In top-down synthesis, the primary role of calcination is to thermally treat solid bulk zinc oxide to significantly increase its brittleness. By subjecting the material to controlled heat in a high-temperature or muffle furnace, you alter its mechanical properties, making it far more susceptible to fracture and fragmentation during subsequent crushing or milling stages.

Core Takeaway The furnace acts as a mechanical preparatory tool rather than a chemical reactor in this specific context. Its function is to weaken the bulk material's structural integrity to facilitate grinding, but this requires strict temperature ceilings (<400°C) to prevent the counter-productive fusion of grains.

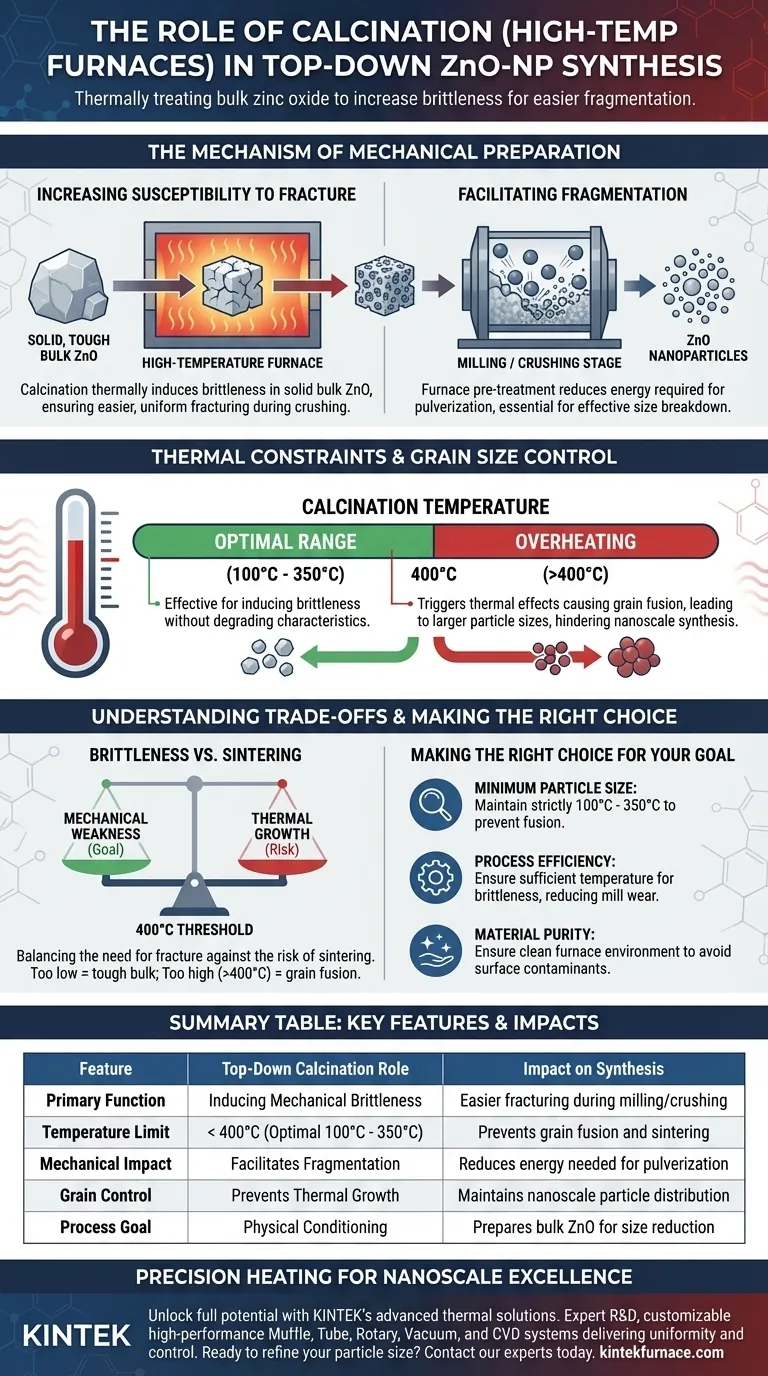

The Mechanism of Mechanical Preparation

Increasing Susceptibility to Fracture

The top-down approach relies on physically breaking down large particles into nanoscale units.

Calcination is employed here to thermally induce brittleness in the solid bulk zinc oxide.

This structural weakening ensures that when the material enters the crushing or grinding phase, it fractures more easily and uniformily, rather than deforming or resisting the mechanical force.

