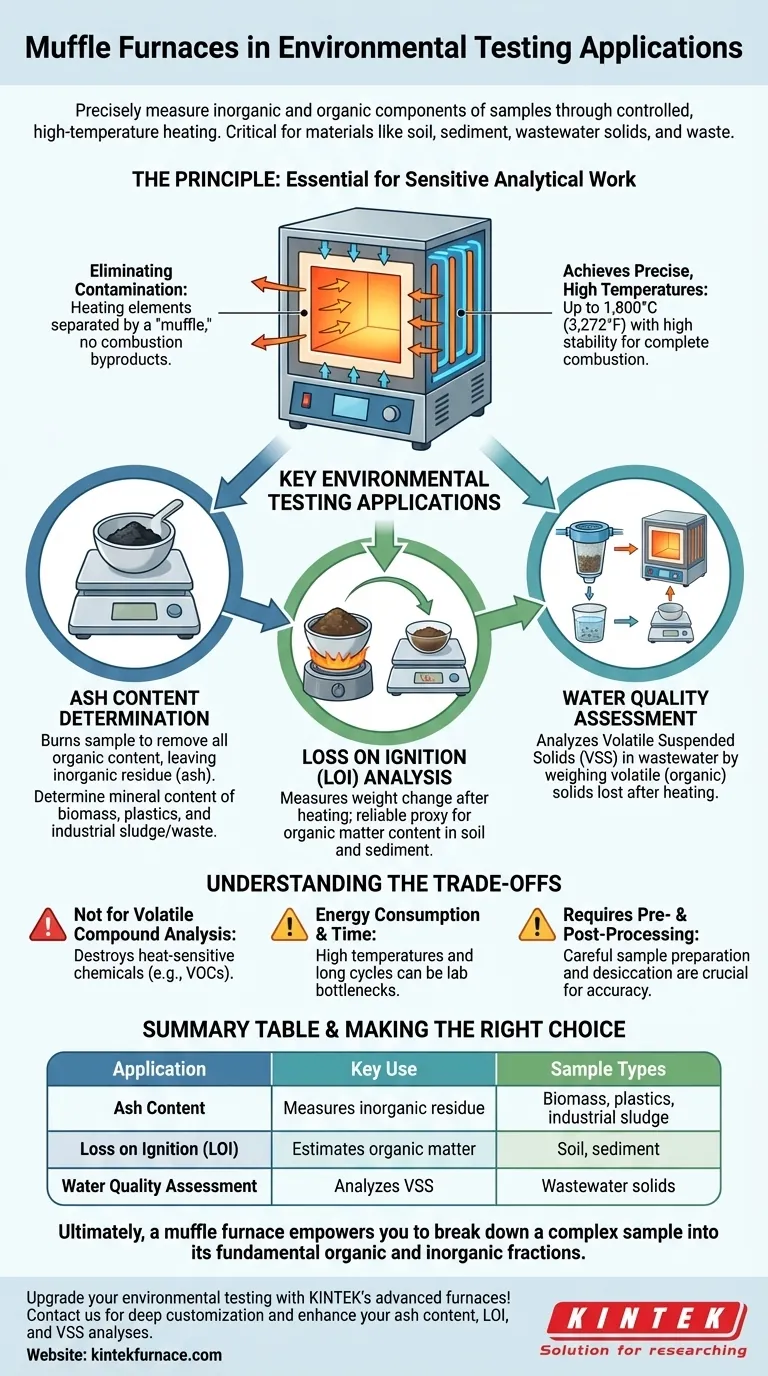

In environmental testing, the primary applications for muffle furnaces are to precisely measure the inorganic and organic components of a sample through controlled, high-temperature heating. The main techniques are ash content determination and Loss on Ignition (LOI) analysis, which are critical for evaluating materials like soil, sediment, wastewater solids, and various forms of waste.

The core value of a muffle furnace in environmental science is its ability to provide a clean, contaminant-free heating environment. This allows analysts to burn away organic material at high temperatures, thereby isolating and quantifying the stable, inorganic components of a sample with high accuracy.

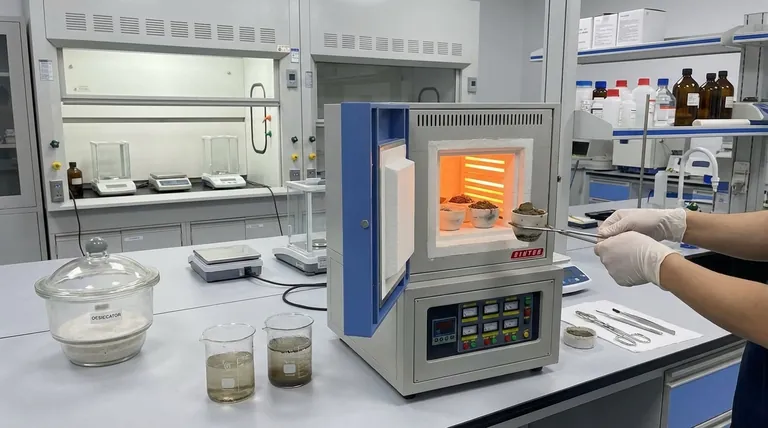

The Principle: Why a Muffle Furnace is Essential

A muffle furnace is fundamentally a high-temperature oven with a key feature: the heating elements are separated from the internal chamber by a "muffle," or retort. This design is what makes it indispensable for sensitive analytical work.

Eliminating Contamination

Modern electric muffle furnaces heat samples via conduction, convection, and radiation. Because the heating elements are outside the chamber, there are no combustion byproducts (like soot or gases) introduced that could contaminate the sample and skew results.

Achieving Precise, High Temperatures

These furnaces can reach temperatures up to 1,800°C (3,272°F) with high stability. This allows for complete combustion of organic matter and specific chemical changes, which are the basis for key environmental tests.

Key Environmental Testing Applications

While muffle furnaces have broad industrial uses in ceramics and metallurgy, their role in environmental testing is focused on compositional analysis.

Ash Content Determination

Ashing is the process of burning a sample to remove all organic content, leaving behind only the inorganic, non-combustible residue (ash).

This is used to determine the mineral content of biomass, the filler content in plastics, or the inorganic composition of industrial sludge and waste materials.

Loss on Ignition (LOI) Analysis

Loss on Ignition is a widely used test that measures the change in mass of a sample after it has been heated to a high temperature.

This weight loss is primarily attributed to the combustion of organic matter and the breakdown of volatile salts. In soil science and ecology, LOI is a reliable proxy for the organic matter content of soil or sediment, a key indicator of soil health and nutrient cycling.

Water Quality Assessment

Muffle furnaces are critical for analyzing solids in water and wastewater. The test for Volatile Suspended Solids (VSS) is a standard method for assessing water quality.

First, a water sample is filtered to capture Total Suspended Solids (TSS). The filter is then placed in a muffle furnace. The weight lost after heating represents the volatile (mostly organic) solids, providing insight into the biological or waste content in the water.

Understanding the Trade-offs

While powerful, a muffle furnace is a specific tool with limitations that are important to recognize for proper application.

Not for Volatile Compound Analysis

The extreme heat completely destroys the compounds it is designed to measure (like organic matter). It is therefore unsuitable for analyzing volatile organic compounds (VOCs) or other heat-sensitive chemicals.

Energy Consumption and Time

Reaching and maintaining temperatures of 550°C or higher requires significant electrical energy. Furthermore, heating, dwelling, and cooling cycles can take several hours, which can be a bottleneck for labs with high sample throughput.

Requires Pre- and Post-Processing

Accurate results depend on careful sample preparation, including drying to a constant weight before ignition and cooling in a desiccator afterward to prevent moisture reabsorption, which would alter the final weight.

Making the Right Choice for Your Goal

To apply this correctly, match the furnace's capability directly to your analytical question.

- If your primary focus is quantifying organic matter in soil or sediment: Use Loss on Ignition (LOI) to measure the weight change after heating, which serves as a direct proxy for organic content.

- If your primary focus is determining the inorganic mineral content of waste or biomass: Use ash content analysis to completely burn off all combustible material and isolate the non-volatile residue for weighing.

- If your primary focus is analyzing solids in wastewater: Use the furnace to perform a Volatile Suspended Solids (VSS) test on a filtered sample to differentiate the organic fraction from the inert mineral solids.

Ultimately, a muffle furnace empowers you to break down a complex sample into its fundamental organic and inorganic fractions.

Summary Table:

| Application | Key Use | Sample Types |

|---|---|---|

| Ash Content Determination | Measures inorganic residue after burning | Biomass, plastics, industrial sludge |

| Loss on Ignition (LOI) | Estimates organic matter via weight loss | Soil, sediment |

| Water Quality Assessment | Analyzes volatile suspended solids (VSS) | Wastewater solids |

Upgrade your environmental testing with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing accuracy in ash content, LOI, and VSS analyses. Contact us today to discuss how our furnaces can optimize your lab's efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency