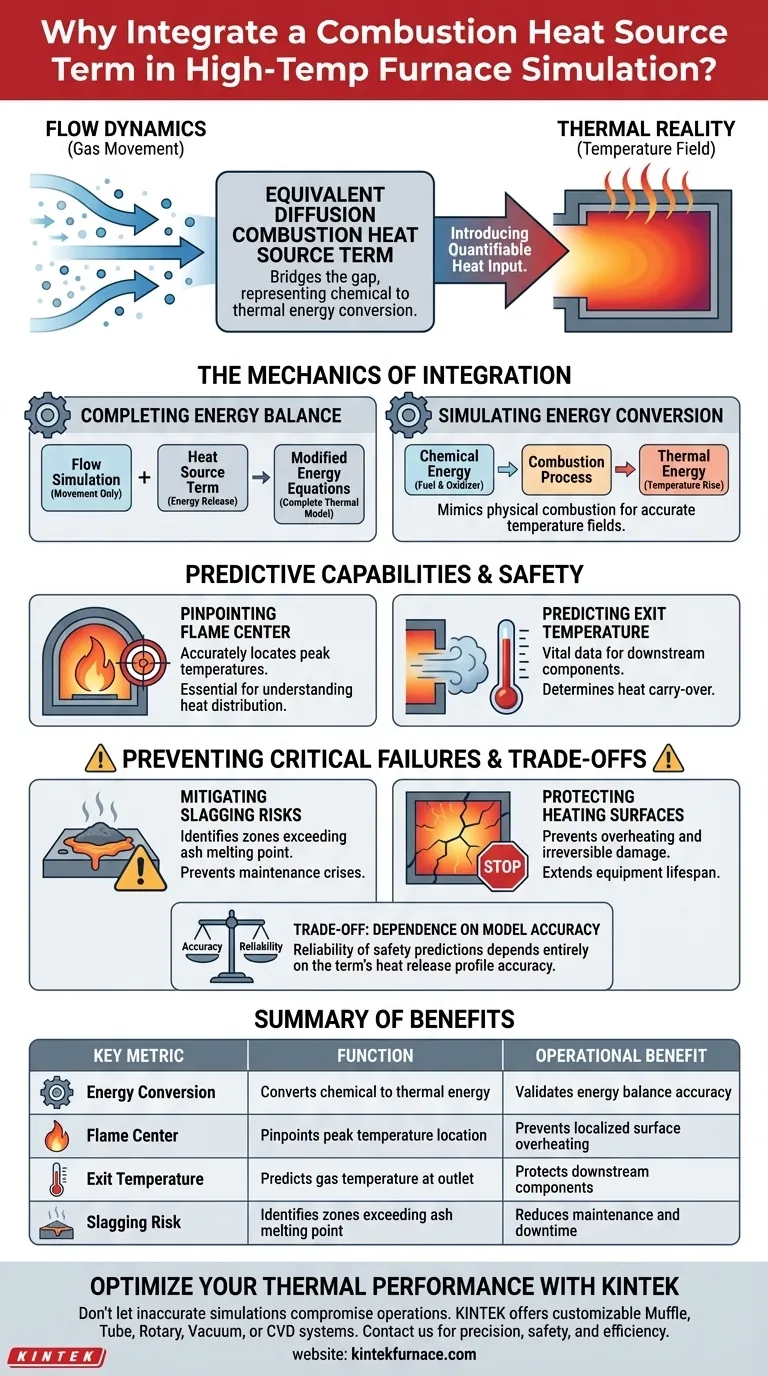

To bridge the gap between flow dynamics and thermal reality, an equivalent diffusion combustion heat source term is integrated into the simulation to mathematically represent the conversion of chemical energy into thermal energy. By adding this term to the energy balance equations, the model can account for the actual heat released during the gas combustion process, which is the primary driver of the furnace's temperature field.

By translating chemical reactions into a quantifiable heat input, this source term enables the precise prediction of flame positioning and exit temperatures, serving as a critical safeguard against slagging and equipment failure.

The Mechanics of the Integration

Completing the Energy Balance

A standard flow simulation calculates how gas moves, but it does not inherently account for heat generation.

The equivalent diffusion combustion heat source term solves this by modifying the energy balance equations. It acts as the mathematical engine that introduces the heat released from burning fuel into the computational domain.

Simulating Energy Conversion

Combustion is a chemical process, but thermal simulations deal with temperature distributions.

This source term effectively converts chemical energy into thermal energy within the model. It allows the simulation to mimic the physical reality of gas combustion, ensuring that the temperature field reflects the actual energy release occurring inside the furnace.

Predictive Capabilities and Operational Safety

Pinpointing the Flame Center

One of the most valuable outputs of this integration is the ability to locate the flame center.

Knowing exactly where the combustion is most intense is essential for understanding heat distribution. The source term ensures the model accurately visualizes where the peak temperatures occur relative to the furnace walls.

Predicting Furnace Exit Temperature

The simulation uses this term to calculate the temperature of the gas as it leaves the combustion zone.

Accurate prediction of the furnace exit temperature is a vital data point for downstream components. It determines how much heat is carried over to subsequent stages of the process.

Preventing Critical Failures

Mitigating Slagging Risks

High-temperature furnaces are prone to slagging, where molten ash accumulates on surfaces.

By accurately simulating the temperature field and flame location, operators can identify zones where temperatures exceed the ash melting point. This predictive capability allows for adjustments to prevent slag buildup before it becomes a maintenance crisis.

Protecting Heating Surfaces

Overheating causes irreversible damage to furnace heating surfaces.

The integration of the heat source term provides the data necessary to ensure temperatures remain within safe material limits. It acts as a preventative tool to avoid surface overheating and extend the lifespan of the equipment.

Understanding the Trade-offs

Dependence on Model Accuracy

The term is described as an "equivalent" source term, implying it is a representation of complex chemistry rather than a molecule-by-molecule simulation.

The reliability of the safety predictions (slagging and overheating) is entirely dependent on the accuracy of this term. If the heat release profile is defined incorrectly in the source term, the predicted flame center will be misplaced, leading to a false sense of security regarding surface temperatures.

Making the Right Choice for Your Simulation

To maximize the value of your high-temperature furnace simulation, align your focus with your specific operational goals:

- If your primary focus is Equipment Safety: Ensure the source term accurately reflects peak load conditions to correctly identify potential overheating zones on heating surfaces.

- If your primary focus is Maintenance Reduction: Use the predicted furnace exit temperature and flame center data to tune operations specifically to keep local temperatures below slagging thresholds.

Accurate integration of the combustion source term is not just a mathematical necessity; it is the foundation for safe and efficient furnace operation.

Summary Table:

| Key Metric | Function in Simulation | Operational Benefit |

|---|---|---|

| Energy Conversion | Converts chemical energy to thermal energy | Validates energy balance accuracy |

| Flame Center | Pinpoints peak temperature location | Prevents localized surface overheating |

| Exit Temperature | Predicts gas temperature at furnace outlet | Protects downstream components |

| Slagging Risk | Identifies zones exceeding ash melting point | Reduces maintenance and downtime |

Optimize Your Thermal Performance with KINTEK

Don't let inaccurate simulations compromise your operations. KINTEK leverages decades of expert R&D and manufacturing to deliver high-performance thermal solutions. Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our furnaces are fully customizable to meet your unique high-temperature lab requirements.

Contact us today to discuss your project and see how our advanced furnace technology ensures precision, safety, and efficiency for your most demanding applications.

Visual Guide

References

- O. I. Varfolomeeva, D. A. Khvorenkov. Development of a universal model for numerical analysis of firebox processes in heat-generating plants. DOI: 10.30724/1998-9903-2025-27-6-171-186

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the function of high-purity nitrogen (N2) during the heating phase of magnetite oxidation? Protect Your Data.

- Why is the continuous injection of high-purity argon required? Achieve Unmatched Purity in Cast Iron Melting

- How are magnetic stirrers and constant temperature drying ovens utilized in the wet chemical synthesis of copper selenide nanorods?

- What role does helium play in nanoparticle synthesis? Unlock Precision via Inert Gas Condensation

- What features can be adjusted in laboratory furnaces based on application requirements? Optimize Your Lab's Thermal Processing

- How does the speed-controlled motor in a high-pressure autoclave influence the yield of glucose from starch?

- What is the purpose of using a laboratory blast drying oven at 107°C for 17 hours for reforming catalysts?

- What are the technical advantages of using vacuum-assisted impregnation for 3D LIG/polymer composites? Boost Strength