The short answer is that there is no single type of furnace for heat treatment; rather, several distinct categories exist, each designed for specific materials and outcomes. The most common types include batch furnaces (like box or pit furnaces), atmosphere furnaces that control the gaseous environment, and vacuum furnaces that operate without a reactive atmosphere. The choice depends entirely on the metallurgical goal, the material being treated, and the required surface finish.

The most critical factor in selecting a heat treatment furnace is not its shape or size, but its ability to control the environment surrounding the part. The decision to use ambient air, a controlled atmosphere, or a vacuum dictates the quality, properties, and final cost of the treated component.

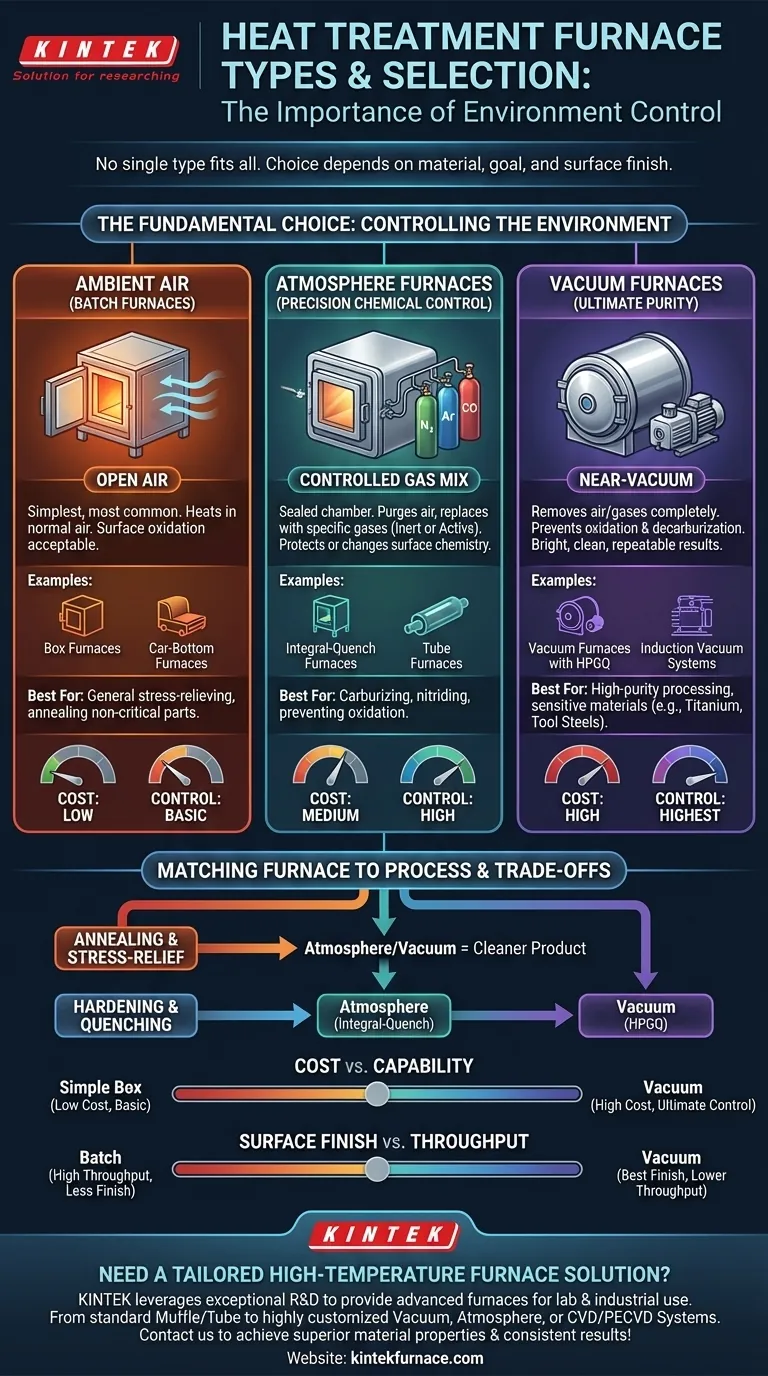

The Fundamental Choice: Controlling the Environment

Nearly all differences between heat treatment furnaces come down to how they manage the atmosphere inside the heating chamber. This control is essential because at high temperatures, the surface of a metal becomes highly reactive with gases like oxygen.

Furnaces for Ambient Air Processing

These are often the simplest and most common types of furnaces, typically falling under the batch furnace category. They heat parts in the presence of normal air.

Examples include box furnaces and car-bottom furnaces. They are well-suited for general-purpose heat treatments like stress-relieving or annealing where some surface oxidation is acceptable or can be easily removed later.

Atmosphere Furnaces: Precision Chemical Control

An atmosphere furnace is a sealed chamber where the air is purged and replaced with a precisely controlled mixture of gases. This is done to achieve specific results that are impossible in open air.

These furnaces can create an inert atmosphere (using nitrogen or argon) to protect the part from oxidation. They can also create an active atmosphere to intentionally change the surface chemistry of the part, such as in carburizing or nitriding processes.

Vacuum Furnaces: The Ultimate Purity

A vacuum furnace is the most advanced type, designed for the highest level of control. It operates by pumping nearly all the air and other gases out of the sealed chamber, creating a near-vacuum environment.

By removing reactive gases like oxygen, a vacuum furnace completely prevents oxidation and decarburization. This results in bright, clean parts that require no post-treatment cleaning. The process is highly repeatable, automated, and ideal for sensitive, high-value materials like titanium or specialized tool steels.

Matching the Furnace to the Process

Different heat treatment goals require different furnace capabilities. The integration of heating and cooling within a single controlled environment is a key factor.

For Annealing and Stress-Relieving

This process aims to soften a metal and relieve internal stresses. While a simple batch furnace can work, using an atmosphere or vacuum furnace prevents scaling and ensures a cleaner final product, improving material quality.

For Hardening and Quenching

Hardening requires heating a material to a critical temperature and then cooling it rapidly (quenching).

Integral-quench furnaces are a type of atmosphere furnace with an internal, sealed quenching tank. This allows the part to be moved from the heating chamber to the quench oil or salt without exposure to air.

Vacuum furnaces accomplish this with High-Pressure Gas Quenching (HPGQ), using inert gas like nitrogen or argon to cool the part rapidly and uniformly inside the vacuum chamber. This all-in-one process minimizes thermal stress and deformation.

For Specialized Applications

Some furnaces are designed for very specific tasks. A tube furnace, for example, is often used in laboratory settings for processing small samples. Some of these may use methods like induction heating to generate heat very quickly and locally within a contained tube.

Understanding the Trade-offs

Choosing a furnace involves balancing capability, cost, and complexity. No single solution is best for every application.

Cost vs. Capability

Simple box furnaces operating in air are the most affordable option. Atmosphere furnaces are more expensive due to the need for gas handling systems, while vacuum furnaces represent the highest capital investment due to their complex chambers, pumps, and control systems.

Surface Finish vs. Throughput

Vacuum furnaces produce the best possible surface finish, eliminating discoloration and the need for secondary cleaning. However, traditional batch furnaces may offer higher throughput for large, less critical components where surface finish is not the primary concern.

Operational Complexity

Operating a basic box furnace is straightforward. In contrast, atmosphere and vacuum furnaces require significant expertise to manage gas flows, pressures, and complex automated cycles to ensure safety and achieve consistent, high-quality results.

Making the Right Choice for Your Goal

Your choice of furnace should be driven by the technical requirements of the final product.

- If your primary focus is general stress relief or annealing non-critical parts: A simple batch furnace (like a box or car-bottom) is often the most cost-effective choice.

- If your primary focus is preventing any surface oxidation or decarburization: A vacuum furnace is the definitive solution, offering the highest level of purity and control.

- If your primary focus is altering the surface chemistry (e.g., carburizing): An atmosphere furnace is necessary to introduce and precisely control the reactive gases required for the process.

- If your primary focus is producing clean, hardened parts with minimal distortion: An integral-quench furnace or a vacuum furnace with gas quenching provides an all-in-one, highly controlled solution.

Ultimately, understanding the interplay between material, process, and environment is the key to selecting the right heat treatment furnace for your application.

Summary Table:

| Furnace Type | Best For | Key Feature |

|---|---|---|

| Batch Furnace (Box, Car-Bottom) | General stress-relieving, annealing | Simple operation, cost-effective |

| Atmosphere Furnace | Carburizing, nitriding, oxidation prevention | Controlled gas environment |

| Vacuum Furnace | High-purity processing, sensitive materials | No oxidation, bright surface finish |

Need a high-temperature furnace tailored to your unique heat treatment process?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace solutions for diverse laboratory and industrial applications. Whether you require a standard Muffle or Tube Furnace or a highly customized Vacuum, Atmosphere, or CVD/PECVD System, our deep customization capabilities ensure your furnace precisely meets your experimental and production requirements.

Let us help you achieve superior material properties and consistent results. Contact our experts today to discuss your specific heat treatment challenges!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How are parts loaded into a vacuum furnace? Ensure Precision and Efficiency in Your Process

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy