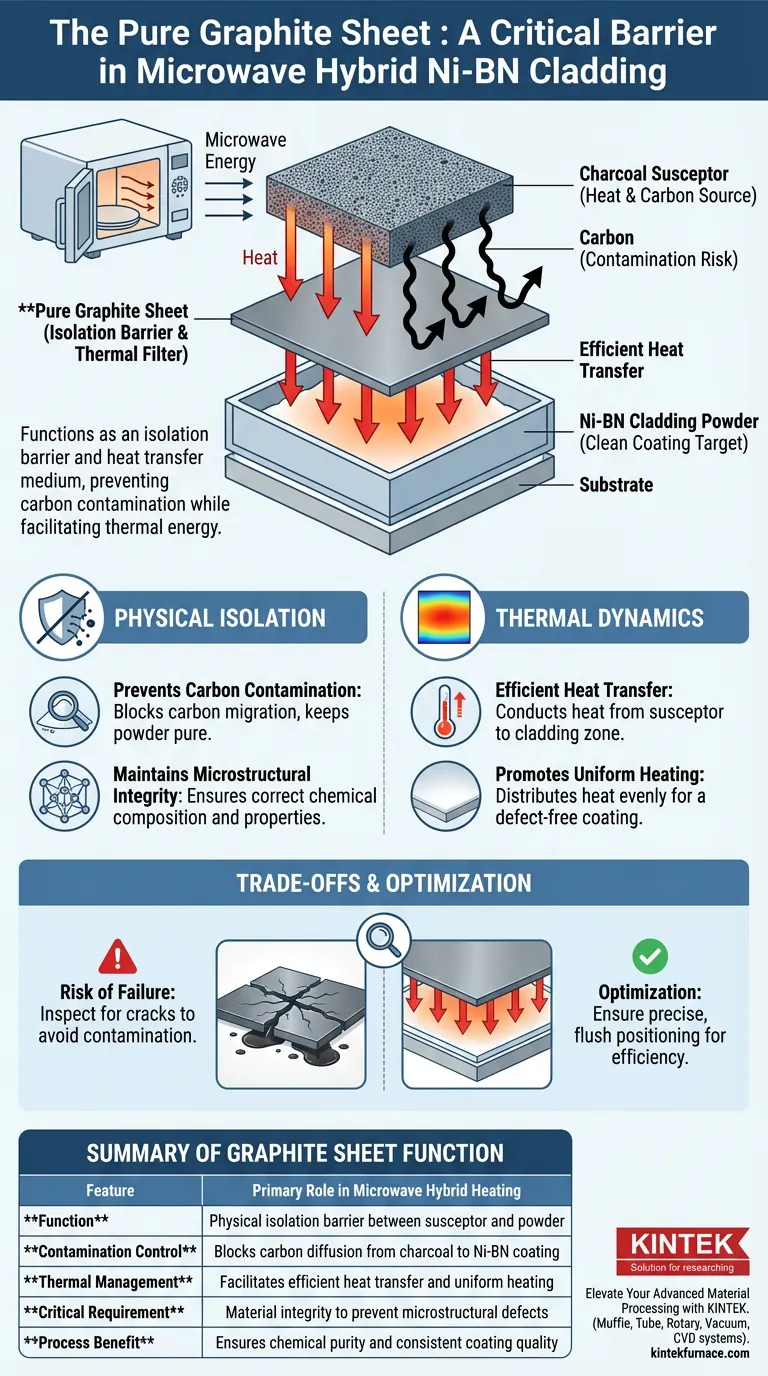

In a microwave hybrid heating setup, the pure graphite sheet functions as a critical isolation barrier positioned between the charcoal susceptor and the Ni-BN cladding powder. Its immediate purpose is to prevent the carbon-rich charcoal from contaminating the nickel-boron nitride coating during the high-temperature process, while simultaneously facilitating the transfer of heat.

The graphite sheet acts as a selective filter: it allows the necessary thermal energy to pass from the susceptor to the cladding powder but physically blocks carbon diffusion to preserve the coating's chemical purity.

The Critical Role of Physical Isolation

Preventing Carbon Contamination

The charcoal susceptor is essential for generating the heat required for cladding, but it introduces a significant risk of impurity.

Without a barrier, carbon atoms from the charcoal would migrate into the Ni-BN powder. The pure graphite sheet stops this diffusion, ensuring the cladding material remains uncontaminated.

Maintaining Microstructural Integrity

The quality of a Ni-BN coating depends heavily on its specific chemical composition.

By blocking external contaminants, the graphite sheet ensures the final microstructure of the coating develops exactly as intended. This isolation is vital for achieving the desired mechanical and physical properties of the cladding.

Managing Thermal Dynamics

Ensuring Efficient Heat Transfer

While the sheet acts as a physical barrier, it must not act as a thermal insulator.

The graphite material is selected because it conducts heat efficiently. It allows the thermal energy generated by the charcoal to pass through to the cladding zone with minimal energy loss.

Promoting Uniform Heating

Microwave heating can sometimes result in localized hot spots.

The graphite sheet helps distribute the heat more evenly across the surface of the cladding powder. This uniformity is crucial for creating a consistent, defect-free coating layer.

Understanding the Trade-offs

The Risk of Barrier Failure

The system relies entirely on the physical integrity of the graphite sheet.

If the sheet is damaged, cracked, or porous, the isolation fails instantly. This leads to immediate carbon contamination, rendering the isolation attempt useless and compromising the coating.

Thermal Lag Potential

While graphite is conductive, introducing any layer between the heat source and the target adds a variable to the thermal equation.

If the sheet is not positioned correctly, it could theoretically impede heat transfer rather than aid it. The setup requires precise positioning to ensure the "hybrid" aspect of the heating remains efficient.

Optimizing Your Cladding Setup

If your primary focus is Chemical Purity:

- Prioritize the physical inspection of the graphite sheet before every run to ensure there are no micro-cracks or defects that could allow carbon diffusion.

If your primary focus is Process Efficiency:

- Ensure the graphite sheet is positioned perfectly flush against both the susceptor and the powder to maximize thermal conductivity and eliminate air gaps.

The success of your Ni-BN cladding relies on treating the graphite sheet not just as a separator, but as an active component of your thermal management strategy.

Summary Table:

| Feature | Primary Role in Microwave Hybrid Heating |

|---|---|

| Function | Physical isolation barrier between susceptor and powder |

| Contamination Control | Blocks carbon diffusion from charcoal to Ni-BN coating |

| Thermal Management | Facilitates efficient heat transfer and uniform heating |

| Critical Requirement | Material integrity to prevent microstructural defects |

| Process Benefit | Ensures chemical purity and consistent coating quality |

Elevate Your Advanced Material Processing with KINTEK

Achieve uncompromising chemical purity and thermal precision in your cladding applications. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab solutions tailored to your unique high-temperature needs. Whether you are optimizing microwave hybrid heating or traditional thermal treatments, our expert systems ensure your coatings maintain perfect microstructural integrity.

Ready to refine your laboratory efficiency? Contact KINTEK today for a customized solution.

Visual Guide

References

- Shashi Prakash Dwivedi, Raghad Ahmed. Revolutionizing Surface Enhancement: Microwave-Assisted Cladding of Ni-Boron Nitride Mixture onto SS-304. DOI: 10.1051/e3sconf/202450701008

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of a high-energy ball mill in NiWO4/GO preparation? Master High-Performance Composite Synthesis

- Why is a constant flow of CO2 maintained during biochar pyrolysis? Unlock Precision Material Engineering

- What methods are used to analyze and characterize graphene samples? Unlock Key Techniques for Accurate Material Analysis

- What is the role of temperature control in MCM-41 synthesis? Master Precision Pore Engineering

- Why is an equivalent diffusion combustion heat source term integrated into the furnace temperature field simulation?

- How do glass-ceramic composite materials provide superior REE-MA immobilization? Enhance Waste Stability & Performance

- How does an aluminum foil mask regulate temperature in the Floating-Zone process? Optimize Crystal Growth Precision

- What is the significance of preheating UHPC molds? Ensure Safety & Longevity with High-Temp Furnaces