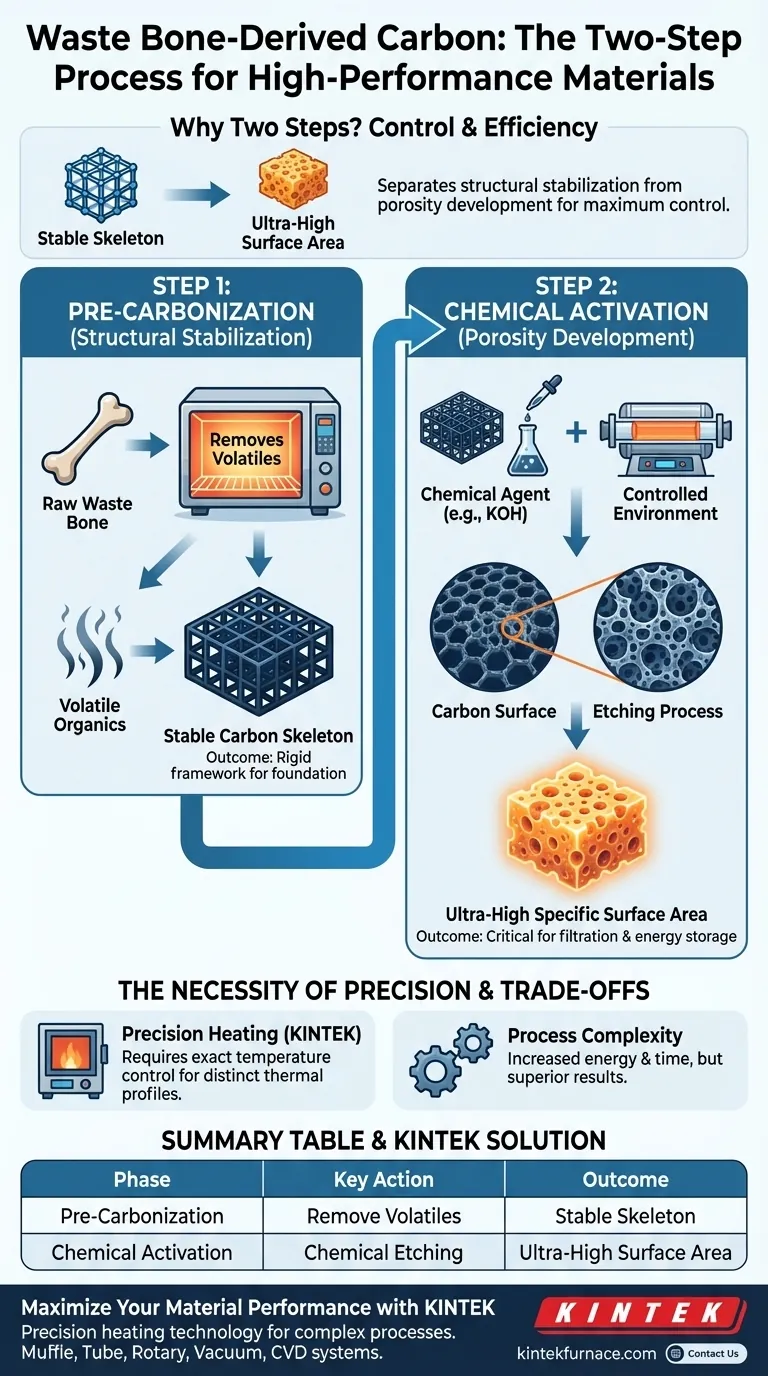

The two-step process is essential for separating structural stabilization from porosity development. By first pre-carbonizing the material, you ensure the removal of volatile organics to create a stable framework. This prepares the waste bone for a subsequent activation step, which specifically targets surface area expansion without compromising the material's foundational integrity.

The primary advantage of this sequential approach is control. It allows you to lock in a stable carbon skeleton first, ensuring that the subsequent chemical etching can generate an ultra-high specific surface area with maximum efficiency.

The Function of Pre-Carbonization

Eliminating Volatile Components

The initial phase of the process focuses on purification. Heating the raw waste bone drives off volatile organic compounds that are naturally present in the biomass. Removing these elements early prevents them from interfering with the chemical reactions required in the later stages.

Establishing a Stable Skeleton

Once the volatiles are removed, the remaining material forms a stable carbon skeleton. This rigid framework serves as the physical foundation for the final product. Without this stabilization, the material could collapse or degrade unpredictably during the more aggressive activation phase.

The Role of Chemical Activation

Etching the Carbon Surface

The second step typically involves introducing a chemical agent, such as KOH (potassium hydroxide). This step is performed in a controlled environment, such as a tube furnace. The chemical agent actively etches the previously stabilized carbon surface.

Generating Ultra-High Surface Area

The physical etching process drastically alters the material's topography. By eating away specific parts of the carbon skeleton, the process generates an ultra-high specific surface area. This high surface area is the critical performance metric for activated carbon used in filtration or energy storage.

The Necessity of Precision

Leveraging Temperature Control

Success in this two-step process relies on the precise capabilities of laboratory high-temperature furnaces. Distinct thermal profiles are required for driving off volatiles versus activating the carbon. Separating the steps allows for the exact temperature control needed to optimize the chemical reactions in each phase.

Understanding the Trade-offs

Process Complexity and Energy

While this method produces superior materials, it is inherently more complex than single-step carbonization. It requires two distinct heating cycles, which increases energy consumption and total processing time.

Chemical Handling Requirements

The use of chemical activators like KOH introduces handling challenges. These agents are corrosive and require careful management within the furnace environment to prevent equipment damage or safety hazards.

Optimizing Your Material Preparation

To ensure you are getting the most out of your waste bone-derived carbon, consider your specific performance targets when designing your thermal profile.

- If your primary focus is Structural Integrity: Ensure your pre-carbonization dwell time is sufficient to fully remove volatiles and solidify the carbon skeleton before introducing chemical agents.

- If your primary focus is Maximum Surface Area: Prioritize precise temperature regulation during the KOH activation phase to maximize the etching effect without destroying the underlying framework.

This sequential method offers the most reliable path for converting biological waste into high-performance functional materials.

Summary Table:

| Process Phase | Primary Objective | Key Action | Outcome |

|---|---|---|---|

| Pre-Carbonization | Structural Stabilization | Removal of volatile organic compounds | Stable carbon skeleton framework |

| Chemical Activation | Porosity Development | Chemical etching (e.g., with KOH) | Ultra-high specific surface area |

| Precision Control | Optimization | Distinct thermal profile management | Maximum efficiency and material integrity |

Maximize Your Material Performance with KINTEK

Ready to transform biological waste into high-performance functional materials? KINTEK provides the precision heating technology required for complex two-step carbonization and activation processes.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory needs. Whether you require exact temperature control for structural stabilization or a robust environment for chemical etching, our equipment ensures consistent, high-quality results for your research and production.

Take the next step in material excellence—Contact KINTEK today for a customized solution!

Visual Guide

References

- Perseverance Dzikunu, Pedro Vilaça. Waste-to-carbon-based supercapacitors for renewable energy storage: progress and future perspectives. DOI: 10.1007/s40243-024-00285-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of high-temperature calcination equipment in Waste Tire Charcoal preparation? Master WTC Pyrolysis

- What is the purpose of an industrial oven for powder pre-treatment? Ensure Accurate Silica Analysis

- What is the primary role of a vacuum drying oven in WO3 nanostructure preparation? Achieve Perfect Morphology

- What is an industrial oven and which industries use it? Discover Versatile Thermal Processing Solutions

- Why Use a Heating Sample Stage for Si/SiO2 Interface Study? Analyze Thermal Stress & CTE Mismatch Real-Time

- What is the technical value of a Hydrogen Reduction-type Test Furnace in green steelmaking? Scale Sustainable Production

- How are high-temperature furnaces and precision balances used for alloy oxidation kinetics? Expert Analysis

- What is the function of a vacuum drying oven in the post-treatment of PPy/alpha-Fe2O3 composite materials? Expert Insights