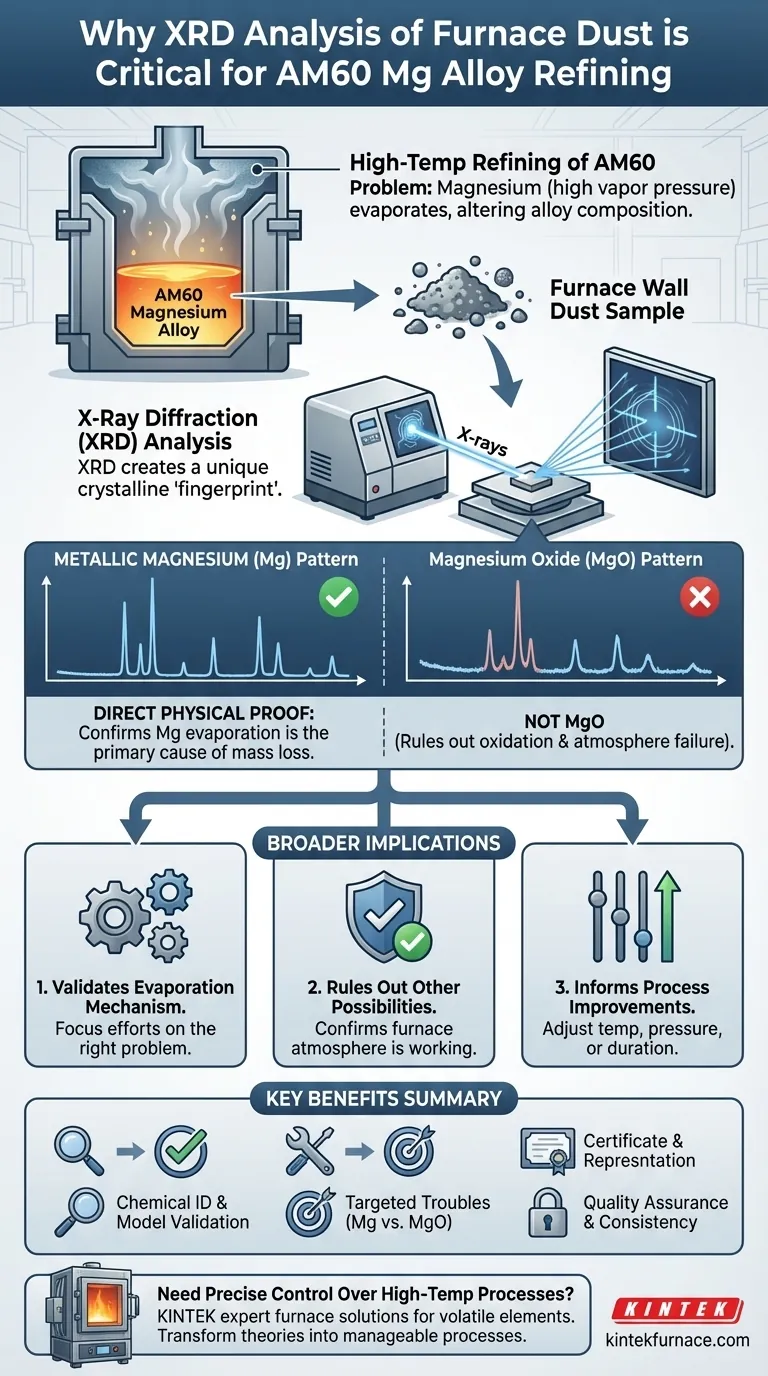

In short, the purpose of analyzing the dust from furnace walls with X-ray diffraction (XRD) is to chemically identify it. This analysis provides direct physical proof that metallic magnesium is the primary element that evaporates from the AM60 alloy during the high-temperature refining process, validating the scientific understanding of why mass is lost and the alloy's composition changes.

The core takeaway is that this analysis is not just a routine check; it is a critical investigative step to transform a theoretical understanding of material loss (magnesium evaporation) into a physically proven fact, which is essential for process control and quality assurance.

The Core Problem: Understanding Material Loss During Refining

High-temperature refining of magnesium alloys like AM60 is a necessary but volatile process. To understand the purpose of the XRD test, we must first understand the problem it helps solve.

The Challenge of High Vapor Pressure

Magnesium has a relatively high vapor pressure, meaning it has a strong tendency to turn from a liquid into a gas at high temperatures.

Other elements in the AM60 alloy, like aluminum, have a much lower vapor pressure and are less likely to evaporate under the same conditions.

This difference creates a significant challenge: during refining, you can lose a substantial amount of magnesium through evaporation, altering the final chemical composition of the alloy.

From Hypothesis to Evidence

Metallurgists can predict that magnesium loss is the likely cause of mass reduction based on chemical principles. However, a scientific or engineering process cannot rely on theory alone.

To control the process, you need physical evidence. The dust that condenses on the cooler furnace walls is the collected evidence of whatever material evaporated from the molten alloy.

XRD as the Definitive Investigative Tool

This is where X-ray diffraction becomes the crucial tool. It provides an unambiguous identification of the collected dust, moving from a well-founded hypothesis to a confirmed fact.

A Fingerprint for Crystalline Materials

Think of XRD as a technique that creates a unique fingerprint for any crystalline substance.

When an X-ray beam hits a material, it diffracts into a specific pattern based on the arrangement of atoms in its crystal structure. No two different crystalline materials produce the same pattern.

The Decisive Result

By running an XRD analysis on the furnace dust, its diffraction pattern can be compared against a database of known materials.

The analysis in this case revealed the pattern for pure, metallic magnesium. This is direct, incontrovertible proof that the substance leaving the molten alloy was magnesium, not aluminum or another compound.

The Broader Implications of the Analysis

Confirming the identity of the dust has significant consequences for process control and quality assurance. This simple test validates the entire model of what is happening inside the furnace.

Validating the Evaporation Mechanism

The most immediate result is the validation of the evaporation mechanism. It confirms that the primary source of mass loss and compositional change is the boiling off of magnesium, empowering engineers to focus their efforts on solving the right problem.

Ruling Out Other Possibilities

The XRD result is just as important for what it didn't find.

If the dust had been identified as Magnesium Oxide (MgO), it would imply that the furnace's protective atmosphere had failed and the magnesium was burning off. Finding metallic magnesium confirms the atmosphere was likely working as intended, and the issue is purely one of evaporation due to heat.

Informing Process Improvements

Knowing for certain that magnesium evaporation is the issue allows engineers to develop targeted solutions. These can include lowering the refining temperature, increasing the pressure inside the furnace, or refining for a shorter duration to minimize the loss and maintain the desired alloy composition.

Making the Right Decision for Your Process

The application of this analysis provides clear, actionable insights depending on your primary objective.

- If your primary focus is process validation: Use XRD on furnace byproducts to gain definitive physical proof that confirms your theoretical models of material behavior.

- If your primary focus is quality control: Identifying the precise mechanism of compositional change is the first step to controlling it and ensuring your final alloy consistently meets its specifications.

- If your primary focus is troubleshooting: This analysis can quickly determine if material loss is due to simple evaporation (metallic Mg) or a more serious process failure like oxidation (MgO).

Ultimately, analyzing this dust transforms a complex chemical theory into a tangible engineering problem that can be measured, managed, and solved.

Summary Table:

| Purpose of XRD Analysis | Key Insight | Impact on Process |

|---|---|---|

| Chemical Identification | Confirms metallic magnesium is the primary evaporating element | Validates theoretical models of mass loss |

| Mechanism Validation | Distinguishes between evaporation (Mg) and oxidation (MgO) | Enables targeted troubleshooting and atmosphere control |

| Quality Assurance | Provides direct evidence for compositional changes | Supports consistent alloy specification compliance |

| Process Improvement | Informs adjustments to temperature, pressure, and duration | Minimizes magnesium loss and optimizes refining efficiency |

Need Precise Control Over Your High-Temperature Processes?

This analysis demonstrates the critical link between material behavior and process parameters. For processes involving volatile elements like magnesium, precise thermal control is non-negotiable.

KINTEK's expertise can help you achieve this level of control. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all customizable for your unique high-temperature applications—whether you're refining specialty alloys, conducting heat treatment, or developing advanced materials.

Let us help you transform complex material theories into manageable, high-yield processes.

Contact our thermal engineering experts today to discuss how a KINTEK solution can enhance your process validation, quality control, and troubleshooting capabilities.

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules