A Simultaneous Thermal Analyzer (STA) provides a comprehensive profile of lignite combustion by concurrently recording mass changes and heat flow variations during a controlled heating process. This dual-stream data allows for the precise identification of critical temperature thresholds and the calculation of activation energy, which serves as a direct indicator of re-ignition risk.

By integrating mass loss data with heat flow measurements, STA transforms abstract thermal reactions into quantifiable safety metrics, specifically pinpointing the temperature thresholds where stable coal transitions into a combustion hazard.

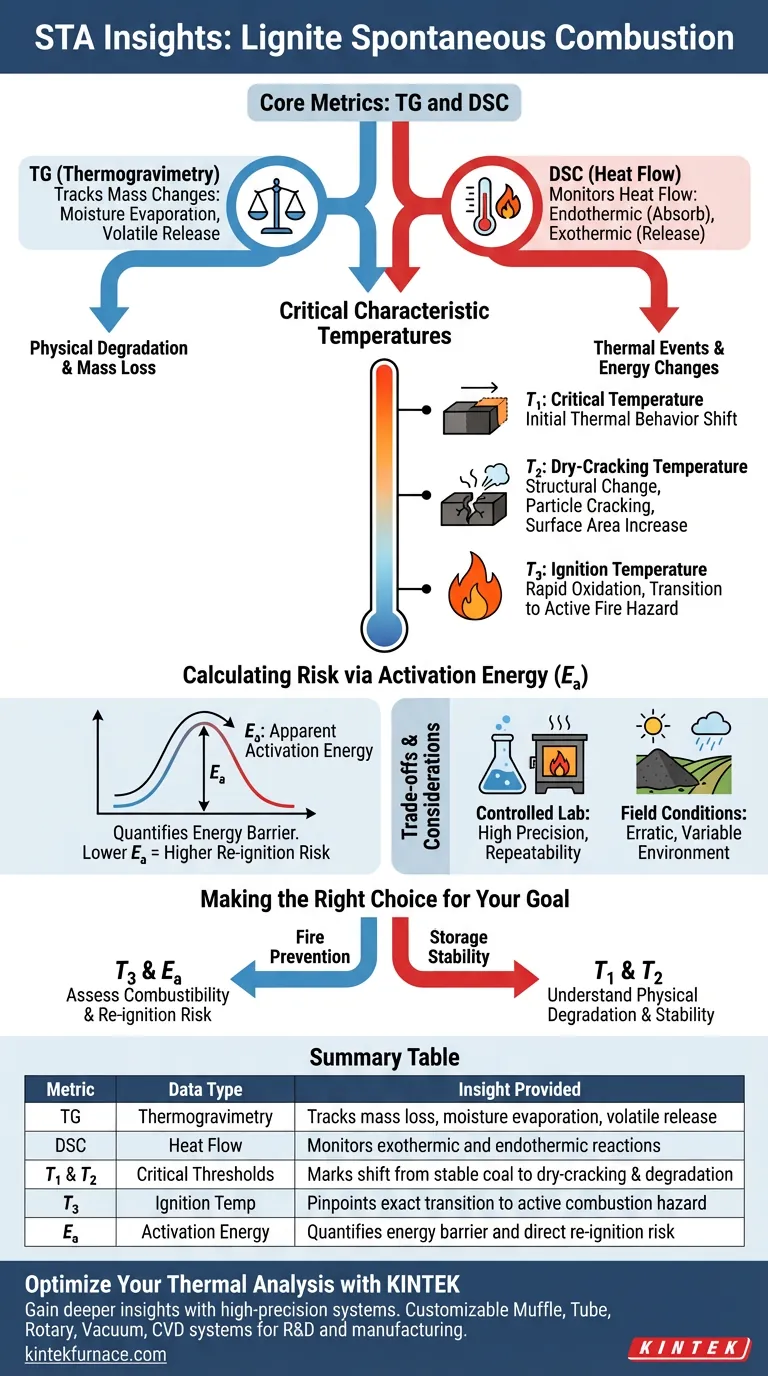

The Core Metrics: TG and DSC

Tracking Mass Changes (TG)

The STA records Thermogravimetry (TG) data, which measures the change in the mass of the coal sample as the temperature rises.

This data stream is essential for observing physical degradation, such as moisture evaporation and the release of volatiles, which precede combustion.

Monitoring Heat Flow (DSC)

Simultaneously, the system records Differential Scanning Calorimetry (DSC) data to track heat flow variations.

This reveals endothermic (heat-absorbing) and exothermic (heat-releasing) reactions, helping you correlate physical mass loss with specific thermal events.

Critical Characteristic Temperatures

The primary value of STA lies in identifying specific temperature points that mark the stages of spontaneous combustion.

Critical Temperature ($T_1$)

This is the first major thermal benchmark identified by the analyzer.

It represents the initial threshold where the coal's thermal behavior begins to shift significantly from its stable state.

Dry-Cracking Temperature ($T_2$)

The STA identifies the dry-cracking temperature ($T_2$), which occurs as the coal continues to heat.

This point marks a structural change in the lignite, often associated with the completion of drying and the onset of particle cracking, which exposes more surface area to oxygen.

Ignition Temperature ($T_3$)

Perhaps the most vital safety metric is the ignition temperature ($T_3$).

This is the point where the oxidation rate becomes rapid enough to sustain combustion, marking the transition from a passive solid to an active fire hazard.

Calculating Risk via Activation Energy

The Significance of Apparent Activation Energy ($E_a$)

Beyond raw temperature data, the STA provides the necessary inputs to calculate the apparent activation energy ($E_a$).

This calculated value is critical because it quantifies the energy barrier that must be overcome for the reaction to occur.

Reflecting Re-ignition Risk

The $E_a$ value directly reflects the degree of re-ignition risk for the specific coal sample.

A lower activation energy typically implies that the coal requires less energy to react, making it more prone to spontaneous combustion and re-ignition.

Understanding the Trade-offs

Controlled Environment vs. Field Conditions

The STA operates using controlled heating, which ensures high precision and repeatability.

However, this controlled ramp rate may not perfectly simulate the erratic and variable environmental conditions found in a stockpile or mine.

Data Interpretation

While STA provides high-precision data points like $T_1$ and $T_3$, these are specific to the sample size and heating rate used in the lab.

Directly extrapolating these specific temperature points to large-scale scenarios requires careful engineering judgment.

Making the Right Choice for Your Goal

To effectively utilize STA data for lignite investigation, align your focus with your specific safety or operational objectives.

- If your primary focus is Fire Prevention: Prioritize the Ignition Temperature ($T_3$) and Activation Energy ($E_a$) to assess how easily the coal will combust under standard conditions.

- If your primary focus is Storage Stability: Analyze the Critical Temperature ($T_1$) and Dry-Cracking Temperature ($T_2$) to understand how the coal degrades physically before it ever reaches the point of ignition.

By leveraging STA data, you move from guessing about coal stability to making decisions based on precise thermal evidence.

Summary Table:

| Metric | Data Type | Insight Provided |

|---|---|---|

| TG | Thermogravimetry | Tracks mass loss, moisture evaporation, and volatile release. |

| DSC | Heat Flow | Monitors exothermic and endothermic reactions during combustion. |

| T1 & T2 | Critical Thresholds | Marks the shift from stable coal to dry-cracking and degradation. |

| T3 | Ignition Temp | Pinpoints the exact transition to active combustion hazard. |

| Ea | Activation Energy | Quantifies the energy barrier and direct re-ignition risk levels. |

Optimize Your Thermal Analysis with KINTEK

Gain deeper insights into material stability with high-precision laboratory solutions. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your specific R&D and manufacturing requirements.

Whether you are investigating spontaneous combustion in coal or developing advanced materials, our expert-backed thermal equipment ensures repeatable, accurate results.

Ready to elevate your research? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Baoshan Jia, Xian Wu. Effects of pre-oxidation temperature and air volume on oxidation thermogravimetric and functional group change of lignite. DOI: 10.1371/journal.pone.0316705

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Ultra High Vacuum CF Flange Stainless Steel Sapphire Glass Observation Sight Window

People Also Ask

- How is SEM utilized to evaluate manganese phosphate catalysts after calcination? Verify Nanosheet Integrity.

- What morphological changes occur in POMOF after treatment? Unlock High Catalytic Performance via Thermal Evolution

- Why is a high-precision constant temperature drying oven required for biochar? Protect Delicate Pore Structures

- What role does Thermogravimetric Analysis (TGA) play in determining the calcination parameters for manganese phosphate?

- What are the advantages of PVD? Achieve High-Performance, Durable Coatings

- What problem does a fluidized bed address in ceramic molds? Ensure Uniform Shells for High-Temp Casting

- What processing conditions does an industrial heating furnace provide during hot forging? Optimize Fe-Mn-Si Alloys

- What is the primary purpose of using a laboratory constant temperature drying oven for fuel sample preparation?