A sample stage with heating capabilities is required to accurately simulate the thermal stress environments that devices encounter during actual service. This equipment allows researchers to bridge the gap between static material analysis and the dynamic physical realities of operating conditions.

The primary driver for using a heating stage is the mismatch in Coefficient of Thermal Expansion (CTE) between Silicon and Silicon Dioxide. Heating allows for the direct, real-time observation of how this mismatch drives atomic migration and crack propagation, which is vital for high-stakes reliability engineering.

The Mechanics of Thermal Stress

Exposing the CTE Mismatch

Silicon (Si) and Silicon Dioxide (SiO2) expand at different rates when exposed to heat. This difference is known as a mismatch in the Coefficient of Thermal Expansion (CTE).

At room temperature, these materials may appear stable. However, as temperature rises, the differing expansion rates generate significant internal stress at the interface where the two materials meet.

Replicating Service Environments

Devices often operate in environments with fluctuating temperatures, particularly in aerospace applications.

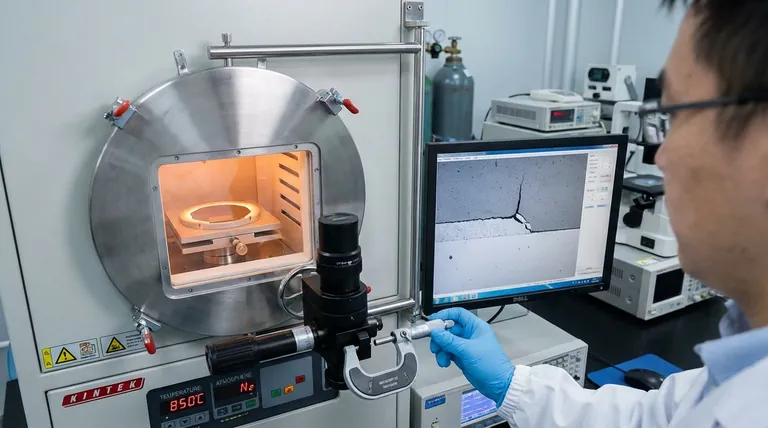

A standard microscope stage cannot replicate these conditions. An in-situ heating stage or high-temperature furnace system is necessary to mimic the specific thermal loads the device will face during its service life.

Real-Time Observation of Failure

Monitoring Physical Deformation

Static "before and after" images are often insufficient for understanding failure.

With a heating stage, researchers can perform real-time observations. This allows them to record exactly when and how physical deformation begins as the temperature climbs.

Tracking Crack Propagation

One of the most critical failure modes in Si/SiO2 interfaces is cracking.

Heating stages allow scientists to watch crack propagation as it happens. By correlating the temperature with the growth of the crack, researchers can pinpoint the exact thermal thresholds that endanger device integrity.

Observing Atomic Migration

Thermal stress does not just cause macroscopic cracks; it affects material at the atomic level.

High temperatures can trigger atomic migration, where atoms move and rearrange within the lattice. This process alters the electronic and mechanical properties of the device, often leading to instability.

Understanding the Operational Trade-offs

The Necessity of Precision

While heating stages provide critical data, they introduce significant complexity to the testing process.

The validity of the data relies entirely on precisely controlling the temperature. Inaccurate thermal regulation can lead to misleading data regarding the material's failure points.

Simulation vs. Reality

An in-situ stage simulates the thermal environment, but it is a controlled approximation.

Researchers must carefully calibrate the heating profile to ensure it reflects the actual service environment (e.g., rapid thermal cycling in aerospace) rather than just a steady increase in heat.

Making the Right Choice for Your Goal

To determine if a heating stage is necessary for your specific project, consider the following:

- If your primary focus is basic structural analysis: A standard ambient-temperature stage is sufficient for observing geometry and static defects.

- If your primary focus is reliability in extreme environments: A heating stage is mandatory to observe stress-induced failures caused by CTE mismatch.

For applications where device stability is non-negotiable, understanding the dynamic thermal behavior of the Si/SiO2 interface is the only way to ensure long-term performance.

Summary Table:

| Feature | Impact on Si/SiO2 Interface | Research Benefit |

|---|---|---|

| CTE Mismatch | Generates internal stress between layers | Identifies structural weak points |

| Thermal Cycling | Triggers atomic migration & deformation | Replicates real-world service life |

| In-Situ Heating | Enables real-time crack propagation tracking | Pinpoints exact failure thresholds |

| Precision Control | Ensures repeatable thermal profiles | Increases reliability of data analysis |

Elevate Your Interface Research with KINTEK

Don't let static analysis limit your understanding of material failure. KINTEK’s high-precision heating systems allow you to simulate extreme service environments with unparalleled accuracy.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temp furnaces—all fully customizable to your specific research needs.

Ready to bridge the gap between simulation and reality? Contact our engineering team today to find the perfect thermal solution for your Si/SiO2 reliability testing.

References

- W. Zhang, Yintang Yang. Research on Si/SiO2 Interfaces Characteristics Under Service Conditions. DOI: 10.3390/sym17010046

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is an in-situ XRD system with a high-temperature furnace necessary for Y-W-N ceramics? Capture Real-Time Stability

- What is the objective of placing TC4 titanium alloy parts on asbestos pads? Control Stress and Thermal Shock

- What is the role of calcination using high-temperature furnaces in the top-down synthesis of ZnO-NPs?

- What is the primary function of the low-temperature pyrolysis process? Ensure Safe Battery Recycling with Pretreatment

- Why is it necessary to grind iron concentrate to 5-10 microns? Optimize Your Iron Ore Reduction Kinetics

- How does a cooling circulation unit assist in plastic pyrolysis? Optimize Bio-Oil & Gas Separation

- What is the significance of high-precision temperature monitoring systems in SPS? Control Ti-6Al-4V/HA Microstructure

- What is the role of a Pulsed Laser Deposition (PLD) system in orthopyroxene Fe-Mg experiments? Precision Film Growth