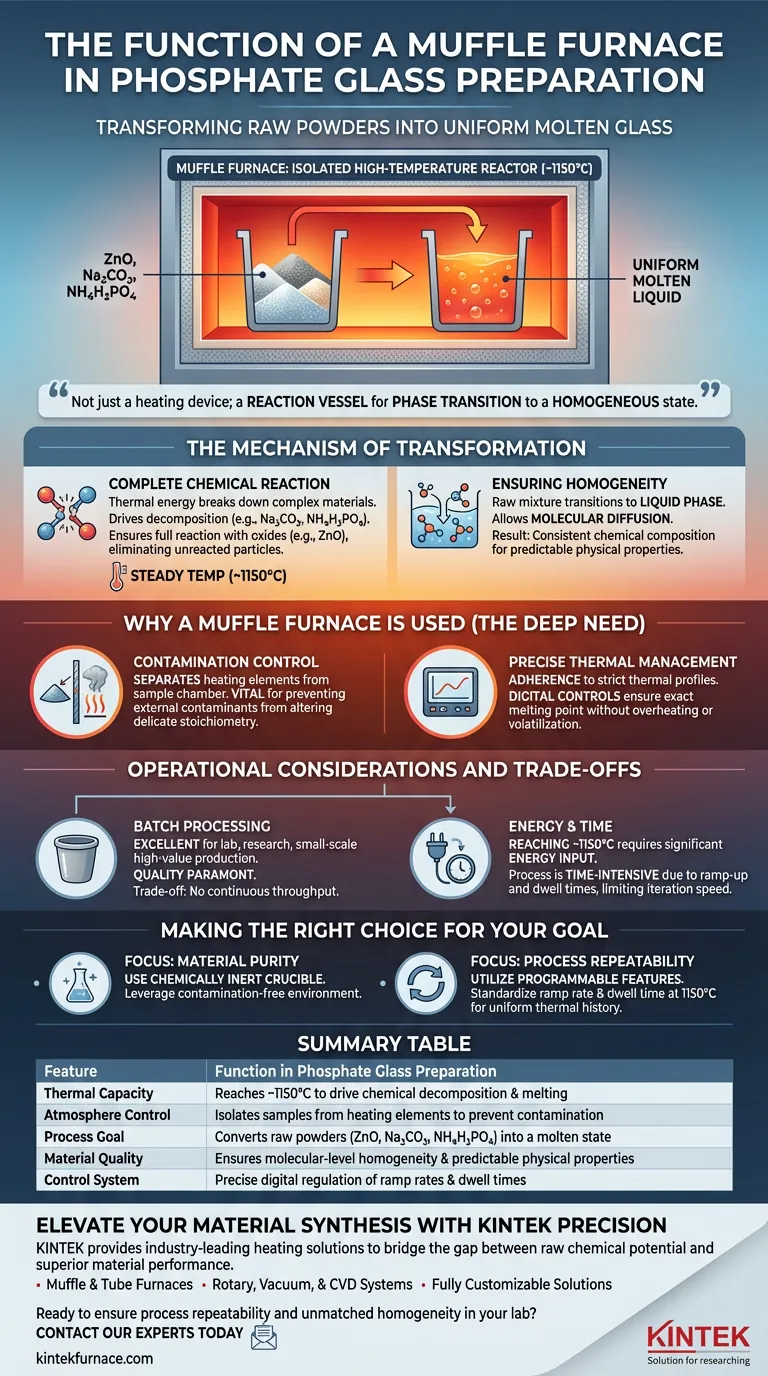

The primary function of a muffle furnace in this context is to provide a stable, isolated high-temperature environment required to chemically transform raw powder mixtures into phosphate glass. Specifically, it heats components such as Zinc Oxide (ZnO), Sodium Carbonate (Na2CO3), and Ammonium Dihydrogen Phosphate (NH4H2PO4) to approximately 1150 °C, ensuring they react completely to form a uniform molten liquid.

The muffle furnace is not merely a heating device; it is a reaction vessel that facilitates the phase transition from solid raw materials to a homogeneous molten state. This thermal uniformity is the fundamental prerequisite for creating high-performance glass powders.

The Mechanism of Transformation

Achieving Complete Chemical Reaction

The preparation of phosphate glass is not simply about melting; it is about driving specific chemical reactions.

The muffle furnace provides the thermal energy required to break down complex raw materials. For example, it drives the decomposition of carbonates (like Na2CO3) and phosphates (like NH4H2PO4).

By maintaining a steady temperature around 1150 °C, the furnace ensures these components react fully with oxides like ZnO. This eliminates unreacted particles that would otherwise compromise the glass's final structure.

Ensuring Homogeneity in the Molten State

Uniformity is the defining characteristic of high-quality glass.

Inside the muffle furnace, the raw mixture transitions into a liquid phase where diffusion can occur. This allows the distinct chemical components to mix at the molecular level.

The result is a "uniform molten state," meaning the chemical composition is consistent throughout the entire batch, which is critical for predictable physical properties in the final product.

Why a Muffle Furnace is Used (The Deep Need)

Contamination Control

A key design feature of a muffle furnace is the separation of the heating elements (and fuel byproducts) from the chamber holding the sample.

In scientific and research applications, this isolation is vital. It prevents external contaminants from altering the delicate stoichiometry of the phosphate glass mixture.

Precise Thermal Management

Creating high-performance materials requires adherence to strict thermal profiles.

Muffle furnaces are typically equipped with digital controls that allow for precise temperature regulation. This ensures the glass reaches the exact melting point without overheating, which could lead to volatilization of certain components.

Operational Considerations and Trade-offs

While muffle furnaces are essential for high-quality synthesis, they present specific operational realities.

Batch Processing vs. Continuous Flow

Muffle furnaces are inherently designed for batch processing.

They are excellent for laboratory settings, research, or small-scale high-value production where quality is paramount. However, they do not offer the continuous throughput found in large industrial tank furnaces.

Energy Consumption and Time

Reaching and maintaining 1150 °C requires significant energy input.

Furthermore, the process is time-intensive. The ramp-up time and the dwell time required to ensure the entire mass is uniformly heated can be substantial, limiting the speed of iteration during material testing.

Making the Right Choice for Your Goal

When utilizing a muffle furnace for phosphate glass preparation, your operational focus dictates your approach.

- If your primary focus is Material Purity: Ensure your crucible material is chemically inert relative to the phosphate melt to leverage the furnace's contamination-free environment.

- If your primary focus is Process Repeatability: Utilize the programmable features to standardize the ramp rate and dwell time at 1150 °C, ensuring every batch undergoes the exact same thermal history.

The muffle furnace serves as the bridge between raw chemical potential and realized material performance, turning a mixture of distinct powders into a unified, high-performance glass matrix.

Summary Table:

| Feature | Function in Phosphate Glass Preparation |

|---|---|

| Thermal Capacity | Reaches ~1150°C to drive chemical decomposition and melting |

| Atmosphere Control | Isolates samples from heating elements to prevent contamination |

| Process Goal | Converts raw powders (ZnO, Na2CO3, NH4H2PO4) into a molten state |

| Material Quality | Ensures molecular-level homogeneity and predictable physical properties |

| Control System | Precise digital regulation of ramp rates and dwell times |

Elevate Your Material Synthesis with KINTEK Precision

High-performance phosphate glass demands absolute purity and precise thermal profiles. KINTEK provides the industry-leading heating solutions needed to bridge the gap between raw chemical potential and superior material performance.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of lab high-temp furnaces, including:

- Muffle & Tube Furnaces for contamination-free batch processing.

- Rotary, Vacuum, & CVD Systems for specialized material transformations.

- Fully Customizable Solutions tailored to your unique research or production needs.

Ready to ensure process repeatability and unmatched homogeneity in your lab? Contact our technical experts today to find the perfect furnace for your application.

Visual Guide

References

- Highly Stable Low‐Temperature Phosphate Glass as a Platform for Multimaterial 3D Printing of Integrated Functional Microfluidic Devices. DOI: 10.1002/adem.202501603

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a muffle furnace play in the preparation of ER-SnmCunOx-t/CC electrocatalysts? Achieve Optimal Purity

- What is important about chamber size in muffle furnaces? Ensure Accurate Heating with the Right Zone

- What environmental testing applications involve muffle furnaces? Achieve Accurate Soil and Water Analysis

- What specific PPE is recommended for loading and unloading a benchtop furnace? Essential Gear for Safe High-Temperature Handling

- How does temperature control work in modern muffle furnaces? Achieve Unmatched Precision and Efficiency

- What role does a high-temperature muffle furnace play in the preparation of SrNbO3 ceramic targets? Synthesis Explained

- How do the costs of industrial muffle furnaces and drying ovens compare? Understand the Price Gap and Choose Wisely

- What critical environmental conditions does a muffle furnace provide for aluminum cast iron? Optimize Your Heat Treatment