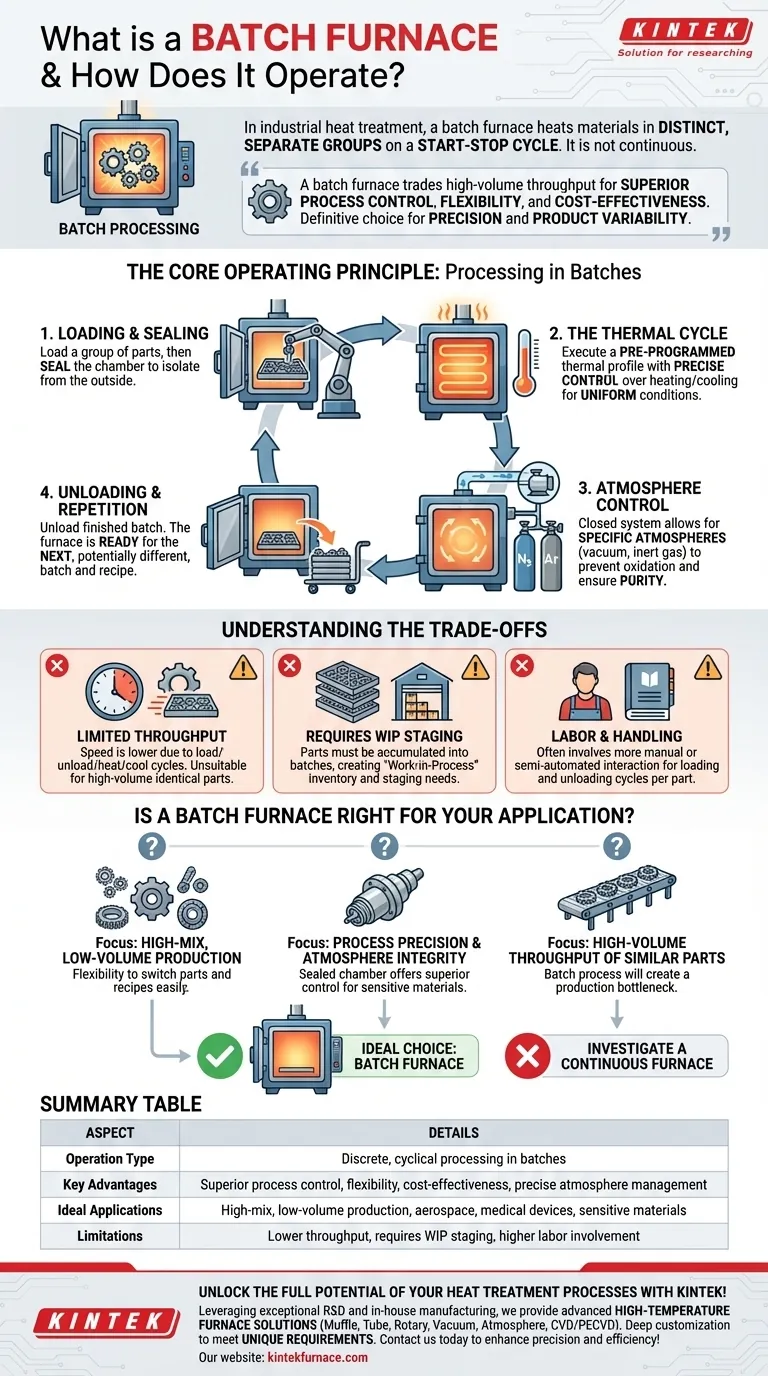

In industrial heat treatment, a batch furnace is a type of thermal processing equipment that heats materials in distinct, separate groups. Unlike a continuous furnace where parts move through steadily, a batch furnace operates on a start-stop cycle: a "batch" of materials is loaded, the chamber is sealed, the heating process is run, and the finished batch is unloaded before the next one can begin.

A batch furnace trades the high-volume throughput of a continuous system for superior process control, flexibility, and cost-effectiveness. It is the definitive choice for applications where precision and product variability are more important than sheer production speed.

The Core Operating Principle: Processing in Batches

The fundamental operation of a batch furnace is defined by its discrete, cyclical nature. Each cycle is a self-contained process, allowing for immense control and customization.

Loading and Sealing

The process begins by loading a group of parts, either manually or via automation, into the furnace chamber. Once loaded, the door is closed and sealed. This act of sealing is critical, as it isolates the internal chamber from the outside environment, creating a controlled system.

The Thermal Cycle

With the chamber sealed, the furnace executes a specific, pre-programmed thermal profile. It provides precise control over both heating and cooling rates, ensuring all parts in the batch experience uniform temperature conditions. This is essential for meeting strict specifications for processes like annealing, tempering, or carburizing.

Atmosphere Control

Because the chamber is a closed system, it is exceptionally well-suited for applications requiring a specific atmosphere. The air can be evacuated to create a vacuum or replaced with an inert gas like nitrogen or argon to prevent oxidation and ensure material purity, a key requirement for cleanroom standards.

Unloading and Repetition

After the thermal cycle is complete and the parts have cooled appropriately, the door is unsealed and the finished batch is removed. The furnace is now ready to receive the next batch, which can be for a completely different part or require a totally different thermal recipe.

Understanding the Trade-offs

While powerful, the batch furnace model is not universally optimal. Understanding its inherent limitations is key to making an informed decision.

Limited Production Throughput

The primary trade-off is speed. The time spent loading, unloading, heating, and cooling for each individual batch means overall throughput is significantly lower than a continuous furnace. This makes it unsuitable for high-volume manufacturing of identical parts.

Requires Work-in-Process Staging

Effective use of a batch furnace requires logistical planning. Parts must be accumulated and organized into appropriately sized batches before processing can begin. This creates a need for "work in process" (WIP) inventory and staging areas.

Labor and Handling

Compared to a fully automated continuous line, a batch process typically involves more labor for loading and unloading cycles. While automation is possible, the start-stop nature often requires more operator interaction per part processed.

Is a Batch Furnace Right for Your Application?

Choosing the correct furnace technology depends entirely on your specific production goals and the nature of the parts you are processing.

- If your primary focus is high-mix, low-volume production: A batch furnace is the ideal choice due to its flexibility to switch between different part types and process recipes with ease.

- If your primary focus is process precision and atmosphere integrity: The sealed-chamber design offers superior control for sensitive materials, aerospace components, or medical devices.

- If your primary focus is high-volume throughput of similar parts: You should investigate a continuous furnace, as the batch process will inevitably create a production bottleneck.

Ultimately, selecting the right furnace technology starts with a clear assessment of your operational priorities and constraints.

Summary Table:

| Aspect | Details |

|---|---|

| Operation Type | Discrete, cyclical processing in batches |

| Key Advantages | Superior process control, flexibility, cost-effectiveness, precise atmosphere management |

| Ideal Applications | High-mix, low-volume production, aerospace, medical devices, sensitive materials |

| Limitations | Lower throughput, requires WIP staging, higher labor involvement |

Unlock the full potential of your heat treatment processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our batch furnaces can enhance your precision and efficiency!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment

- What technical requirements affect the external thermal strength of furnace tubes? Optimize for High-Temp Performance

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing