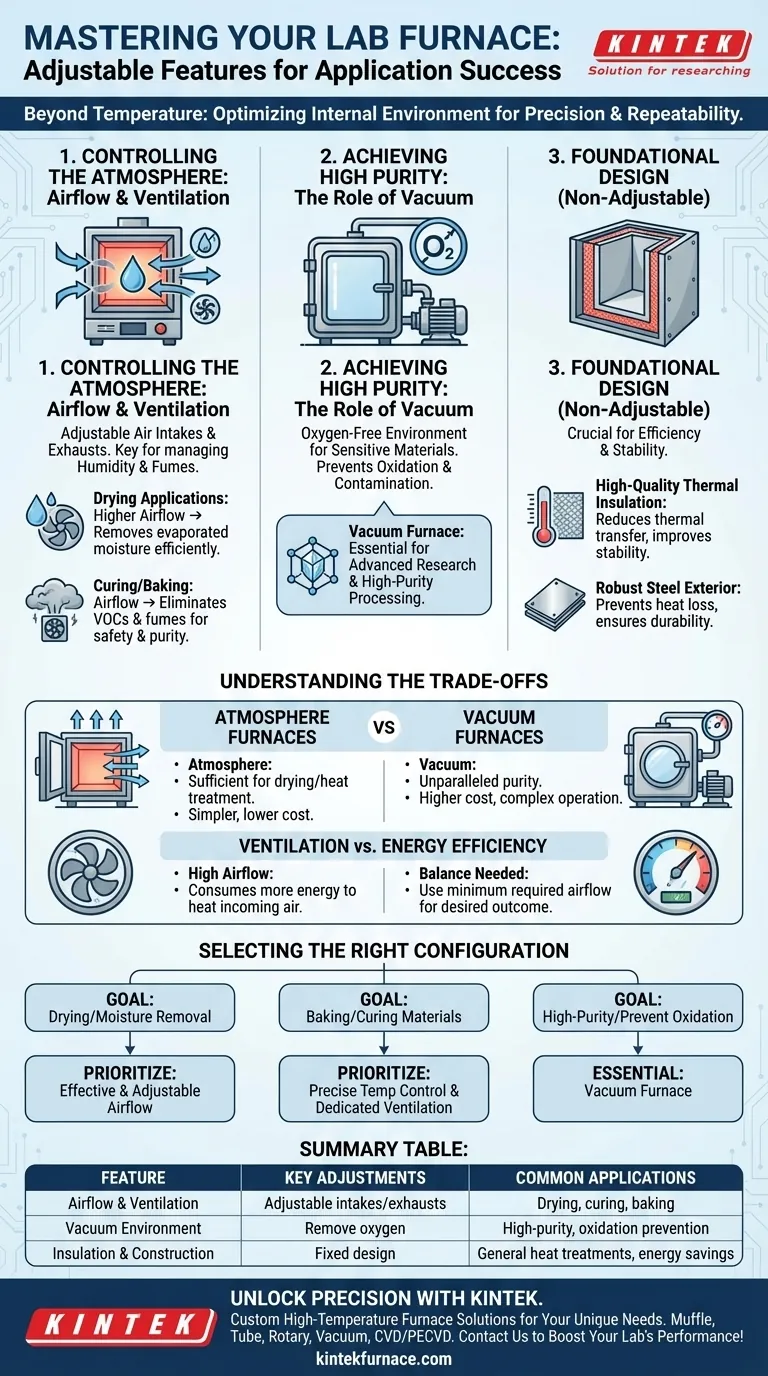

Beyond temperature, the most critical features you can adjust in a laboratory furnace are those that control its internal atmosphere. Specifically, air intakes and exhausts can be modified to manage humidity, vent fumes, or create specific processing environments. More advanced applications may require adjusting the entire environment by using a vacuum furnace to eliminate oxygen and prevent contamination.

The true adaptability of a laboratory furnace lies not just in setting temperature, but in precisely controlling the internal environment. Matching the furnace's atmospheric capabilities—whether through airflow or vacuum—to your specific application is the key to achieving repeatable and accurate results.

Matching Furnace Features to Your Application

A laboratory furnace is more than a simple hot box. Its design features are directly tied to its intended function, whether that is basic drying, complex chemical curing, or high-purity material processing. Understanding these features allows you to select or operate the furnace for optimal performance.

Controlling the Atmosphere: Airflow and Ventilation

The ability to introduce or remove air from the heating chamber is a fundamental adjustable feature.

This is typically managed through adjustable air intakes and exhausts. Manipulating this airflow is critical for processes that release moisture or fumes.

For drying applications, a higher airflow rate is desirable. This allows the furnace to efficiently remove moisture evaporated from the sample and vent it outside the chamber.

For curing or baking, airflow is used to eliminate volatile organic compounds (VOCs) or other fumes that are released as the material is heated, ensuring operator safety and process purity.

Achieving High Purity: The Role of Vacuum

For sensitive materials, the presence of oxygen or other atmospheric gases can be detrimental, causing oxidation and contamination.

A laboratory vacuum furnace addresses this by removing the atmosphere entirely. These systems are designed for high-temperature processing in an oxygen-free environment.

This feature is not merely an "adjustment" but a different class of furnace. It provides exceptional control over final material properties and is essential for advanced research and small-scale production of high-purity components.

Foundational Design: Insulation and Construction

While not adjustable by the user during operation, the furnace's construction dictates its efficiency and stability.

High-quality thermal insulation is a core feature that reduces thermal transfer to the outside environment. This improves energy efficiency and ensures the temperature inside the chamber remains stable and uniform.

A robust steel exterior serves to prevent radiant heat loss and provides structural durability, further contributing to the furnace's thermal efficiency and longevity.

Understanding the Trade-offs

Selecting the right furnace involves balancing its capabilities with its complexity and operational costs. The most advanced features are not always necessary for every task.

Atmosphere vs. Vacuum Furnaces

A standard atmosphere furnace with adjustable ventilation is sufficient for many applications like drying or simple heat treatments. They are generally simpler and less expensive to operate.

A vacuum furnace offers unparalleled purity but comes with higher upfront costs and greater operational complexity, including the need for robust pumping systems and seals.

Ventilation vs. Energy Efficiency

Using high airflow to vent fumes or humidity requires the furnace to constantly heat incoming, cooler air. This process consumes significantly more energy than a static, sealed-chamber operation.

You must balance the need for ventilation against the goal of maintaining energy efficiency. Only use as much airflow as is necessary to achieve your desired outcome, whether it's removing moisture or ensuring a safe work environment.

Selecting the Right Configuration for Your Goal

To ensure your equipment aligns with your process, match the furnace's features directly to your primary objective.

- If your primary focus is drying or moisture removal: Prioritize a furnace with effective and adjustable air intakes and exhausts to efficiently vent humidity.

- If your primary focus is baking or curing materials: Select a furnace with precise temperature control and dedicated ventilation to safely manage and remove fumes or VOCs.

- If your primary focus is high-purity processing or preventing oxidation: A vacuum furnace is essential for creating the controlled, oxygen-free environment your material requires.

By aligning the furnace's capabilities with your specific material goals, you ensure both process integrity and reliable outcomes.

Summary Table:

| Feature | Key Adjustments | Common Applications |

|---|---|---|

| Airflow & Ventilation | Adjustable intakes/exhausts for humidity and fume control | Drying, curing, baking |

| Vacuum Environment | Remove oxygen to prevent contamination | High-purity processing, oxidation prevention |

| Insulation & Construction | Fixed design for efficiency and stability | General heat treatments, energy savings |

Unlock Precision in Your Laboratory with KINTEK

Are you struggling to achieve consistent results in your thermal processes? At KINTEK, we specialize in providing advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—all backed by strong deep customization capabilities. Whether you're working on drying, curing, or high-purity applications, our furnaces ensure precise control over atmosphere, temperature, and more, delivering reliable outcomes and enhanced efficiency.

Don't let equipment limitations hold back your research or production. Contact us today to discuss how we can customize a furnace solution that perfectly matches your application requirements and boosts your lab's performance!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability