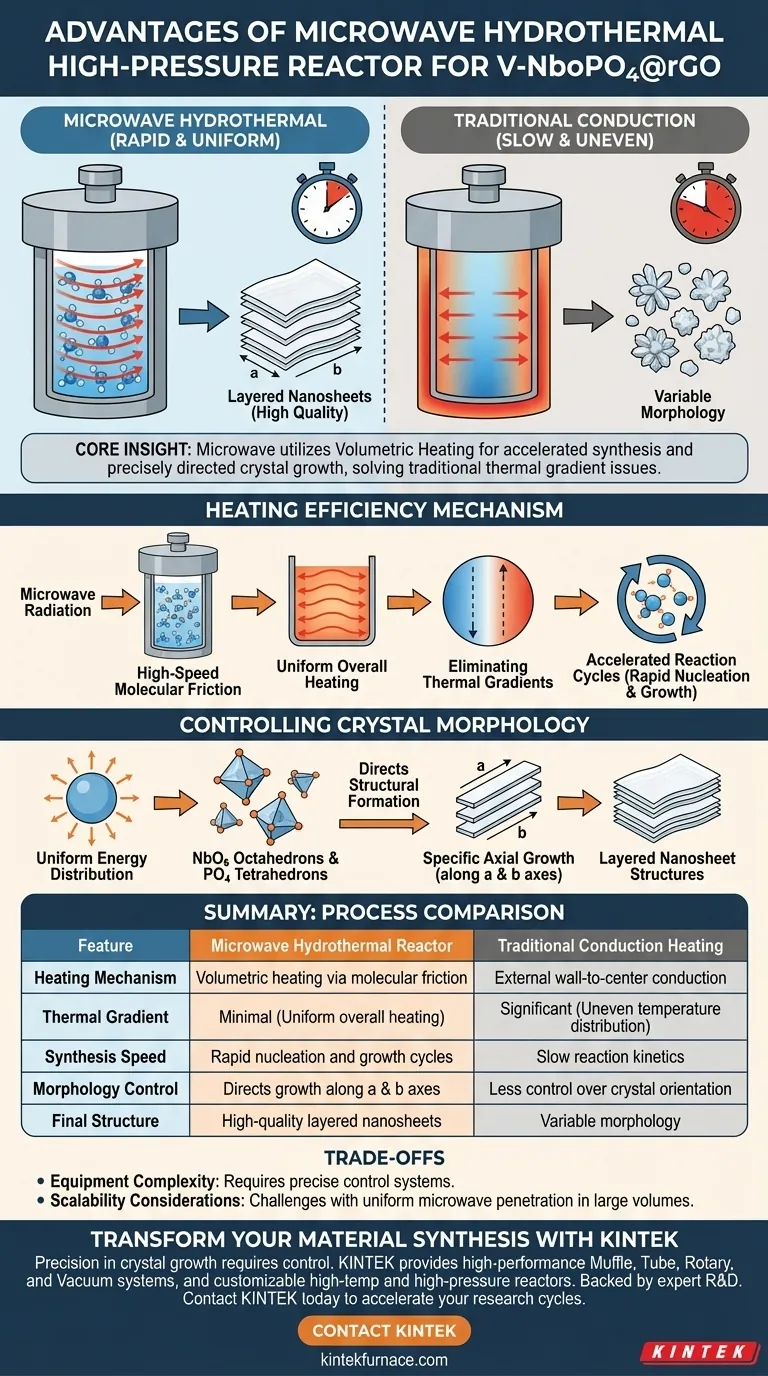

The primary process advantage of using a microwave hydrothermal high-pressure reactor is its ability to generate rapid, uniform internal heat through high-speed molecular friction. Unlike traditional methods, this technique significantly accelerates the nucleation and growth cycles of the material while precisely directing crystal growth to form high-quality layered nanosheet structures.

Core Insight: Traditional conduction heating often suffers from thermal gradients and slower reaction kinetics. Microwave hydrothermal synthesis solves this by utilizing volumetric heating, which drastically shortens synthesis time and aligns crystal growth along specific axes to ensure superior morphological quality.

The Mechanism of Heating Efficiency

Rapid Internal Heating

The fundamental advantage of this reactor type is how it delivers energy. It utilizes microwave radiation to induce high-speed friction among the reaction liquid molecules.

Eliminating Thermal Gradients

This molecular friction results in uniform overall heating throughout the vessel. This contrasts sharply with traditional conduction heating, which relies on heat transferring slowly from the outside walls inward.

Accelerating Reaction Cycles

The efficiency of this uniform energy distribution has a direct impact on time. It significantly shortens the cycles required for both nucleation (the birth of crystals) and their subsequent growth.

Controlling Crystal Morphology

Directing Structural Formation

Beyond speed, the microwave process influences the physical geometry of the NbOPO4. The uniform energy distribution guides the growth of NbO6 octahedrons and PO4 tetrahedrons.

Specific Axial Growth

The process specifically promotes growth along the $a$ and $b$ axes. This directional control is critical for defining the final shape of the material.

Formation of Layered Nanosheets

By guiding the crystal growth along these specific axes, the reactor facilitates the formation of high-quality layered nanosheet structures. This morphology is often difficult to achieve with the uneven energy distribution of conventional heating.

Understanding the Trade-offs

Equipment Complexity

While the process yields superior materials, microwave high-pressure reactors are generally more complex than standard hydrothermal autoclaves. They require precise control systems to manage the interaction between microwave radiation and pressure.

Scalability Considerations

Uniform microwave penetration can become challenging as the reactor volume increases. While excellent for laboratory and pilot-scale synthesis of high-quality nanosheets, scaling up to industrial bulk production requires specialized engineering to maintain the same heating uniformity.

How to Apply This to Your Project

If your primary focus is Morphology Control:

- Choose this method to ensure the formation of layered nanosheets by forcing crystal growth along the $a$ and $b$ axes.

If your primary focus is Process Efficiency:

- Utilize this reactor to drastically reduce production time by shortening nucleation and growth cycles through volumetric heating.

By leveraging the high-speed molecular friction of microwave synthesis, you move beyond simple heating to active structural engineering of your composites.

Summary Table:

| Feature | Microwave Hydrothermal Reactor | Traditional Conduction Heating |

|---|---|---|

| Heating Mechanism | Volumetric heating via molecular friction | External wall-to-center conduction |

| Thermal Gradient | Minimal (Uniform overall heating) | Significant (Uneven temperature distribution) |

| Synthesis Speed | Rapid nucleation and growth cycles | Slow reaction kinetics |

| Morphology Control | Directs growth along $a$ and $b$ axes | Less control over crystal orientation |

| Final Structure | High-quality layered nanosheets | Variable morphology |

Transform Your Material Synthesis with KINTEK

Precision in crystal growth requires more than just heat—it requires control. Backed by expert R&D and manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, and Vacuum systems, alongside customizable high-temp and high-pressure reactors tailored for advanced material synthesis like V-NbOPO4@rGO.

Whether you are scaling from lab to pilot or refining morphology control, our team delivers the engineering expertise you need. Contact KINTEK today to discuss your unique project requirements and discover how our advanced laboratory solutions can accelerate your research cycles.

Visual Guide

References

- Zhongteng Chen, Zhipeng Sun. Tuning the Electronic Structure of Niobium Oxyphosphate/Reduced Graphene Oxide Composites by Vanadium‐Doping for High‐Performance Na<sup>+</sup> Storage Application. DOI: 10.1002/cnl2.70010

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What experimental conditions do physical property measurement systems provide for TaAs2? Explore Cryogenic Transport

- Why is high-temperature drying of NaCl particles necessary? Prevent Aluminum Foam Defects and Ensure Integrity

- What is the objective of coordinating mechanical stirring and heating for perovskite slurries? Achieve Homogeneity

- Why is 800 °C necessary for NCNTs? Unlock Superior Conductivity and Ion Transport

- What is the function of a high-pressure hydrothermal reactor in hydrochar synthesis? Unlock Biomass Transformation

- Why is preheating a metal mold to 660 °C necessary for Al/Cu bimetallic composites? Unlock Strong Chemical Bonding

- Why is a two-step process used for waste bone-derived carbon? Unlock Ultra-High Surface Area & Stability

- What are the advantages of Spark Plasma Sintering (SPS)? Enhance Thermoelectric Performance in Copper Sulfide