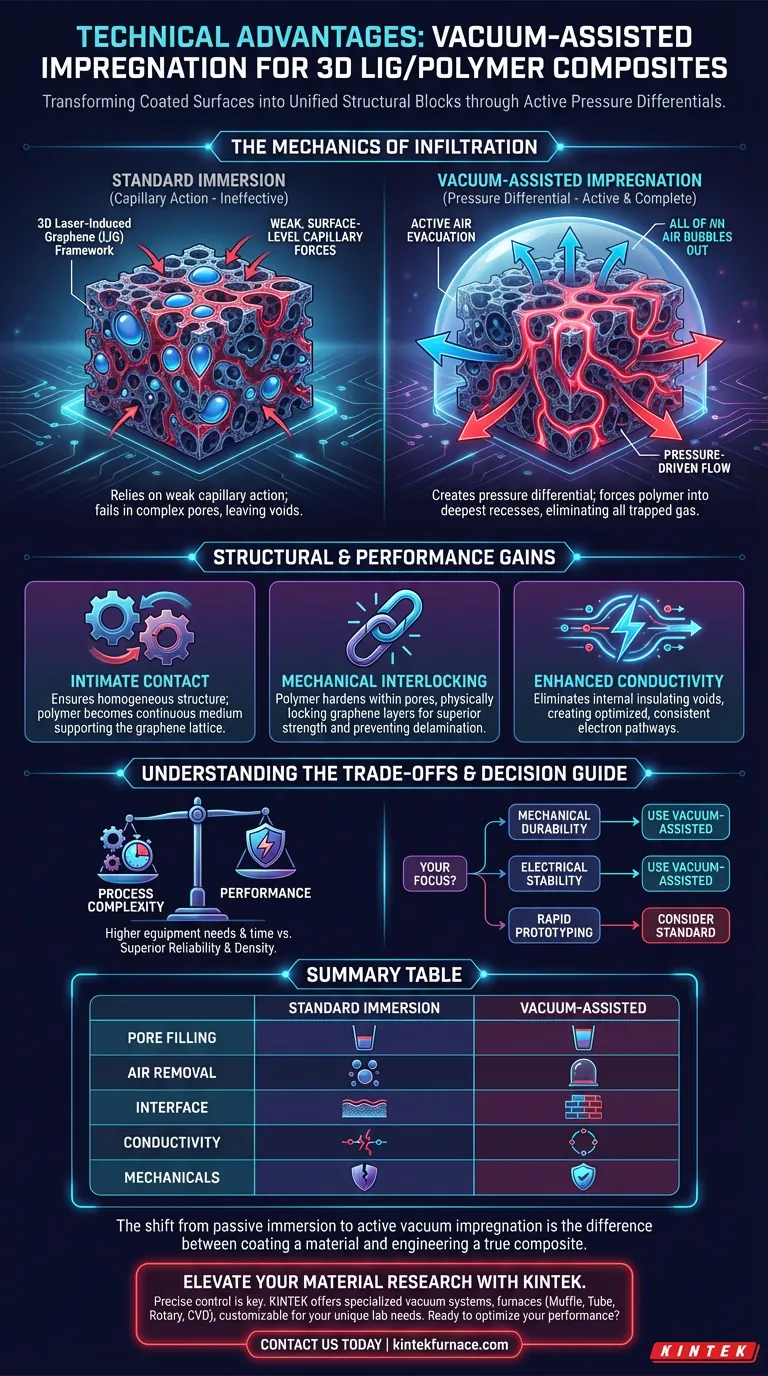

Vacuum-assisted impregnation systematically eliminates structural defects inherent in porous materials to create a superior composite. By utilizing negative pressure, this technique actively evacuates air trapped within the complex micropores of 3D Laser-Induced Graphene (LIG) and forces the polymer matrix—such as epoxy resin or elastomers—into the deepest recesses of the framework.

Core Insight: The fundamental advantage of this method is the conversion of a coated surface into a unified structural block. By replacing void spaces with a solid polymer matrix through pressure differentials, you achieve mechanical interlocking, which is impossible to replicate through standard immersion or surface coating.

The Mechanics of Infiltration

Overcoming Surface Tension and Pore Geometry

Standard immersion methods rely heavily on capillary action, which often fails when facing the intricate, tortuous pore structure of 3D LIG.

Vacuum-assisted impregnation bypasses this limitation by creating a pressure differential. This force physically drives the viscous polymer solution into the micropores, ensuring the resin reaches areas that gravity or capillary action alone cannot access.

Complete Air Evacuation

The primary enemy of composite integrity is trapped gas. The LIG framework naturally holds air within its porous architecture.

Applying a vacuum effectively strips this air out before the polymer cures. This mirrors the defect-reduction principles seen in advanced casting, where removing adsorbed gases is critical to preventing internal voids that act as stress concentrators.

Structural and Performance Gains

Achieving Intimate Contact

For a composite to function effectively, the reinforcement (graphene) and the matrix (polymer) must act as one.

Vacuum impregnation ensures intimate contact between these two phases. This creates a homogeneous internal structure where the polymer is not just a shell, but a continuous medium supporting the graphene lattice.

Mechanical Interlocking

The most significant structural benefit is the creation of a mechanical interlock.

Because the polymer hardens inside the pore structure, it physically locks the graphene layers in place. This reinforcement mechanism significantly improves the mechanical strength of the final part, preventing delamination under stress.

Enhancing Electrical Conductivity

Defects and voids impede the flow of electrons.

By eliminating internal air gaps and ensuring the polymer supports the graphene network without separating it, the composite maintains better electrical pathways. The result is a measurable improvement in electrical conductivity compared to composites fabricated via simple immersion.

Understanding the Trade-offs

Process Complexity vs. Performance

While vacuum-assisted impregnation yields superior material properties, it introduces operational complexity.

Unlike simple dipping, this process requires vacuum chambers and precise pressure control. You are trading the simplicity and speed of fabrication for the reliability and density of the final composite.

Material Compatibility

The success of this technique relies on the viscosity of the polymer.

If the resin is too viscous, even a vacuum may struggle to fully impregnate the smallest micropores. It is essential to balance the vacuum level with the flow characteristics of your specific epoxy or elastomer solution.

Making the Right Choice for Your Goal

To determine if this fabrication method aligns with your project requirements, consider your specific performance metrics.

- If your primary focus is mechanical durability: Use vacuum-assisted impregnation to maximize the mechanical interlocking between the matrix and the graphene, ensuring the composite can withstand physical stress.

- If your primary focus is electrical stability: Rely on this method to eliminate internal voids that disrupt conductivity and create inconsistent electrical performance.

- If your primary focus is rapid prototyping: Acknowledge that this process adds time and equipment overhead compared to standard immersion, and may be overkill for non-critical proofs of concept.

The shift from passive immersion to active vacuum impregnation is the difference between coating a material and engineering a true composite.

Summary Table:

| Feature | Standard Immersion | Vacuum-Assisted Impregnation |

|---|---|---|

| Pore Filling | Partial (Capillary action) | Complete (Pressure differential) |

| Air Removal | Trapped gas creates voids | Active evacuation for zero defects |

| Interface | Surface coating only | Deep mechanical interlocking |

| Conductivity | Disrupted by internal gaps | Optimized electron pathways |

| Mechanicals | Prone to delamination | High strength & structural integrity |

Elevate Your Material Research with KINTEK

Precise control over your fabrication environment is the difference between a simple coating and a high-performance composite. Backed by expert R&D and manufacturing, KINTEK offers specialized vacuum systems, Muffle, Tube, Rotary, and CVD furnaces, all customizable for your unique lab needs.

Whether you are engineering 3D LIG composites or advanced polymers, our high-temp systems provide the stability and precision required for breakthroughs.

Ready to optimize your lab's performance? Contact us today to find the perfect system for your application!

Visual Guide

References

- Laser‐Induced 3D Graphene Enabled Polymer Composites with Improved Mechanical and Electrical Properties Toward Multifunctional Performance. DOI: 10.1002/advs.202509039

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Induction Melting Furnace

People Also Ask

- Why are User-Defined Functions (UDFs) necessary for modeling complex combustion? Unlock Precision in Furnace Simulation

- What are the advantages of a high-pressure nitrogen environment? Speed and Efficiency in Wood Thermal Modification

- How does a hybrid microwave sintering furnace compare to traditional furnaces? Optimize BZT Ceramic Production

- Why is vacuum sealing technology essential for K2In2As3 synthesis? Master High-Purity Solid-State Reactions

- What type of furnace is used for heat treatment? Choose the Right Solution for Your Materials

- Why is it necessary to configure a high-purity nitrogen atmosphere or vacuum system for Al2O3/TiC microwave sintering?

- How does temperature control precision affect SC-NMNO crystal morphology? Master Thermal Fields for High-Quality Grains

- What is the function of coke and flux in lithium battery recycling? Optimize Metal Recovery and Slag Separation