which then radiates thermal energy inward onto the sample from all surfaces. Second, the air or inert gas inside the chamber heats up and circulates, transferring heat via convection. This combination is far more effective at achieving a homogenous temperature than relying on either method alone.

High-Quality Insulation and Chamber Design

The furnace's ability to retain heat is just as important as its ability to generate it. Modern furnaces use advanced, multi-layered insulation to prevent heat from escaping.

This creates a stable thermal environment where the temperature can equalize across the entire chamber volume. The enclosed, sealed design also prevents drafts or external factors from introducing temperature fluctuations.

Advanced Control for Precision and Stability

Beyond the physical construction, modern electronics provide the fine-tuning required for true uniformity.

The Role of Programmable Controllers

Modern digital controllers do more than just turn the heat on and off. They use sophisticated algorithms (like PID loops) to continuously monitor the chamber temperature via a thermocouple and make micro-adjustments to the power sent to the heating elements.

This prevents temperature overshoot and undershoot, holding the setpoint with remarkable stability, which is the foundation for a uniform environment.

Zone Heating in Larger Furnaces

In larger industrial furnaces, natural temperature gradients can form, with areas near the door often being slightly cooler. To combat this, some models employ zone heating.

The furnace chamber is divided into multiple "zones," each with its own thermocouple and independent power control. The controller can then direct more energy to cooler zones as needed, actively forcing the entire volume to a uniform temperature.

Forced Convection and Atmosphere Control

For the highest levels of uniformity, some furnaces—often called atmosphere furnaces—incorporate a gas circulation system.

These systems use a fan or controlled gas inlet/outlet ports to actively circulate the atmosphere within the chamber. This forced convection physically mixes the air or gas, eliminating stagnant layers and ensuring the temperature is consistent even in hard-to-reach corners.

Understanding the Trade-offs and Limitations

No system is perfect, and understanding the limitations is key to achieving reliable results.

Inherent Temperature Gradients

Even in the best furnaces, perfect uniformity is a theoretical ideal. Minor temperature gradients will always exist, especially near the door opening, thermocouple sensor, and vents. Manufacturers often provide a uniformity specification (e.g., ±5°C) for a specific volume within the chamber.

Control Accuracy vs. Temperature Uniformity

It is critical to distinguish between control accuracy and temperature uniformity. Accuracy (e.g., ±1°C) refers to how closely the temperature at the single thermocouple point matches the setpoint. Uniformity describes how much the temperature varies across different points within the entire chamber. A furnace can be highly accurate at one point but have poor uniformity.

The Impact of Sample Loading

How you load your sample significantly impacts uniformity. A very large or dense sample can create a local cold spot and obstruct the natural flow of convective heat. For best results, place samples in the center of the chamber and allow for airflow around them.

Making the Right Choice for Your Goal

Selecting the right equipment depends entirely on the precision your process demands.

- If your primary focus is general ashing or simple heat-treating: A standard box furnace with heating elements on at least three sides and a reliable digital controller is sufficient.

- If your primary focus is sensitive material science or process validation: Seek out a furnace with a published temperature uniformity specification and consider models with zone heating or forced gas circulation.

- If your primary focus is processing large or dense workloads: Prioritize a furnace with zone heating and pay close attention to loading guidelines to ensure heat can reach all parts of the sample.

By understanding these design principles, you can confidently select the right tool and implement a process that yields consistent, reliable, and repeatable results.

Summary Table:

| Principle | Key Features | Impact on Uniformity |

|---|---|---|

| Heating Element Placement | Elements on top, bottom, and sides | Reduces hot/cold spots by surrounding the sample with heat |

| Heat Transfer Methods | Combines radiation and convection | Ensures even heat distribution from all directions |

| Insulation and Chamber Design | Multi-layered insulation, sealed chamber | Maintains stable thermal environment and prevents heat loss |

| Control Systems | PID controllers, zone heating | Prevents temperature fluctuations and adjusts for gradients |

| Forced Convection | Gas circulation fans in atmosphere furnaces | Eliminates stagnant areas for high uniformity |

| Sample Loading | Proper placement and airflow considerations | Avoids cold spots and ensures consistent heating |

Upgrade your lab with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise temperature uniformity to meet your unique experimental needs. Contact us today to enhance your process reliability and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals