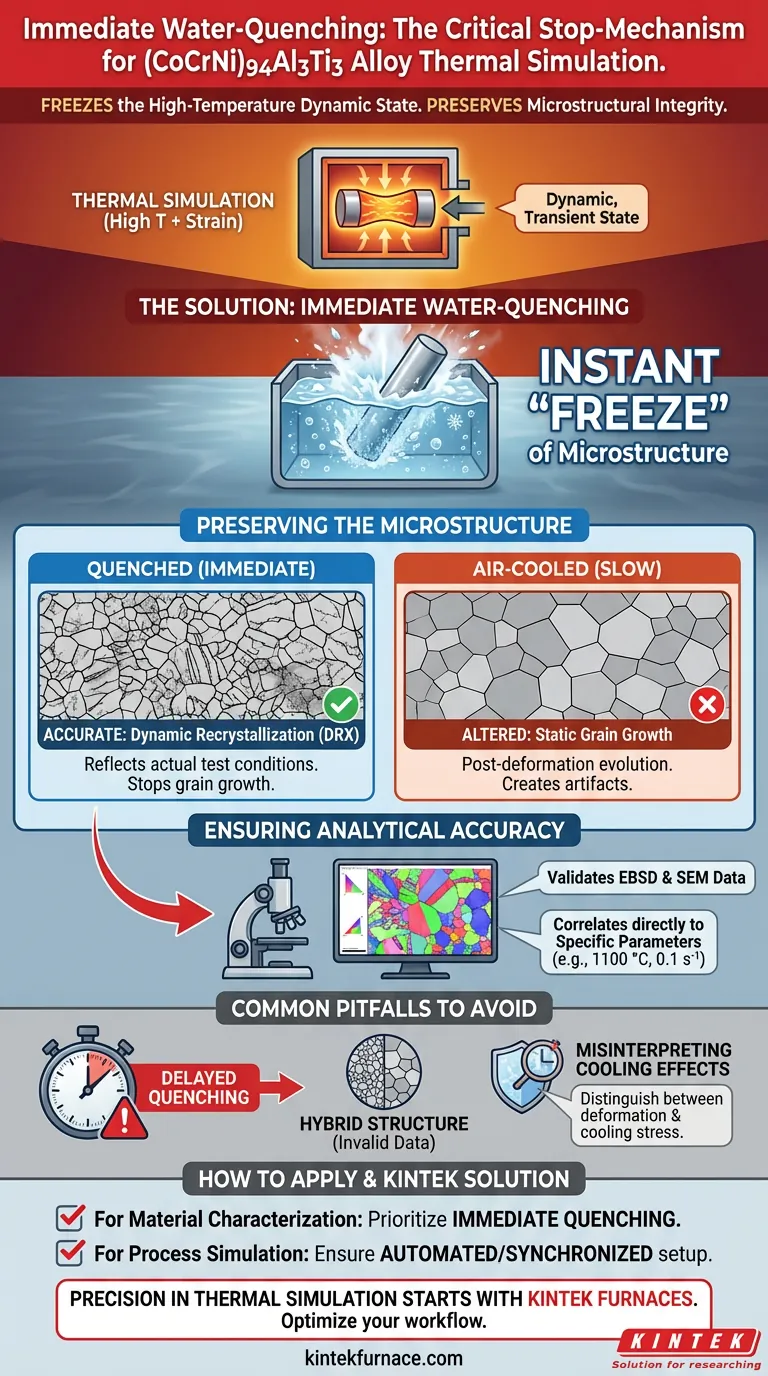

Immediate water-quenching is the critical stop-mechanism required to preserve the integrity of thermal simulation experiments. For (CoCrNi)94Al3Ti3 alloy specimens, this rapid cooling is essential to instantly "freeze" the internal structure of the metal as it exists at high temperatures, preventing natural thermal evolution that occurs the moment deformation stops.

Core Takeaway When an alloy is deformed at high heat, its internal structure is in a dynamic, transient state. Immediate water-quenching halts all thermal activity to preserve the specific Dynamic Recrystallization (DRX) microstructure, ensuring that subsequent analysis reflects the actual test conditions rather than cooling artifacts.

Preserving the Transient Microstructure

Freezing Dynamic Recrystallization (DRX)

During thermal simulation, the alloy undergoes a process called Dynamic Recrystallization (DRX). This microstructural change is driven by the specific combination of heat and mechanical strain applied during the test. Water-quenching utilizes rapid cooling rates to capture this exact state, locking the microstructure in place before it can relax or change.

Preventing Static Grain Growth

If the specimen is allowed to cool slowly (air cooling), the internal grains will continue to evolve. This post-deformation phenomenon is known as static grain growth. By immediately lowering the temperature, you remove the thermal energy required for this growth, ensuring the grain size remains exactly as it was at the moment deformation ceased.

Ensuring Analytical Accuracy

Validating EBSD and SEM Data

Advanced imaging techniques, such as Electron Backscatter Diffraction (EBSD) and Scanning Electron Microscopy (SEM), are used to analyze the alloy's behavior. These tools are extremely sensitive and detect minute details in grain orientation and boundary structure. If the sample is not quenched, the images produced will represent a "relaxed" state, rendering the data factually incorrect regarding the test conditions.

Correlating Data to Specific Parameters

To understand how the alloy behaves under precise conditions, the final microstructure must map directly to the input parameters. For example, when testing at 1100 °C with a strain rate of 0.1 s⁻¹, the resulting structure is unique to those variables. Quenching guarantees that the observed physical properties are the direct result of those specific inputs, not a byproduct of uncontrolled cooling.

Common Pitfalls to Avoid

The Risk of Delayed Quenching

The most critical error in this process is a delay between the cessation of strain and the introduction of water. Even a delay of a few seconds allows the material to retain enough heat for the microstructure to alter. This leads to a hybrid structure—partially dynamic, partially static—which compromises the validity of the entire simulation.

Misinterpreting Cooling Effects

It is vital to distinguish between effects caused by the deformation and effects caused by the cooling method. While quenching is necessary to freeze the structure, one must ensure the analysis focuses on the high-temperature features preserved by the quench, rather than thermal stresses introduced by the rapid temperature drop itself.

How to Apply This to Your Project

To ensure your thermal simulation data is defensible and accurate, consider the following regarding your cooling strategy:

- If your primary focus is material characterization: Prioritize immediate quenching to ensure EBSD/SEM imagery reflects the true high-temperature state of the alloy.

- If your primary focus is process simulation: Ensure your quenching setup is automated or tightly synchronized to eliminate any delay after deformation.

By treating the cooling phase as a critical variable rather than an afterthought, you ensure your data remains a true window into the alloy's high-temperature behavior.

Summary Table:

| Feature | Impact of Immediate Quenching | Impact of Slow Air Cooling |

|---|---|---|

| Microstructure | Preserves Dynamic Recrystallization (DRX) | Suffers Static Grain Growth |

| Thermal State | "Freezes" transient high-temp state | Allows for natural thermal evolution |

| Data Integrity | High: Maps directly to test parameters | Low: Includes cooling artifacts |

| Analytical Value | Validates EBSD and SEM accuracy | Resulting images reflect a "relaxed" state |

| Risk Factor | Minimal structural change | High risk of hybrid, invalid structures |

Precision in thermal simulation requires precision in heating and cooling control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of alloy research and materials science. Ensure your (CoCrNi)94Al3Ti3 specimens yield defensible data with our lab high-temp furnaces. Contact KINTEK today to optimize your thermal simulation workflow!

Visual Guide

References

- Optimized Control of Hot-Working Parameters in Hot-Forged (CoCrNi)94Al3Ti3 Medium-Entropy Alloy. DOI: 10.3390/coatings15060706

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What necessary conditions does a vacuum drying oven provide for geopolymers? Optimize Your Curing and Molding Process

- How does the "Flux Melting" process in MOF glass preparation utilize heating equipment? Low-Temp MOF Vitrification

- What is the role of a laboratory oven in mushroom dehydration? Master Pre-Treatment for Precise Biochemical Analysis

- What is the purpose of analyzing dust from furnace walls using XRD? Confirm Magnesium Evaporation in AM60 Alloy

- What is the temperature of a sintering furnace? From 1100°C to 2200°C+ for Your Material

- What are the process advantages of using a microwave hydrothermal high-pressure reactor? Master V-NbOPO4@rGO Synthesis

- What is the importance of using a vacuum drying oven for MoS2/rGO battery electrodes? Maximize Battery Performance

- What is the purpose of introducing high-purity argon gas into an immersed probe? Enhance Melt Analysis Accuracy