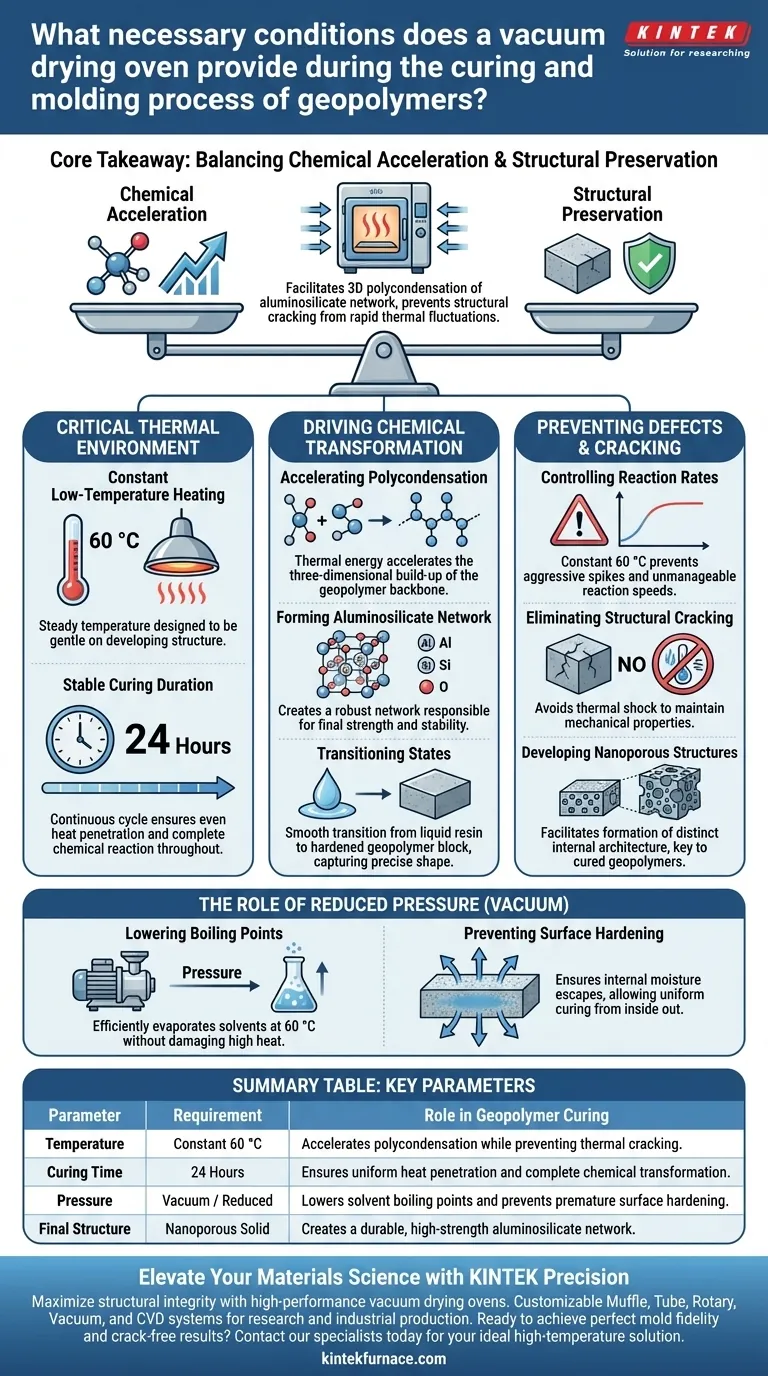

A vacuum drying oven provides a highly controlled environment characterized by constant low-temperature heating at 60 °C and a stable curing duration of 24 hours. This specific combination creates the ideal conditions for geopolymer resins to undergo the necessary chemical transformations without suffering from physical defects. By maintaining a stable thermal atmosphere, the oven ensures the material transitions uniformly from a liquid state to a solid, hardened block.

Core Takeaway The vacuum drying oven balances chemical acceleration with structural preservation. It facilitates the three-dimensional polycondensation of the aluminosilicate network while strictly controlling the temperature to prevent the structural cracking often caused by rapid thermal fluctuations.

Establishing the Critical Thermal Environment

To achieve a successful mold, specific thermal parameters must be maintained rigourously.

Constant Low-Temperature Heating

The oven maintains a steady temperature of 60 °C. This is considered a "low-temperature" approach relative to other ceramic firing processes, designed to be gentle on the developing structure.

Stable Curing Duration

The process requires a continuous 24-hour cycle. This extended duration ensures that the heat penetrates the material evenly, allowing the chemical reaction to reach completion throughout the entire volume of the resin.

Driving the Chemical Transformation

The heat provided by the oven is not merely for drying; it is the catalyst for the material's fundamental structural change.

Accelerating Polycondensation

The thermal energy accelerates the three-dimensional polycondensation process. This reaction builds the backbone of the geopolymer material.

Forming the Aluminosilicate Network

Under these specific conditions, the resin forms a robust aluminosilicate network. This network is responsible for the material's final strength and stability.

Transitioning States

The process allows for a smooth transition from a liquid resin to a hardened geopolymer block. This gradual hardening is essential for capturing the precise shape of the mold.

Preventing Defects and Cracking

The primary reason for using a specialized vacuum oven rather than standard heating methods is the preservation of structural integrity.

Controlling Reaction Rates

Rapid temperature increases can cause the chemical reaction to occur too aggressively. The constant 60 °C environment prevents these spikes, ensuring the reaction proceeds at a manageable pace.

Eliminating Structural Cracking

By avoiding thermal shock and rapid heating, the oven prevents structural cracking. This is critical for maintaining the mechanical properties of the final block.

Developing Nanoporous Structures

The controlled environment facilitates the formation of a distinct nanoporous structure. This internal architecture is a key characteristic of properly cured geopolymers.

The Role of Reduced Pressure

While the primary reference emphasizes thermal control, the "vacuum" aspect of the oven provides specific advantages regarding pressure.

Lowering Boiling Points

The vacuum environment reduces the pressure inside the chamber. This lowers the boiling point of solvents, allowing them to evaporate efficiently at the prescribed 60 °C without requiring damaging high heat.

Preventing Surface Hardening

In atmospheric drying, the surface often dries and hardens first, trapping moisture inside. The vacuum environment prevents this surface hardening, ensuring the internal moisture can escape and the geopolymer cures uniformly from the inside out.

Understanding the Trade-offs

While the vacuum drying oven is highly effective, it requires adherence to specific limitations to avoid failure.

The Risk of Thermal Haste

Attempting to accelerate the process by exceeding 60 °C is a common pitfall. Higher temperatures often induce rapid expansion or reaction rates that the material cannot withstand, leading to immediate fracture or internal stress.

The Necessity of Time

The 24-hour cycle cannot be significantly shortened. Rushing the duration may result in an incomplete cure, leaving the center of the block soft or chemically unstable despite a hard outer shell.

Making the Right Choice for Your Goal

To ensure the success of your geopolymer fabrication, apply these conditions based on your specific requirements:

- If your primary focus is Structural Integrity: Adhere strictly to the 60 °C limit, as preventing rapid temperature increases is the single most important factor in stopping cracks.

- If your primary focus is Chemical Stability: Ensure the full 24-hour duration is met to allow the aluminosilicate network to fully polycondense and stabilize.

- If your primary focus is Mold Fidelity: Rely on the vacuum pressure to prevent surface skinning, ensuring the material remains uniform throughout the curing process.

By controlling heat and pressure simultaneously, you transform a volatile liquid resin into a durable, nanoporous solid.

Summary Table:

| Parameter | Requirement | Role in Geopolymer Curing |

|---|---|---|

| Temperature | Constant 60 °C | Accelerates polycondensation while preventing thermal cracking. |

| Curing Time | 24 Hours | Ensures uniform heat penetration and complete chemical transformation. |

| Pressure | Vacuum / Reduced | Lowers solvent boiling points and prevents premature surface hardening. |

| Final Structure | Nanoporous Solid | Creates a durable, high-strength aluminosilicate network. |

Elevate Your Materials Science with KINTEK Precision

Maximize the structural integrity of your geopolymers with our high-performance vacuum drying ovens. Backed by expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of laboratory research and industrial production.

Ready to achieve perfect mold fidelity and crack-free results? Contact our specialists today to find the ideal high-temperature solution for your unique needs.

Visual Guide

References

- Mukesh Kumar, Sudhanshu Sharma. Natural kaolin-derived ruthenium-supported nanoporous geopolymer: a sustainable catalyst for CO <sub>2</sub> methanation. DOI: 10.1039/d5cy00021a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does rapid quenching after diffusion treatment affect the material properties of the silicon structure? Lock-in Vital Phases

- How is a laboratory heat treatment furnace used for fluoride nanocrystal crystallization? Optimize Microstructure Control

- What role does a high-pressure reactor play in the production of hydrochar? Optimize Biomass Carbonization

- Why is a pressurized environment necessary for HMF synthesis? Ensure Liquid Phase Stability at High Temperatures

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is titanium used as a gettering agent in TiCo1-xCrxSb preparation? Achieve Purity in Your Alloy Synthesis

- Why is a constant temperature drying oven set to 60°C for 24 hours? Optimizing Sr4Al6O12SO4 Powder Quality

- What is the function of a planetary ball mill in magnesium production? Achieve Maximum Reaction Efficiency