Facilitating Fragmentation

The efficiency of the top-down method is directly tied to how easily the bulk material can be pulverized.

By pre-treating the zinc oxide in a furnace, you reduce the energy required for the fragmentation process.

This preparation step is essential for achieving the necessary breakdown during high-energy ball milling or similar crushing techniques.

Thermal Constraints and Grain Size Control

The 400°C Threshold

While heat is necessary to induce brittleness, the specific temperature applied is the critical variable for quality control.

Research indicates that the calcination temperature must be maintained below 400°C.

Operating at lower temperatures, such as 100°C or 350°C, has been proven effective for preparing the material without degrading the final particle characteristics.

Preventing Grain Fusion

There is a distinct thermal ceiling where the benefits of calcination reverse.

Higher temperatures trigger thermal effects that cause tiny grains to fuse together.

This fusion results in larger grain sizes, which directly contradicts the objective of synthesizing nano-scale particles.

Understanding the Trade-offs

Brittleness vs. Sintering

The central challenge in this process is balancing the need for mechanical weakness against the risk of thermal growth.

If the temperature is too low, the bulk zinc oxide may remain too tough, leading to inefficient crushing and larger final particles.

If the temperature is too high (exceeding 400°C), the grains sinter (fuse), rendering the subsequent crushing steps less effective at producing true nanoparticles.

Methodological Distinction

It is vital to distinguish this top-down application from bottom-up chemical synthesis.

In bottom-up methods, furnaces are used to remove organic precursors or induce crystallization at high temperatures.

In this top-down context, the furnace is strictly for physical conditioning; applying the high-heat logic of bottom-up synthesis here will ruin the particle size distribution.

Making the Right Choice for Your Goal

When configuring your furnace parameters for top-down ZnO synthesis, consider the following:

- If your primary focus is Minimum Particle Size: Maintain calcination temperatures strictly between 100°C and 350°C to prevent any grain fusion.

- If your primary focus is Process Efficiency: Ensure the temperature is sufficient to induce brittleness, preventing excessive wear on your milling equipment during the crushing phase.

- If your primary focus is Material Purity: While top-down relies on bulk crushing, ensure the furnace environment is clean to avoid introducing surface contaminants during the heating phase.

Success in top-down synthesis relies on using heat to weaken the material without allowing thermal energy to rebuild the grains you are trying to break.

Summary Table:

| Feature | Top-Down Calcination Role | Impact on Synthesis |

|---|---|---|

| Primary Function | Inducing Mechanical Brittleness | Easier fracturing during milling/crushing |

| Temperature Limit | < 400°C (Optimal 100°C - 350°C) | Prevents grain fusion and sintering |

| Mechanical Impact | Facilitates Fragmentation | Reduces energy needed for pulverization |

| Grain Control | Prevents Thermal Growth | Maintains nanoscale particle distribution |

| Process Goal | Physical Conditioning | Prepares bulk ZnO for size reduction |

Precision Heating for Nanoscale Excellence

Unlock the full potential of your top-down synthesis with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific temperature thresholds and material requirements. Whether you are inducing brittleness in ZnO or optimizing crystallization, our lab high-temperature furnaces deliver the uniformity and control your research demands.

Ready to refine your particle size? Contact our experts today to find the perfect furnace for your laboratory needs.

Visual Guide

References

- Ahmad Wafi Mahmood Zuhdi, Vallerina Armetha. Fabrication of ZnO Nanoparticles Using the Top‐Down Method and Its Effect on the Rheological Properties of Gelatin‐Based Bionanocomposite Solutions and Films. DOI: 10.1002/fbe2.70020

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is MgO used as a hard template for waste PET to carbon conversion? Unlock 3D Porous Structures

- How does the post-rolling annealing process improve the interfacial microstructure? Enhancing Titanium-Steel Bond Strength

- What is the significance of using a hydrogen etching process in a reaction chamber? Mastering SiC Surface Preparation

- How do quartz-capped vials facilitate the pyrolysis of magnetic chitosan carbon? Master Localized Reducing Atmospheres

- What pre-treatment procedures are required for a Stainless Steel Reactor? Maximize Metal Hydride Reaction Success

- What are the advantages of using electron bombardment heating systems for Niobium? Achieve Industrial Fidelity

- How do chill rings specifically influence the temperature field distribution? Expert Insight into Crystal Casting

- What key data does a Simultaneous Thermal Analyzer (STA) provide for lignite combustion? Assess Fire Risk with Precision