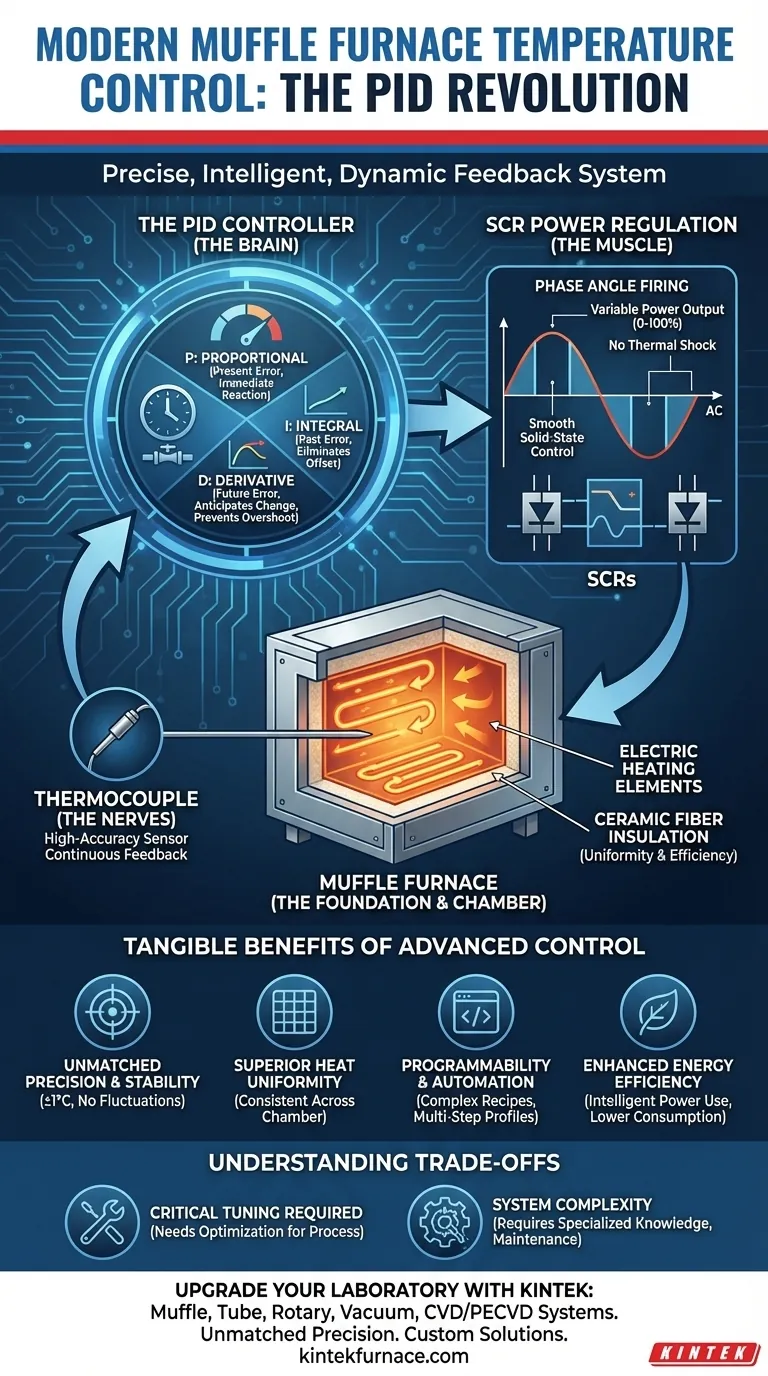

In modern muffle furnaces, temperature control is achieved not by a simple thermostat, but through a dynamic digital feedback system. At its core is a PID (Proportional-Integral-Derivative) controller that continuously measures the furnace's temperature, compares it to your desired setpoint, and intelligently adjusts the power sent to the electric heating elements in real time. This ensures exceptionally high precision, stability, and efficiency.

The key to modern temperature control is the transition from a simple on/off switch to an intelligent, predictive system. A PID controller doesn't just react to the current temperature; it anticipates changes and makes smooth, continuous adjustments to prevent overshooting the target and maintain a highly stable thermal environment.

How the Modern Control Loop Works

The remarkable precision of a modern muffle furnace is the result of several sophisticated components working in perfect harmony. This closed-loop system constantly measures, calculates, and adjusts to maintain your exact temperature parameters.

The Brain: The PID Controller

The PID algorithm is the intelligence behind the entire operation. It breaks down its decision-making into three distinct parts to calculate the exact power output needed.

- Proportional (P): This is the primary response. The further the current temperature is from the setpoint, the more power the controller applies. It's a direct reaction to the present error.

- Integral (I): This component corrects for small, lingering errors over time. It looks at the past error and slowly increases power to eliminate any "droop" or offset that the proportional response alone might allow.

- Derivative (D): This is the predictive element. By analyzing the rate of temperature change, it anticipates when the furnace will reach its setpoint and begins to reduce power before it gets there. This prevents overshoot and stabilizes the temperature much faster.

The Muscle: Power Regulation with SCRs

The PID controller's decision is executed by a power regulator. Instead of a crude on/off relay, modern furnaces use Silicon Controlled Rectifiers (SCRs).

Think of an SCR as a highly precise, solid-state dimmer switch. It uses a technique called phase angle firing to minutely chop up the AC power wave, allowing it to deliver a smooth, variable amount of power to the heating elements—anywhere from 0% to 100%. This is far superior to the thermal shock and instability caused by an "all-or-nothing" approach.

The Nerves: High-Accuracy Sensors

For the PID controller to work, it needs constant, accurate feedback. This is provided by a thermocouple, a sensor placed inside the furnace chamber that measures the temperature and reports it back to the controller hundreds or thousands of times per minute.

The Foundation: Controllable Electric Heat

This entire system is only possible because modern furnaces use high-temperature electric heating elements, such as those made from silicon carbide. Unlike older combustion methods, electric heat is clean, contained, and inherently controllable, allowing for the precise power adjustments dictated by the PID system.

The Tangible Benefits of Advanced Control

This sophisticated system delivers clear, practical advantages that are critical for scientific and industrial applications.

Unmatched Precision and Stability

The primary benefit is holding an incredibly stable temperature. A well-tuned PID system can minimize fluctuations to within a single degree of the setpoint, preventing temperature swings that could ruin a sensitive process.

Superior Heat Uniformity

When combined with modern ceramic fiber insulation, which minimizes heat loss, PID control helps ensure the entire chamber is at a uniform temperature. This eliminates hot or cold spots that can lead to inconsistent results.

Programmability and Automation

Modern digital controllers allow for complex, multi-step heating profiles. Users can program a "recipe" with dozens of segments—for example, ramp up to 600°C, hold for two hours, ramp to 900°C, hold for five hours, and then cool down at a controlled rate. This automates entire processes with perfect repeatability.

Enhanced Energy Efficiency

PID control intrinsically saves energy by preventing wasteful overheating. Furthermore, many furnaces feature intelligent modes that automatically adjust heating speed or reduce power output once a set temperature is reached, maintaining stability with minimal energy consumption.

Understanding the Trade-offs

While incredibly powerful, this technology is not without its considerations. Objectivity requires acknowledging them.

The Critical Role of PID Tuning

A PID controller is only as good as its tuning. If the P, I, and D values are not optimized for the specific furnace and its typical load, it can perform poorly, causing temperature oscillations or a sluggish response. While most furnaces come with excellent factory tuning, significant changes in your process may require an adjustment.

System Complexity and Maintenance

Advanced digital controllers and SCRs are more complex than simple mechanical relays. While highly reliable, diagnosing a fault or replacing a component can be more costly and require more specialized knowledge.

Matching Features to Your Actual Need

The allure of a 30-segment programmable controller with remote monitoring is strong. However, if your work only involves heating samples to a single temperature, these advanced features represent unnecessary complexity and cost. It's crucial to align the furnace's capabilities with your true operational requirements.

Making the Right Choice for Your Goal

When selecting a furnace, focus on how its control system serves your specific application.

- If your primary focus is process repeatability and certification: Prioritize a furnace with a well-tuned, programmable PID controller and features like data logging to validate your thermal profiles.

- If your primary focus is high-throughput production: Look for a furnace with a fast-ramping PID profile and robust SCRs designed for continuous, heavy-duty cycling.

- If your primary focus is energy efficiency and operational cost: Seek out models that explicitly combine PID control with advanced ceramic fiber insulation and high-efficiency heating elements.

- If your primary focus is operational simplicity for basic heat treatments: A standard PID controller with a clear digital interface is more than sufficient; advanced multi-segment programmability is likely unnecessary.

Understanding the principles of modern temperature control empowers you to select not just a furnace, but the precise thermal instrument your work demands.

Summary Table:

| Component | Function | Benefit |

|---|---|---|

| PID Controller | Adjusts power based on error, integral, and derivative calculations | High precision and stability, prevents overshoot |

| SCRs (Silicon Controlled Rectifiers) | Regulates power smoothly via phase angle firing | Efficient heating, reduces thermal shock |

| Thermocouple | Measures temperature continuously for feedback | Accurate real-time monitoring |

| Electric Heating Elements | Provides controllable heat source | Clean, uniform heating for consistent results |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering unmatched precision, efficiency, and repeatability. Contact us today to discuss how our tailored solutions can optimize your thermal processes and drive better outcomes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO