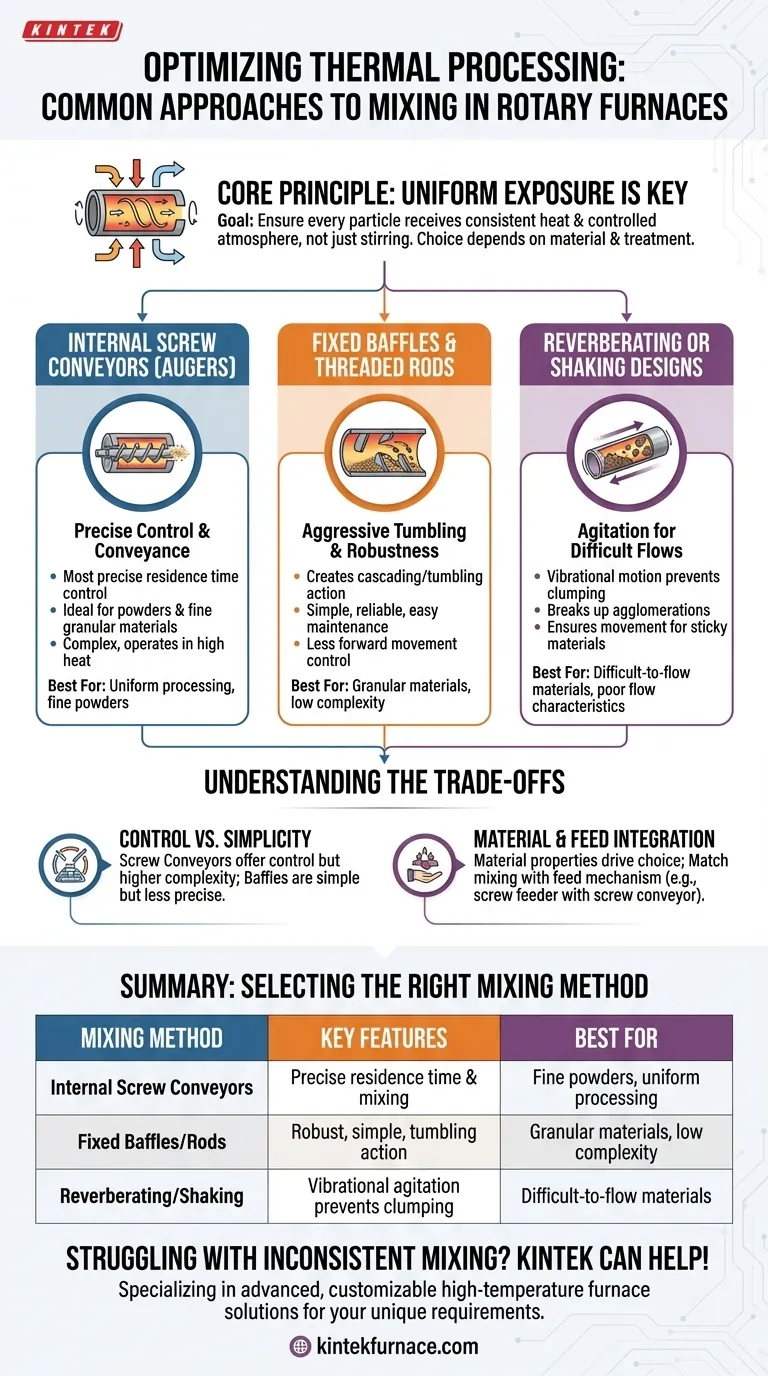

At its core, mixing in a rotary furnace is achieved by using mechanical internals or specific motion to agitate the material as it moves through the heated tube. The most common methods are internal screw conveyors (augers) for precise control, fixed baffles or threaded rods that cause material to tumble, and reverberating designs that shake the material to promote mixing.

The primary goal of mixing is not simply to stir material, but to ensure every particle receives uniform exposure to both heat and the controlled processing atmosphere. The choice of mixing method is therefore a critical decision dictated by your material's properties and the specific thermal treatment you need to achieve.

The Purpose of Active Mixing

A rotary furnace's basic rotation provides a baseline level of mixing as material tumbles. However, for many industrial processes, this is insufficient to guarantee a uniform product.

Overcoming Inconsistent Heat Treatment

Without active mixing, material can travel through the furnace with a cool, unexposed core and an overheated outer layer. Effective mixing continuously circulates the material, exposing new surfaces to the furnace wall and ensuring consistent, homogenous heating.

Ensuring Uniform Gas-Solid Interaction

Many processes use specific atmospheres, such as inert gases (nitrogen, argon) to prevent oxidation or reactive gases (hydrogen) to induce chemical changes. Mixing is critical for ensuring every particle of the material comes into contact with this processing gas, driving complete and efficient reactions.

Common Mechanical Mixing Mechanisms

To enhance the natural tumbling action, several mechanical designs are employed inside the furnace tube.

Internal Screw Conveyors or Augers

An internal screw, or auger, runs the length of the furnace tube. As it rotates, it simultaneously mixes the material and conveys it forward at a highly controlled rate.

This method offers the most precise control over residence time—the duration the material spends in the heated zone. It is ideal for powders and fine granular materials that require very uniform processing.

Fixed Baffles and Threaded Rods

A simpler approach involves welding baffles, fins, or threaded rods to the furnace's inner wall. As the furnace tube rotates, these fixed internals lift and drop the material, creating a cascading or tumbling effect.

This method promotes aggressive mixing and is robust and easy to maintain. It is well-suited for granular materials that do not require the precise conveyance control of a screw.

Reverberating or Shaking Designs

In this configuration, the furnace tube is subjected to a vibrational or shaking motion in addition to, or instead of, simple rotation.

This technique is particularly effective for promoting mixing in materials that might otherwise clump, stick, or have poor flow characteristics. The vibration agitates the bed of material, breaking up agglomerations and ensuring movement.

Understanding the Trade-offs

No single mixing method is universally superior. The correct choice involves balancing process control with operational complexity and the nature of your material.

Control vs. Simplicity

An internal screw conveyor offers maximum control over residence time and mixing, but it is a complex mechanical system that operates in an extreme-temperature environment, adding to maintenance requirements.

Fixed baffles are exceptionally simple and reliable. However, they offer less control over the material's forward movement, which becomes primarily dependent on the furnace's angle of inclination and rotation speed.

Impact of Material Characteristics

The properties of the material being processed are a primary driver of your choice.

Fine, free-flowing powders are often best handled with a screw conveyor to prevent uncontrolled fluidization and ensure consistent dosing. Materials with irregular particle sizes or those that are less free-flowing may benefit from the more aggressive tumbling action of baffles.

Feed Mechanism Integration

The mixing mechanism must work in concert with the feeding mechanism. A screw feeder dosing material into the furnace pairs logically with an internal screw for continuous, controlled processing. A vibratory hopper might be used to feed a furnace that relies on baffles for mixing.

Making the Right Choice for Your Process

Your selection should be a direct reflection of your material's needs and your processing goals.

- If your primary focus is maximum control and uniformity: An internal screw conveyor is the superior choice, especially for fine powders or reactions requiring precise residence time.

- If your primary focus is simplicity and robustness: Fixed internal baffles or threaded rods provide excellent mixing for many granular materials with lower operational complexity.

- If your primary focus is processing difficult-to-flow materials: A reverberating or shaking design can provide the necessary agitation to ensure material moves and mixes effectively.

Ultimately, selecting the right mixing strategy is fundamental to achieving consistent, high-quality results from your thermal processing operation.

Summary Table:

| Mixing Method | Key Features | Best For |

|---|---|---|

| Internal Screw Conveyors | Precise control of residence time and mixing | Fine powders, uniform processing |

| Fixed Baffles and Threaded Rods | Robust, simple design with tumbling action | Granular materials, low complexity |

| Reverberating or Shaking Designs | Vibrational agitation to prevent clumping | Difficult-to-flow materials, poor flow characteristics |

Struggling with inconsistent mixing in your thermal processes? KINTEK specializes in advanced high-temperature furnace solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we offer products like Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise matching to your unique experimental requirements, enhancing uniformity and efficiency. Contact us today to discuss how we can optimize your lab's performance!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity