At its core, a rotary tube furnace is a cylindrical processing chamber that combines rotation with a slight incline to continuously heat, mix, and transport materials. Its basic construction centers around four key systems: a structural body, an insulating refractory lining, a mechanical drive for rotation, and a precisely controlled heat source.

The essential design principle of a rotary tube furnace is to use controlled motion—rotation for mixing and inclination for transport—to ensure every particle of the material receives a uniform thermal treatment as it moves continuously through the furnace.

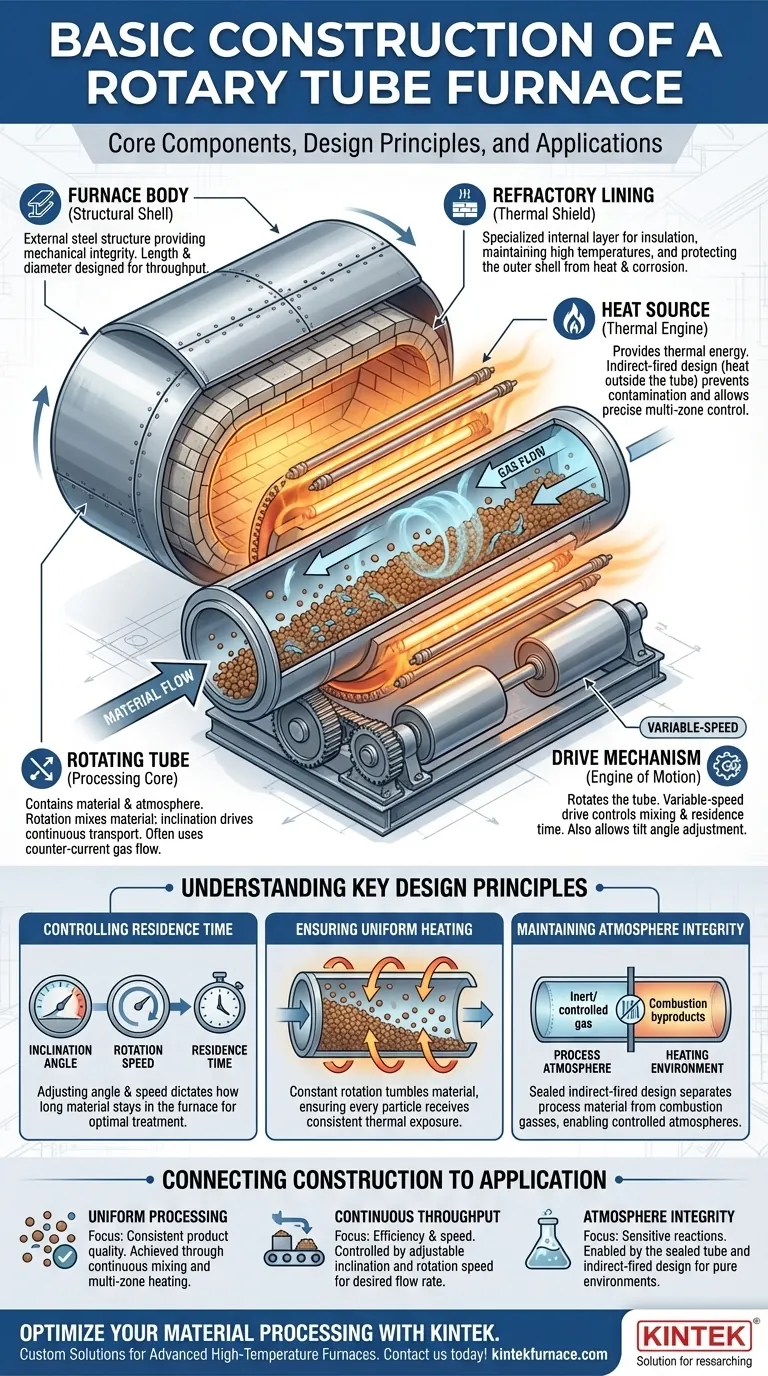

Deconstructing the Rotary Tube Furnace: Core Components

A rotary tube furnace is an integrated system where each component serves a distinct and critical purpose. Understanding how these parts function together is key to appreciating the furnace's capabilities.

The Furnace Body (The Structural Shell)

The furnace body is the external steel structure, typically a long, welded cylindrical barrel. It provides the mechanical integrity and support for the entire apparatus.

The length and diameter of this body are not arbitrary; they are specifically designed based on the required throughput and the residence time needed for the material being processed.

The Refractory Lining (The Thermal Shield)

Inside the steel body is a crucial layer of refractory material. This lining can be made of specialized bricks, castable cement, or other moldable, high-temperature substances.

This lining serves two primary functions: it insulates the furnace to maintain extremely high internal temperatures and protects the outer steel shell from thermal stress and chemical corrosion.

The Drive Mechanism (The Engine of Motion)

The drive mechanism is the mechanical system responsible for the furnace's signature rotation. It typically consists of a large drive gear or a system of driven rollers that turn the entire tube.

Most modern designs feature a variable-speed drive. This allows operators to precisely adjust the rotation speed, which directly controls the degree of mixing and the time the material spends in the heat zone. The mechanism often allows for adjusting the tilt or inclination angle as well.

The Heat Source (The Thermal Engine)

The heat source provides the energy for the thermal process and can be either electric or gas-fired. A key design feature is that these furnaces are often indirect-fired.

In an indirect-fired design, the heat is applied to the outside of the rotating tube that contains the material. This prevents contamination from combustion byproducts and allows for multiple thermal control zones along the tube's length, enabling a precise temperature profile for sophisticated processes.

The Rotating Tube (The Processing Core)

The central element is the tube that contains the process material and atmosphere. As the furnace rotates, the material inside is constantly tumbled and mixed, preventing hot spots and ensuring uniformity.

The slight inclination of the tube causes the material to gradually move from the higher entry point to the lower exit point, creating a continuous processing flow. Often, hot gases are passed through the tube in the opposite direction of the material flow (counter-current flow) to maximize heat transfer efficiency.

Understanding Key Design Principles

The construction of a rotary tube furnace is a direct reflection of the physical principles it leverages. The interplay between its components dictates its performance and application.

Controlling Residence Time

The combination of inclination angle and rotation speed gives the operator direct control over the residence time—how long the material stays inside the furnace.

A steeper angle or faster rotation decreases residence time for high-throughput applications. A shallower angle or slower rotation increases residence time, which is critical for processes requiring prolonged heat exposure.

Ensuring Uniform Heating

Constant rotation is the furnace's mechanism for achieving exceptional temperature uniformity. By continuously tumbling the material, every particle is exposed to the heat source evenly, which is essential for consistent product quality.

Maintaining Atmosphere Integrity

In an indirect-fired system, the sealed rotating tube separates the process material from the external heating environment. This allows for precise control of the internal atmosphere, enabling processes that require inert (nitrogen, argon), oxidizing, or reducing environments without risk of contamination.

Connecting Construction to Application

Understanding how the furnace is built allows you to see how its design directly enables specific processing goals.

- If your primary focus is uniform processing: The constant mixing from rotation, combined with multiple, independent heating zones, ensures every particle follows a highly consistent thermal path.

- If your primary focus is continuous throughput: The adjustable inclination angle and variable rotation speed are your primary tools for controlling how quickly and efficiently material is processed.

- If your primary focus is atmosphere integrity: The sealed process tube in an indirect-fired design is the critical feature that allows for pure, controlled atmospheres during sensitive chemical reactions or treatments.

By grasping these fundamental construction elements, you can effectively evaluate how a rotary tube furnace will meet your specific material processing objectives.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Body | Provides structural support and integrity | Cylindrical steel barrel, designed for throughput and residence time |

| Refractory Lining | Insulates and protects from high temperatures | Made of bricks or castable cement, prevents thermal stress and corrosion |

| Drive Mechanism | Enables rotation and inclination | Variable-speed drive, adjustable tilt for mixing and transport control |

| Heat Source | Supplies thermal energy for processing | Electric or gas-fired, indirect-fired design for contamination-free heating |

| Rotating Tube | Contains and processes materials | Allows tumbling and mixing, counter-current flow for efficiency |

Ready to optimize your material processing with a custom rotary tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating