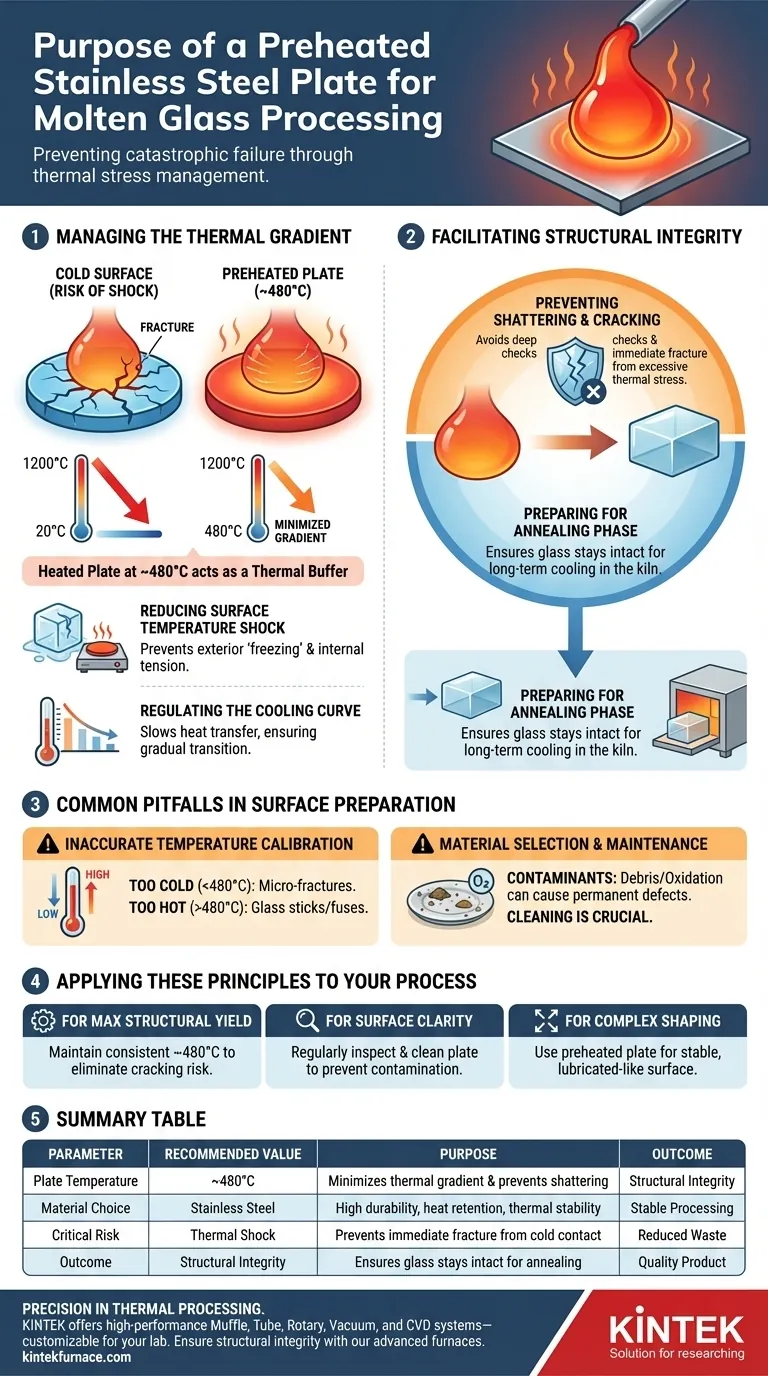

The primary purpose of a preheated stainless steel plate is to prevent catastrophic failure of molten glass through thermal stress management. By using a plate heated to approximately 480°C, technicians can facilitate the initial shaping of the material while strictly regulating its cooling rate. This temperature-controlled contact surface is essential for maintaining the structural integrity of the glass block before it enters the final annealing stage.

Preheating the contact surface minimizes the thermal gradient between the molten glass and the tool, preventing the material from shattering due to localized thermal shock. This process ensures the glass remains intact and structurally sound for subsequent processing.

Managing the Thermal Gradient

Reducing Surface Temperature Shock

When molten glass contacts a cold surface, the exterior layer "freezes" and contracts much faster than the molten core. This massive temperature difference, known as a thermal gradient, creates internal tension that can lead to immediate fracture.

Regulating the Cooling Curve

A plate preheated to 480°C acts as a thermal buffer, slowing the transfer of heat away from the glass. By controlling this initial cooling phase, the glass transitions more gradually from a liquid to a solid state, reducing the risk of internal strain.

Facilitating Structural Integrity

Preventing Shattering and Cracking

The most critical risk in glass processing is excessive thermal stress. Without a preheated surface, the glass is likely to shatter or develop deep "checks" (surface cracks) that compromise the entire block.

Preparing for the Annealing Phase

Initial shaping on a heated plate ensures the glass block stays in one piece long enough to reach the annealing kiln. Proper preparation at this stage is the only way to ensure the material survives the long-term cooling process required for a finished product.

Common Pitfalls in Surface Preparation

Inaccurate Temperature Calibration

If the plate is heated significantly below 480°C, the glass may still experience enough shock to cause micro-fractures. Conversely, if the plate is too hot, the glass may stick or fuse to the stainless steel, ruining the surface finish.

Material Selection and Maintenance

Stainless steel is chosen for its durability and heat retention, but surface contaminants can affect the glass. Any debris or oxidation on the plate can be pressed into the molten glass, creating permanent visual or structural defects.

Applying These Principles to Your Process

When utilizing preheated surfaces in glasswork, your specific goals will dictate how you manage the environment.

- If your primary focus is maximizing structural yield: Ensure your plate is consistently maintained at 480°C to eliminate the risk of cracking during the critical shaping window.

- If your primary focus is surface clarity: Regularly inspect and clean the stainless steel plate to prevent the transfer of metallic oxides or debris to the molten glass.

- If your primary focus is complex shaping: Use the preheated plate to provide a stable, lubricated-like surface that allows the glass to be moved without sticking or premature hardening.

By precisely controlling the temperature of the contact surface, you transform a high-risk material transition into a predictable, stable manufacturing step.

Summary Table:

| Parameter | Recommended Value | Purpose in Glass Processing |

|---|---|---|

| Plate Temperature | ~480°C | Minimizes thermal gradient and prevents shattering |

| Material Choice | Stainless Steel | High durability, heat retention, and thermal stability |

| Critical Risk | Thermal Shock | Prevents immediate fracture from cold surface contact |

| Outcome | Structural Integrity | Ensures glass stays intact for the final annealing phase |

Precision is paramount when managing thermal gradients in glass and material science. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique lab requirements. Ensure the structural integrity of your materials with our advanced high-temperature furnaces. Contact KINTEK today to optimize your thermal processing!

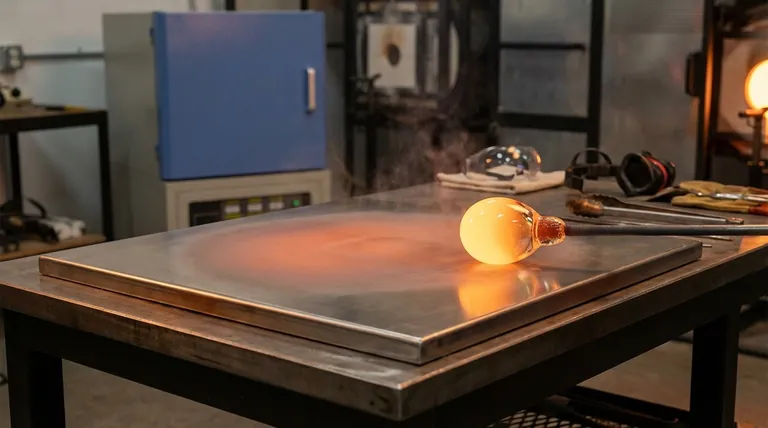

Visual Guide

References

- I. M. Teixeira, J. W. Menezes. Transforming Rice Husk Ash into Road Safety: A Sustainable Approach to Glass Microsphere Production. DOI: 10.3390/ceramics8030093

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a vacuum desiccator used for the preservation of extracted fruit peel extracts? Protect Bioactive Compounds

- What is the function of a drying oven in the chemical activation of biochar with phosphoric acid? Optimize Biochar Quality

- Why is a laboratory vacuum oven utilized for ZnO-FL drying? Preserving Delicate Nanoparticle Morphologies

- How does a laboratory furnace work? Master the Heating Mechanisms for Your Lab

- Why is a two-stage heat treatment required for Ca2Fe2O5? Optimize Your Brownmillerite Synthesis

- What is the function of a pure graphite sheet within a microwave hybrid heating setup? Ensure Pure Ni-BN Cladding

- What is an industrial oven and which industries use it? Discover Versatile Thermal Processing Solutions

- Why is vacuum distillation preferred for biodiesel ethanol removal? Protect Fuel Quality with Low-Temp Processing