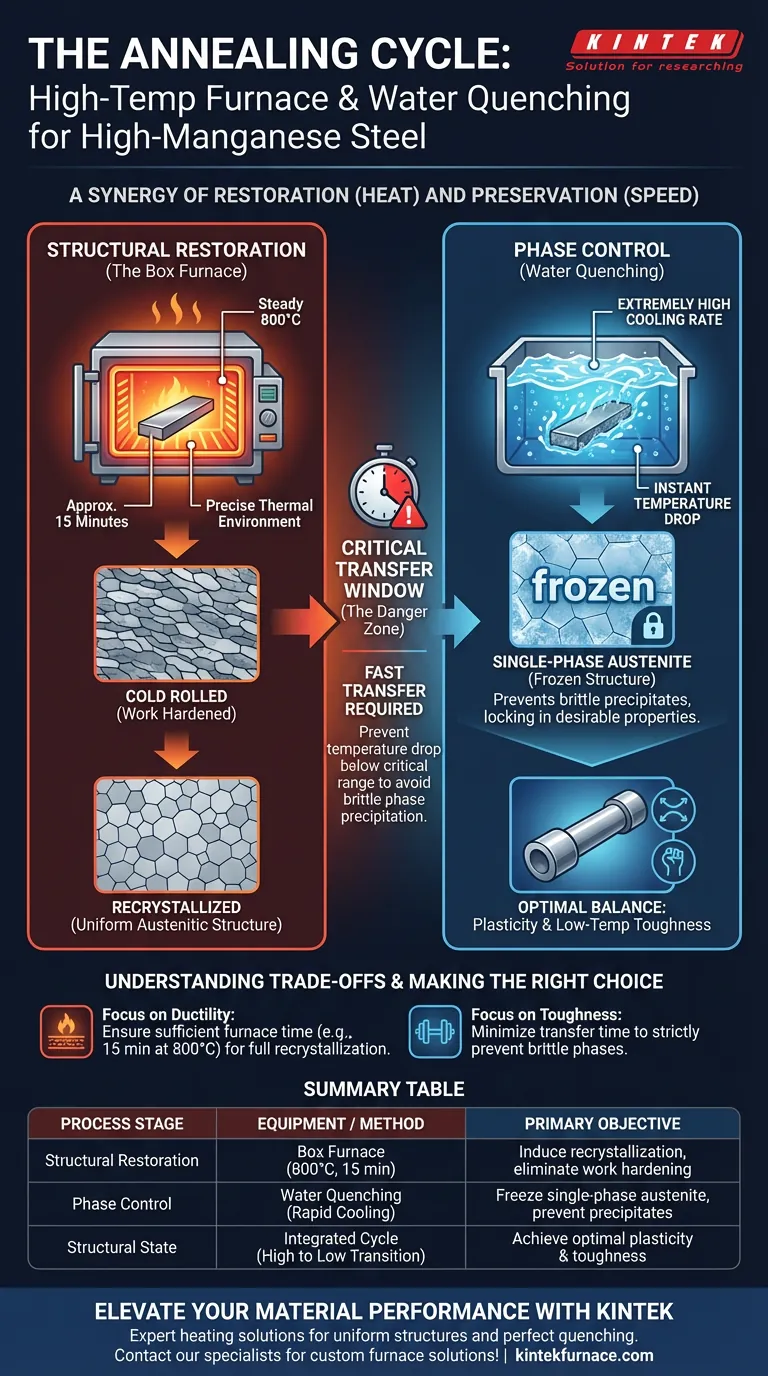

The collaboration between a high-temperature box furnace and water quenching is defined by a cycle of restoration and preservation. The laboratory furnace heats the steel to a stable 800°C, inducing full recrystallization to reverse the effects of cold rolling and eliminate work hardening. Immediately following this heating phase, water quenching applies a rapid cooling rate to "freeze" the metal's internal structure, preventing the formation of brittle phases and locking in the desirable single-phase austenite.

This process relies on the furnace to restore the microstructure through heat and the quench to preserve that structure through speed. Together, they transform work-hardened steel into a material with an optimal balance of plasticity and low-temperature toughness.

The Role of the Box Furnace: Structural Restoration

The first stage of the annealing process is strictly about correcting the microstructure deformities caused by previous processing, such as cold rolling.

Inducing Complete Recrystallization

The laboratory box furnace provides a precise thermal environment, maintaining a steady 800°C.

At this specific temperature, the deformed grain structures within the steel begin to reorganize. This thermal input is necessary to nucleate and grow new, strain-free grains, replacing the distorted ones.

Eliminating Work Hardening

Cold rolling increases strength but severely reduces ductility, a phenomenon known as work hardening.

By holding the steel at temperature—typically for around 15 minutes—the furnace relieves internal stresses. This transforms the material into a uniform austenitic fine-grain structure, which is the foundation for ductility.

The Role of Water Quenching: Phase Control

While the furnace prepares the structure, the quenching phase is responsible for capturing it. The success of the entire process hinges on the speed of this transition.

Freezing Single-Phase Austenite

Upon exiting the furnace, the steel is in a single-phase austenite state, which is stable at high temperatures but unstable as it cools slowly.

Water quenching utilizes an extremely high cooling rate. This instantly drops the temperature of the steel, forcing the high-temperature structure to remain stable even at room temperature.

Preventing Brittle Precipitation

If the steel were allowed to cool slowly (air cooling), carbides or other brittle phases would precipitate out of the solid solution.

These precipitates act as stress concentrators that weaken the material. Rapid quenching suppresses this precipitation entirely, ensuring the steel retains the plasticity and toughness required for low-temperature applications.

Understanding the Trade-offs

While this combination of heating and rapid cooling is effective, it introduces specific processing risks that must be managed.

The Transfer Time Window

The critical danger zone is the physical transfer from the furnace to the water bath.

If this transfer is too slow, the temperature of the steel will drop below the critical range before it hits the water. This allows partial precipitation of brittle phases, rendering the subsequent quench ineffective.

Thermal Shock and Geometry

Water quenching induces massive thermal shock due to the rapid temperature difference.

While high-manganese steel generally handles this well, components with complex geometries or varying thicknesses may experience warping or residual stress if not submerged uniformly.

Making the Right Choice for Your Goal

To achieve superior mechanical properties in high-manganese steel, you must treat the heating and cooling steps as a single, continuous operation.

- If your primary focus is restoring ductility: Ensure the furnace holding time is sufficient (e.g., 15 minutes at 800°C) to guarantee complete recrystallization of the grain structure.

- If your primary focus is low-temperature toughness: Minimize the transfer time between the furnace and the water bath to strictly prevent the precipitation of brittle phases.

By mastering the timing between thermal restoration and rapid solidification, you ensure your material performs reliably even in demanding environments.

Summary Table:

| Process Stage | Equipment / Method | Temperature & Time | Primary Objective |

|---|---|---|---|

| Structural Restoration | Box Furnace | 800°C for 15 minutes | Induce full recrystallization and eliminate work hardening |

| Phase Control | Water Quenching | Rapid Cooling (Instant) | Freeze single-phase austenite and prevent brittle precipitation |

| Structural State | Integrated Cycle | High to Low Transition | Achieve optimal plasticity and low-temperature toughness |

Elevate Your Material Performance with KINTEK

Precision annealing of high-manganese steel requires flawless thermal consistency and rapid processing. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces designed to meet your unique metallurgical needs.

Our advanced heating solutions ensure uniform grain structures, while our expert-engineered designs minimize transfer times for perfect quenching results. Transform your lab's efficiency today—Contact our specialists now to find your custom furnace solution!

Visual Guide

References

- Lu, Shao-Lun, Max-Planck-Institut für Nachhaltige Materialien. Making High Mn Steel by Sustainable Ferromanganese Pre-alloy for Cryogenic Applications. DOI: 10.5281/zenodo.17520991

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the common uses of muffle furnaces? Essential for Material Analysis, Heat Treatment, and Synthesis

- Why is proper ventilation important when using a benchtop furnace? Protect Your Lab from Harmful Fumes

- What is the necessity of cleaning and drying activated carbon supports in a muffle furnace? Unlock Peak Catalyst Performance

- Why do conventional furnaces require long holding times for BCZY712 sintering? Overcome Heat Efficiency Challenges

- How are box type resistance furnaces applied in electronic ceramics manufacturing? Essential for Precision Sintering and Polarization

- What are the advantages of a box type electric furnace? Achieve Precise, Safe Thermal Processing

- Why is an industrial high-temperature furnace required for chemical activation? Achieve 700°C Precision for Carbon

- What is the difference between a retort and a muffle furnace? Choose the Right Atmosphere-Controlled Furnace