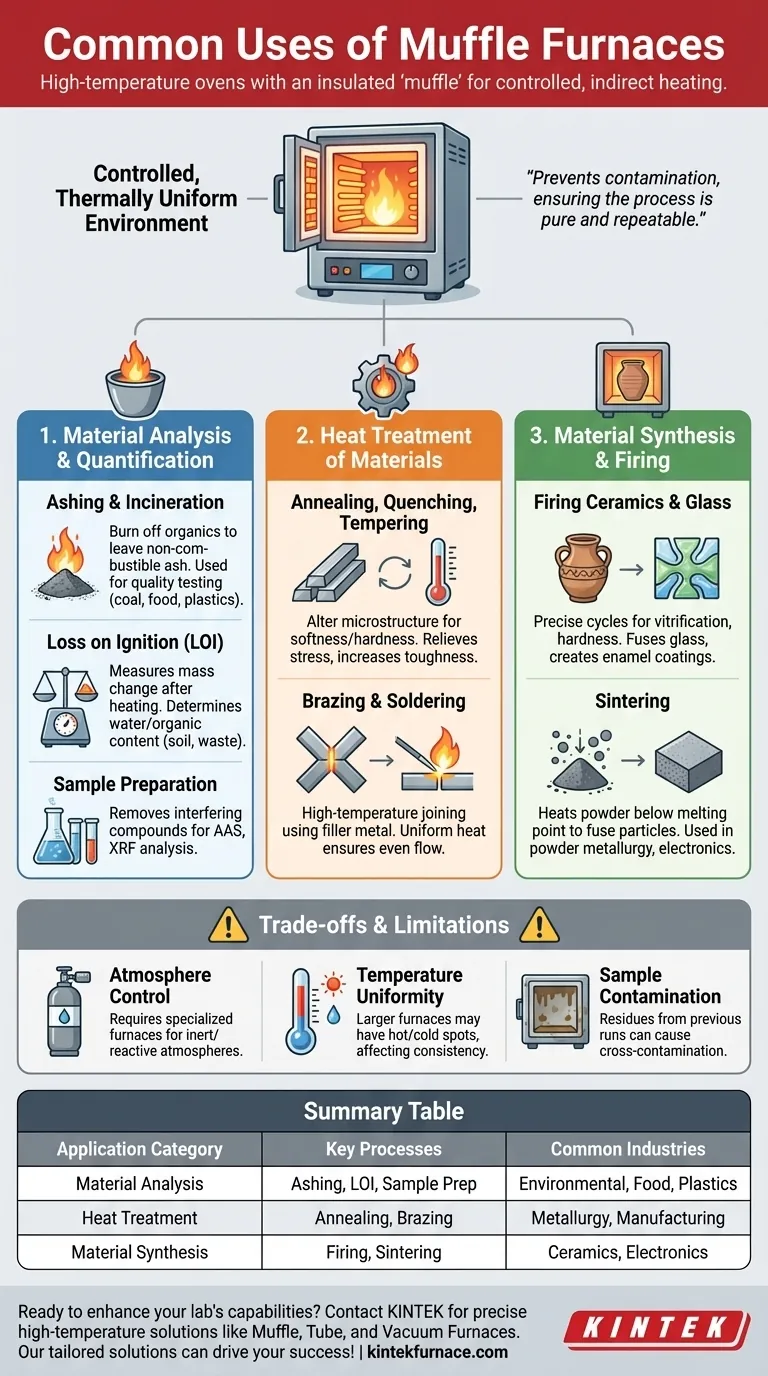

At its core, a muffle furnace is a high-temperature oven with a critical distinction. It uses an insulated outer chamber (the "muffle") to heat a sample without exposing it to the direct flame or heating elements. This controlled, indirect heating makes it an indispensable tool for three primary categories of work: quantitatively analyzing a material's composition, modifying a material's physical properties, and synthesizing new materials.

A muffle furnace's primary value is not just its high heat, but its ability to provide a chemically isolated and thermally uniform environment. This prevents contamination from the heating source, ensuring the process—whether for analysis, treatment, or creation—is pure and repeatable.

Core Application 1: Material Analysis and Quantification

The most common analytical use of a muffle furnace is to determine the composition of a sample by burning away its organic or volatile components.

Ashing and Incineration

Ashing is a process that uses extreme heat to burn off all organic substances in a sample. This leaves behind only the non-combustible inorganic material, known as ash.

This technique is fundamental for determining the ash content in materials like coal, petroleum, food products, and plastics, which is a key indicator of quality and composition.

Loss on Ignition (LOI)

Closely related to ashing, Loss on Ignition (LOI) is a quantitative test that measures the change in a sample's mass after being heated to a high temperature.

This is widely used in geochemistry and environmental science to determine the water or organic matter content in soil, sediment, or waste samples.

Sample Preparation for Analysis

In many chemical labs, a muffle furnace is the first step in preparing a sample for more detailed analysis.

By removing interfering organic compounds or pre-concentrating trace metals, the furnace prepares a clean, inorganic sample that can be analyzed by techniques like atomic absorption spectroscopy (AAS) or X-ray fluorescence (XRF).

Core Application 2: Heat Treatment of Materials

A muffle furnace provides the precise temperature control needed to intentionally alter the microstructure and physical properties of metals and alloys.

Annealing, Quenching, and Tempering

These are fundamental metallurgical processes. Annealing involves heating and slow cooling to make a metal softer and less brittle, relieving internal stresses.

Conversely, quenching (rapid cooling) and tempering (reheating to a lower temperature) are used to increase a material's hardness and toughness.

Brazing and Soldering

Muffle furnaces are used for high-temperature joining of metals. Brazing and soldering use a filler metal to bond two pieces of a base metal together.

The furnace provides the uniform heat needed to melt the filler metal and ensure it flows evenly into the joint without melting the base components.

Core Application 3: Material Synthesis and Firing

The furnace's ability to create a clean, high-temperature environment is essential for creating new materials from raw components.

Firing Ceramics and Glass

The production of ceramics, from pottery to advanced technical components, requires a precise heating and cooling cycle to achieve vitrification and hardness.

Similarly, muffle furnaces are used for fusing glass, creating enamel coatings on metal, and other processes where controlled high heat is necessary to form the final product.

Sintering

Sintering is the process of taking a powdered material and heating it to just below its melting point. This causes the particles to fuse together into a solid, coherent mass.

This technique is crucial in powder metallurgy and for creating certain types of high-performance ceramics and electronic components.

Understanding the Trade-offs and Limitations

While powerful, a muffle furnace is not a universal solution. Understanding its limitations is key to using it effectively.

Atmosphere Control

A standard muffle furnace operates in an ambient air atmosphere. If your process requires an inert atmosphere (like argon or nitrogen) or a reactive atmosphere to prevent oxidation, you will need a specialized furnace designed for that purpose.

Temperature Uniformity

While the muffle is designed to improve heat distribution, not all furnaces are equal. In larger furnaces or less expensive models, "hot spots" and "cold spots" can exist, potentially affecting the consistency of your results, especially when processing multiple samples or large parts.

Sample Contamination

The insulated chamber can absorb and retain residues from previous runs. Without proper cleaning protocols, this can lead to cross-contamination, a critical issue in high-purity applications or trace element analysis.

Making the Right Choice for Your Goal

Your intended application dictates which furnace features are most critical.

- If your primary focus is quantitative analysis (ashing, LOI): Prioritize exceptional temperature accuracy and repeatability to ensure your measurements are consistent and defensible.

- If your primary focus is metallurgical heat treatment: Focus on the furnace's ability to execute precise heating and cooling profiles, including controlled ramp rates and soak times.

- If your primary focus is material creation (ceramics, sintering): Ensure the furnace's internal volume and temperature uniformity are adequate for the size and shape of the parts you intend to produce.

Ultimately, understanding these core functions allows you to select the precise thermal process required to achieve your material goals.

Summary Table:

| Application Category | Key Processes | Common Industries |

|---|---|---|

| Material Analysis | Ashing, Loss on Ignition, Sample Preparation | Environmental Science, Geochemistry, Food, Plastics |

| Heat Treatment | Annealing, Quenching, Tempering, Brazing | Metallurgy, Manufacturing |

| Material Synthesis | Firing Ceramics, Sintering, Glass Fusing | Ceramics, Electronics, Powder Metallurgy |

Ready to enhance your laboratory's capabilities with precise high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for material analysis, heat treatment, or synthesis. Contact us today to discuss how our tailored solutions can drive your success!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity