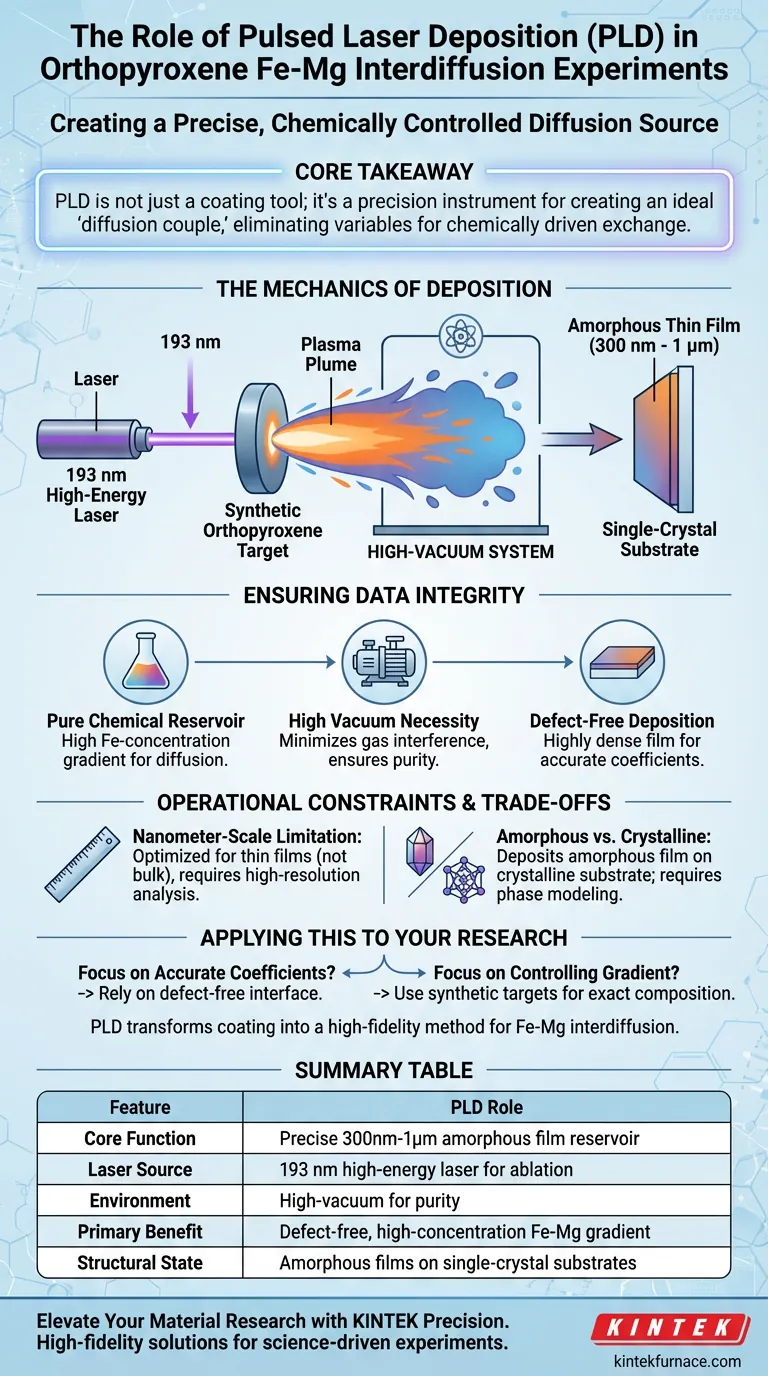

The primary role of a Pulsed Laser Deposition (PLD) system in these experiments is to fabricate a precise, chemically controlled "diffusion source" directly onto the sample surface. By utilizing high-energy 193 nm laser pulses to ablate synthetic orthopyroxene targets, the system deposits a thin, amorphous film (300 nm to 1 µm thick) onto single-crystal substrates, creating a high-concentration iron reservoir essential for driving the diffusion process.

Core Takeaway The PLD system is not merely a coating tool; it is a precision instrument used to create an ideal "diffusion couple." It eliminates experimental variables by producing a defect-free, chemically specific film that ensures the Fe-Mg exchange is driven solely by the intended chemical gradient, rather than by surface impurities or structural inconsistencies.

The Mechanics of Deposition

To understand the PLD's value, you must first understand how it manipulates material at the atomic level to create the experimental setup.

Laser Ablation and Plasma Formation

The process begins with a 193 nm wavelength laser. This high-energy beam strikes a synthetic orthopyroxene target.

The energy is so intense that it ablates the target material, instantly converting it into a plasma plume. This plume contains the atomic constituents of the orthopyroxene.

Controlled Film Growth

This plasma plume travels through the chamber and condenses onto a single-crystal substrate.

This results in the growth of an amorphous thin film. The system allows researchers to target a specific film thickness, typically falling between 300 nm and 1 µm.

Ensuring Data Integrity

The quality of the diffusion data is directly tied to the quality of the initial interface between the sample and the iron source.

Creating a Pure Chemical Reservoir

The primary purpose of this deposited film is to serve as a high-concentration iron reservoir.

For Fe-Mg interdiffusion to occur, there must be a strong chemical gradient. The PLD film provides this by placing a known, iron-rich composition in direct contact with the substrate.

The Necessity of High Vacuum

As noted in supplementary technical data, the PLD process occurs within a high-vacuum system.

This environment is critical because it minimizes interference from ambient gas molecules. It ensures that the atomic flux from the laser plume lands directly on the substrate without scattering.

Defect-Free Deposition

The combination of the vacuum environment and the ablation mechanics results in a highly dense, defect-free film.

This is vital for experiments. If the film were porous or filled with defects, the diffusion rates measured would be inaccurate, reflecting the poor quality of the contact rather than the intrinsic properties of the orthopyroxene.

Operational Constraints and Trade-offs

While PLD offers superior precision, it introduces specific operational requirements that must be managed.

Nanometer-Scale Limitation

PLD is optimized for nanometer-scale thin films. It is not designed to deposit bulk materials (millimeters thick).

Researchers must design their experiments to work within the 300 nm to 1 µm range. This requires high-resolution analytical tools to measure the subsequent diffusion profiles, as the diffusion distances will be relatively short compared to bulk couples.

Amorphous vs. Crystalline Structure

The PLD deposits an amorphous (non-crystalline) film onto a single-crystal substrate.

While this provides an excellent chemical reservoir, the interface is initially distinct structurally. Researchers must account for this phase difference when modeling the initial stages of the diffusion exchange.

Applying This to Your Research

When designing your experimental protocol, use the PLD system's capabilities to align with your specific data requirements.

- If your primary focus is determining accurate diffusion coefficients: Rely on the PLD to create a defect-free interface, ensuring that the measured exchange is not an artifact of poor surface contact.

- If your primary focus is controlling the chemical gradient: Use the PLD's ability to ablate synthetic targets to set the exact initial chemical composition of your iron reservoir.

Ultimately, the PLD system transforms a standard coating process into a high-fidelity method for initializing the chemical potential necessary to measure Fe-Mg interdiffusion with exactitude.

Summary Table:

| Feature | PLD Role in Fe-Mg Interdiffusion Experiments |

|---|---|

| Core Function | Deposits a precise 300 nm to 1 µm amorphous thin film as a chemical reservoir. |

| Laser Source | 193 nm high-energy laser for target ablation and plasma plume formation. |

| Environment | High-vacuum chamber to ensure purity and minimize atomic scattering. |

| Primary Benefit | Creates a defect-free, high-concentration Fe-Mg gradient for accurate coefficients. |

| Structural State | Produces amorphous films on single-crystal substrates for ideal diffusion couples. |

Elevate Your Material Research with KINTEK Precision

High-fidelity diffusion experiments demand absolute purity and control. KINTEK provides industry-leading laboratory solutions, including customizable CVD, Vacuum, and High-Temperature Furnace systems designed to meet the rigorous demands of advanced geochemical and material science research.

Backed by expert R&D and manufacturing, our equipment ensures your experiments are driven by science, not variables. Whether you need specialized high-temp furnaces or bespoke thin-film deposition environments, KINTEK is your partner in precision.

Contact KINTEK Experts Today to Discuss Your Unique Research Needs

Visual Guide

References

- Maria A. Dias, Ralf Dohmen. Experimental determination of Fe–Mg interdiffusion in orthopyroxene as a function of Fe content. DOI: 10.1007/s00410-024-02110-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is the function of an industrial drying oven in ZnZrOx catalyst prep? Ensure Uniform Metal Precursor Adsorption

- What is the purpose of using a preheated stainless steel plate when processing molten glass? Avoid Thermal Stress.

- What is a batch furnace and how does it operate? Master Precision Heat Treatment for Diverse Applications

- Why is the use of a vacuum oven mandatory for drying Ti3C2Tx MXene precursors? Protect Your Advanced 2D Materials

- What are the primary advantages of industrial microwave heating equipment? Enhanced Uranium Recovery Through Innovation

- Why is high-purity argon gas required for MTO synthesis? Ensure Stability in Rhenium Organometallic Catalysis

- Why must MgO for MKPC be produced at 1600°C? Mastering Chemical Kinetics for High-Performance Modification Slurries

- What is the role of sintering in CsPbBr3-SiO2 preparation? Unlock Ultra-Stability with Precise Thermal Sealing