The primary advantages of Physical Vapor Deposition (PVD) are its ability to produce exceptionally pure, durable, and uniform coatings in an environmentally friendly process. This vacuum-based technique provides superior adhesion compared to many other methods, making it an ideal choice for applying high-performance metal and dielectric films onto a wide variety of substrates.

PVD is not merely a coating method; it is a precision engineering process. It excels in applications where performance is non-negotiable, allowing for the atomic-level deposition of extremely dense and well-adhered films that are impossible to achieve with conventional "wet" chemistry processes.

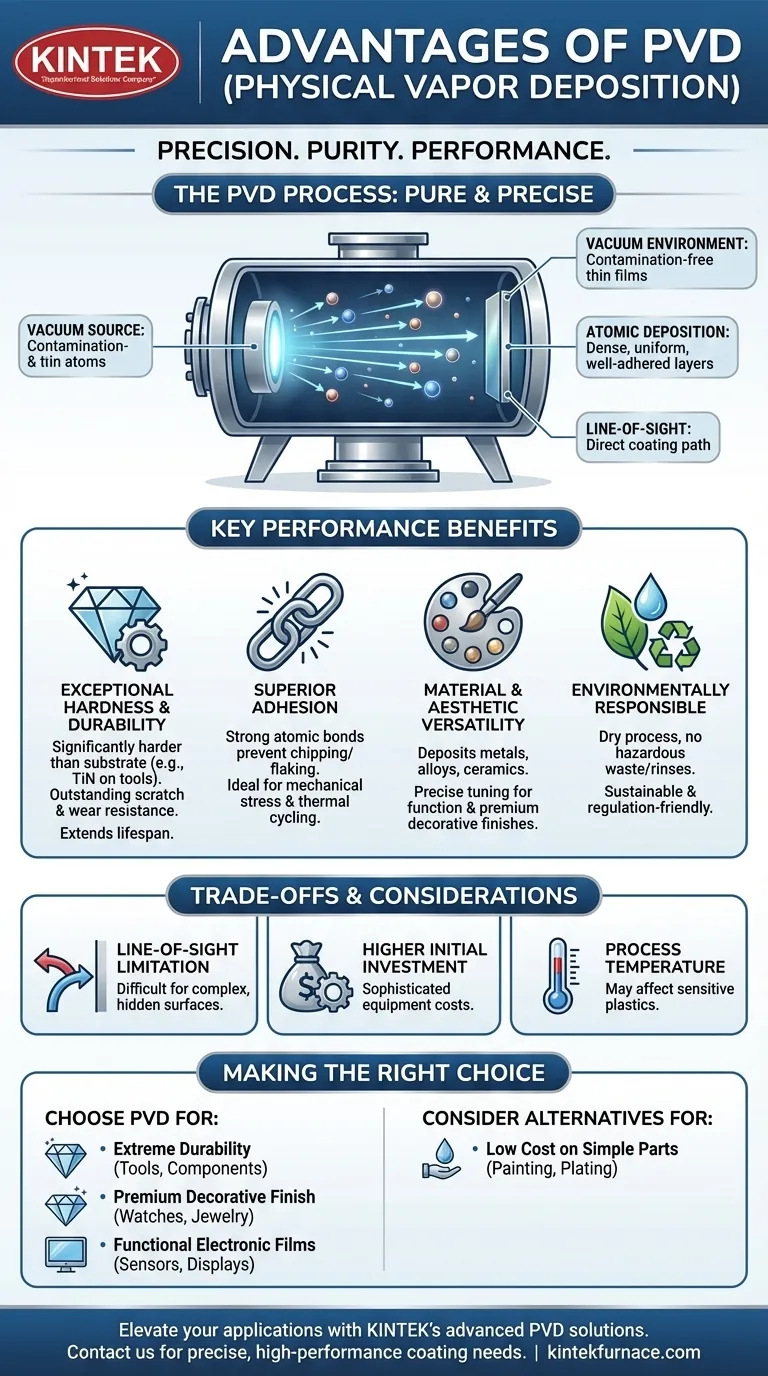

The Foundation: A Process Built for Purity and Precision

Physical Vapor Deposition is fundamentally different from painting or electroplating. The entire process takes place inside a high-vacuum chamber, which is the source of its key advantages.

The Vacuum Environment: Purity by Design

The vacuum chamber is evacuated of air and other reactive gases before the coating process begins. This ensures that the coating material—which is vaporized from a solid source—travels to the substrate with virtually no contamination.

The result is a thin film of exceptionally high purity, free from the oxides and impurities that can plague other methods and compromise performance.

Atomic-Level Deposition: Building a Perfect Film

Inside the vacuum, the vaporized material travels in a straight line and condenses onto the substrate atom by atom. This line-of-sight deposition builds a film that is incredibly dense, uniform, and adherent.

This meticulous layering process is what gives PVD coatings their signature performance characteristics.

Key Performance Advantages Explained

The unique nature of the PVD process translates directly into tangible benefits across different industries, from cutting tools to luxury watches.

Exceptional Hardness and Durability

PVD is renowned for creating coatings that are significantly harder than the substrate material itself. For example, Titanium Nitride (TiN) coatings applied to cutting tools dramatically increase their lifespan and performance.

This hardness translates directly to outstanding scratch and wear resistance, making it ideal for high-contact and high-wear applications.

Superior Adhesion

The high-energy particles created during the PVD process embed themselves into the substrate's surface, forming an extremely strong atomic bond. This prevents the coating from chipping, flaking, or peeling.

This level of adhesion is critical for components subjected to mechanical stress, thermal cycling, or harsh environments.

Material and Aesthetic Versatility

PVD can deposit a vast range of materials, including metals, alloys, and ceramics (dielectrics). This allows for precise tuning of a coating's functional properties, such as its color, conductivity, or corrosion resistance.

This versatility makes it a preferred choice for decorative finishes on consumer goods, offering vibrant, long-lasting colors that are far more durable than traditional plating.

An Environmentally Responsible Choice

PVD is a "dry" and clean physical process. It produces no hazardous chemical waste, rinses, or sludges, unlike wet chemistry processes like electroplating.

This minimal environmental footprint makes PVD a more sustainable and regulation-friendly technology for modern manufacturing.

Understanding the Trade-offs and Considerations

While powerful, PVD is not the universal solution for every coating need. Objectivity requires acknowledging its limitations.

The Line-of-Sight Limitation

Because the vaporized material travels in a straight line, PVD is not well-suited for coating complex internal geometries or the hidden surfaces of intricate parts. The coating can only form on surfaces that have a direct line-of-sight to the source material.

Higher Initial Investment

PVD systems are sophisticated pieces of equipment that require a significant capital investment. The machinery and the need for a controlled vacuum environment make the upfront cost higher than traditional coating setups.

Process Temperature

While considered a "low-temperature" process compared to some alternatives like Chemical Vapor Deposition (CVD), PVD can still operate at temperatures that may be unsuitable for certain sensitive plastics or low-melting-point materials.

Making the Right Choice for Your Application

To determine if PVD is the correct technology, you must align its advantages with your primary goal.

- If your primary focus is extreme durability and performance: PVD is the industry standard for creating hard, wear-resistant coatings on cutting tools, molds, and high-wear mechanical components.

- If your primary focus is a premium decorative finish: PVD provides a durable, vibrant, and long-lasting finish superior to traditional plating for items like watches, jewelry, and architectural hardware.

- If your primary focus is functional electronic films: PVD's precision and purity are essential for creating the thin conductive or dielectric layers required in semiconductors, displays, and sensors.

- If your primary focus is low cost on a simple part: You should evaluate simpler methods like painting or electroplating, as PVD's cost and complexity may be unnecessary.

Ultimately, choosing PVD is an investment in unparalleled precision, durability, and quality for your most demanding applications.

Summary Table:

| Advantage | Description |

|---|---|

| High Purity | Vacuum environment prevents contamination, ensuring pure coatings. |

| Durability | Creates hard, scratch-resistant films for long-lasting performance. |

| Superior Adhesion | Strong atomic bonds prevent chipping and flaking. |

| Material Versatility | Deposits metals, alloys, and ceramics for varied applications. |

| Eco-Friendly | Dry process with no hazardous waste, supporting sustainability. |

Elevate your applications with KINTEK's advanced PVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories and industries with high-temperature furnace systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise solutions for your unique coating needs, enhancing durability, purity, and performance. Contact us today to discuss how we can optimize your processes and deliver superior results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings