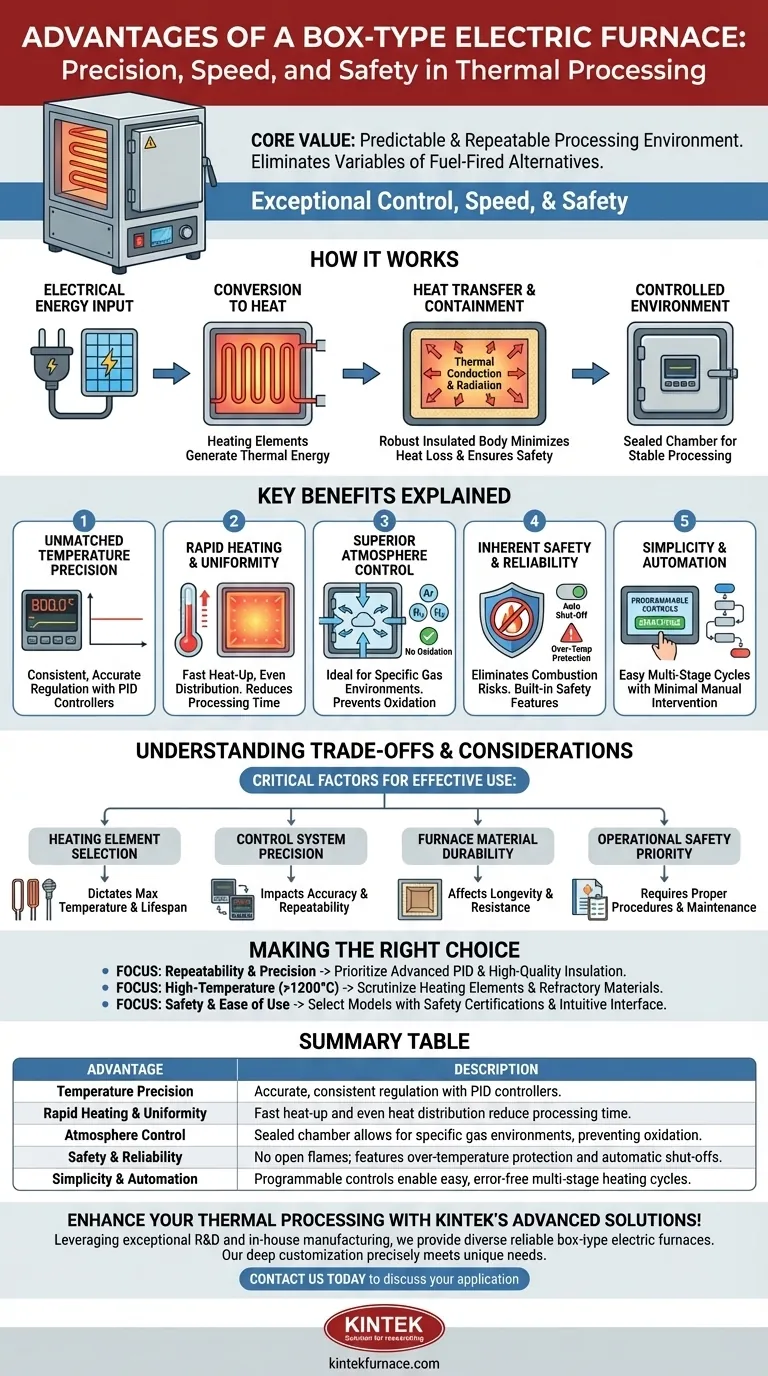

At its core, a box-type electric furnace offers exceptional control, speed, and safety for a wide range of thermal processing applications. Its primary advantages stem from its ability to precisely manage temperature and atmosphere in a self-contained, automated, and reliable unit, making it a cornerstone tool in laboratories and specialized manufacturing.

The true value of a box-type electric furnace is not just its heating capability, but its function as a highly predictable and repeatable processing environment. Its advantages are a direct result of its simple, electrically-driven design, which eliminates many variables associated with fuel-fired alternatives.

How the Furnace Achieves Its Advantages

A box-type electric furnace operates on a straightforward principle: converting electrical energy into heat. Understanding this simple mechanism is key to appreciating its benefits.

The Conversion of Energy to Heat

Heating elements within the furnace, typically made of high-resistance alloys, generate thermal energy when an electric current is passed through them. This heat is then transferred to the materials inside the furnace chamber through a combination of thermal conduction and radiation.

Containing the Heat Effectively

The furnace body is constructed from robust materials like high-temperature alloy steel, with a thick internal insulation layer. This design minimizes heat loss, maximizes energy efficiency, and ensures the exterior remains at a safe temperature. The insulated door seals the chamber, creating a contained and stable environment.

Key Benefits Explained

The furnace's design directly translates into several significant operational advantages over other heating methods.

Unmatched Temperature Precision

Because the energy input is electrical, it can be regulated with extreme accuracy. Modern furnaces use sophisticated PID (Proportional-Integral-Derivative) controllers that automatically adjust power to maintain the set temperature with minimal deviation, ensuring process consistency.

Rapid Heating and Uniformity

Unlike fuel-fired systems that require significant pre-heating, electric elements can reach target temperatures very quickly. The controlled environment of the sealed chamber also promotes uniform heat distribution, reducing hot and cold spots on the workpiece.

Superior Atmosphere Control

The sealed chamber is ideal for maintaining a specific atmosphere. This is critical for processes where oxidation must be prevented or where reactions require a specific gas environment. This level of control is difficult to achieve in an open-flame system.

Inherent Safety and Reliability

Box-type electric furnaces eliminate the risks associated with combustible fuels, open flames, and carbon monoxide emissions. They are equipped with multiple safety features, such as over-temperature protection and automatic shut-offs, making them exceptionally safe and reliable for unattended operation.

Simplicity and Automation

Most models feature simple, programmable controls for temperature and time. This automation allows users to run complex, multi-stage heating cycles with minimal manual intervention, reducing the chance of human error and improving productivity.

Understanding the Trade-offs and Considerations

While highly advantageous, the effectiveness of a box furnace depends entirely on selecting a unit with the correct specifications for your needs.

Heating Element Selection is Critical

The material of the heating element dictates the furnace's maximum operating temperature and lifespan. Different applications require different elements, and this is a primary factor in the furnace's cost and capability.

The Control System Defines Precision

The quality of the temperature control system directly impacts the precision and repeatability of your process. For high-stakes applications, an advanced controller is not a luxury but a necessity.

Furnace Materials Determine Durability

The materials used for the internal furnace chamber and the external body affect the furnace's longevity, maximum temperature rating, and resistance to chemical corrosion from off-gassing materials.

Always Prioritize Operational Safety

Despite built-in protections, safe operation is paramount. Always check that the furnace is clean, the power supply is correct, and operating procedures are followed to prevent damage to the unit or the workpiece.

Making the Right Choice for Your Application

Use your primary goal to guide your selection process.

- If your primary focus is process repeatability and precision: Prioritize a furnace with an advanced PID temperature control system and high-quality thermal insulation.

- If your primary focus is high-temperature applications (above 1200°C): Scrutinize the specifications of the heating elements (e.g., silicon carbide) and the chamber's refractory materials.

- If your primary focus is safety and ease of use: Select a model with comprehensive safety certifications, automated shut-off features, and an intuitive user interface.

By matching the furnace's specific capabilities to your application's demands, you can ensure it becomes a reliable and effective tool for your work.

Summary Table:

| Advantage | Description |

|---|---|

| Temperature Precision | Uses PID controllers for accurate, consistent temperature regulation. |

| Rapid Heating & Uniformity | Fast heat-up times and even heat distribution reduce processing time. |

| Atmosphere Control | Sealed chamber allows for specific gas environments, preventing oxidation. |

| Safety & Reliability | No open flames; features over-temperature protection and automatic shut-offs. |

| Simplicity & Automation | Programmable controls enable easy, error-free multi-stage heating cycles. |

Enhance your thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable box-type electric furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior performance and efficiency. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- Why is a laboratory high-temperature box furnace essential for KNN ceramic powders? Mastering Solid-State Synthesis

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance