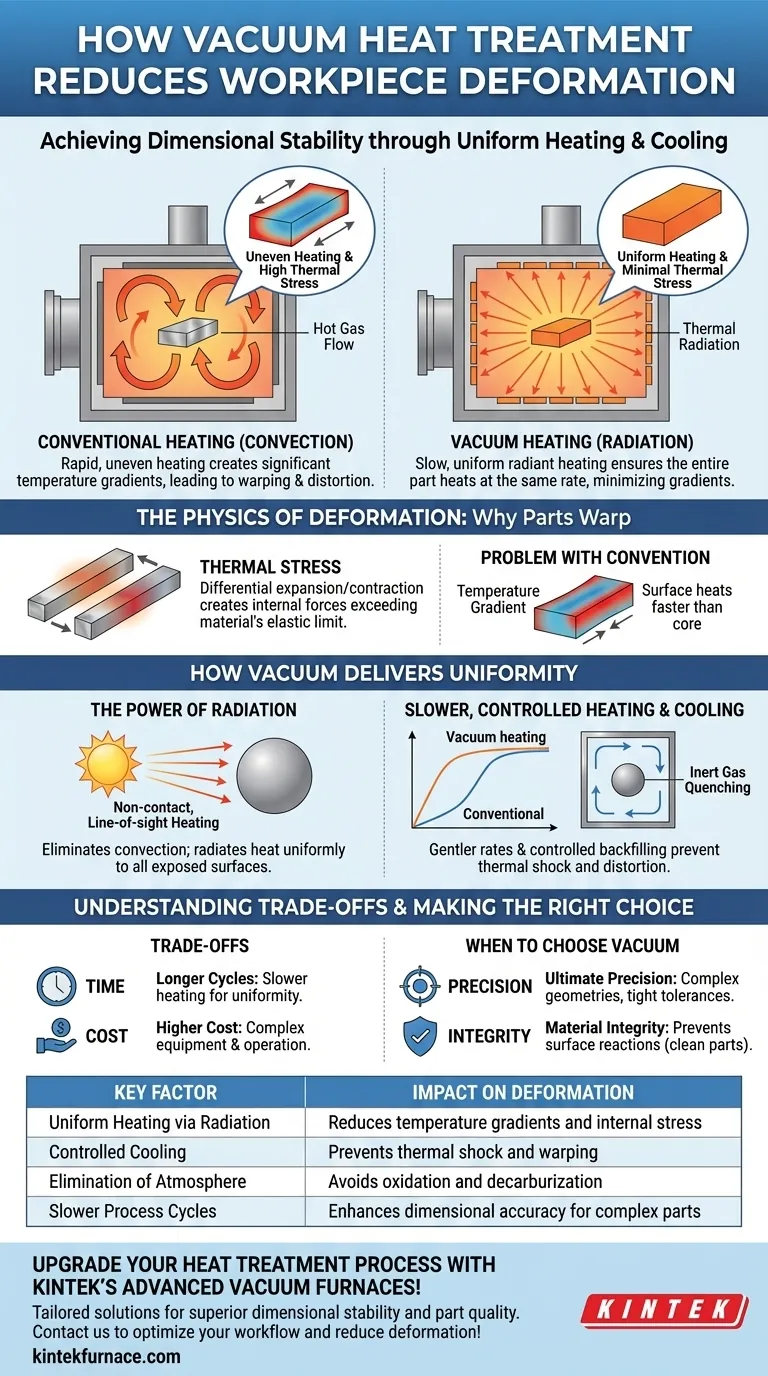

At its core, vacuum heat treatment minimizes workpiece deformation by creating an exceptionally uniform heating and cooling environment. By removing air and relying on thermal radiation, the process ensures the entire part—both its surface and its core—heats up at nearly the same rate, which drastically reduces the internal thermal stresses that cause warping and distortion.

The fundamental advantage of a vacuum furnace is its reliance on radiant heat. Unlike conventional furnaces that use hot gas (convection), radiation heats the workpiece evenly from all directions, preventing the significant temperature differences between the surface and core that are the primary cause of deformation.

The Physics of Deformation: Why Parts Warp

To understand why vacuum treatment is so effective, we must first understand the root cause of deformation during heat treatment: thermal stress.

Thermal Stress: The Root Cause

When a metal part is heated or cooled, it expands or contracts. If one area of the part heats or cools faster than another, these sections expand or contract at different rates.

This differential movement creates powerful internal forces. When these forces exceed the material's elastic limit at high temperatures, the part will permanently change shape, resulting in warping, twisting, or other dimensional inaccuracies.

The Problem with Conventional Heating

Conventional atmosphere furnaces heat parts primarily through convection, using fans to circulate hot gas.

This process is inherently uneven. The surfaces directly hit by the circulating hot gas get hotter much faster than the core of the part or areas that are "shielded" from the gas flow. This creates a significant temperature gradient and, consequently, high levels of thermal stress.

How Vacuum Delivers Uniformity

A vacuum furnace fundamentally changes the physics of heat transfer, which is the key to minimizing deformation.

The Power of Radiation

By removing nearly all the air, a vacuum furnace eliminates convection as the primary mode of heat transfer. Instead, it relies almost entirely on thermal radiation from the furnace's heating elements.

Think of it like the sun heating the Earth. The heat radiates in all directions, warming all exposed surfaces simultaneously. This non-contact, line-of-sight heating is far more uniform than forced hot air, allowing the entire workpiece to absorb energy at a more consistent rate.

Slower, More Controlled Temperature Change

Radiant heating is inherently gentler and more controllable than convection. The process allows for slower, precisely programmed heating rates.

This gives the heat time to "soak" into the part, ensuring the core temperature can keep pace with the surface temperature. This minimal temperature differential is the single most important factor in preventing the buildup of thermal stress.

Uniform Cooling and Quenching

The principle of uniformity extends to the cooling phase. In a vacuum furnace, quenching is often done by backfilling the chamber with a high-purity inert gas like nitrogen or argon, which is then circulated by fans.

Because this happens in a controlled, enclosed environment, the cooling is far more predictable and uniform than plunging a hot part into an oil or water bath, which can cause severe thermal shock and distortion.

Understanding the Trade-offs

While dimensionally superior, vacuum heat treatment is not a universal solution. It involves specific considerations and trade-offs.

Process Time and Cost

The deliberate, slower heating and cooling cycles required for maximum uniformity mean that vacuum furnace cycles are often longer than conventional furnace runs.

Additionally, vacuum furnaces represent a higher capital investment and have more complex operating requirements, which can translate to a higher per-part cost.

Furnace Loading Is Critical

Because heating relies on line-of-sight radiation, how parts are loaded into the furnace is crucial.

Parts placed too close together can create "shadows," where one part blocks the radiant heat from reaching another. This negates the benefit of uniformity and can lead to inconsistent results, so proper spacing and fixturing are essential.

Making the Right Choice for Your Application

The decision to use vacuum heat treatment depends entirely on the requirements of the final component.

- If your primary focus is ultimate precision: Vacuum is the superior choice for parts with complex geometries, thin sections, or mission-critical dimensional tolerances where rework or scrap is unacceptable.

- If your primary focus is maintaining material integrity: Vacuum treatment prevents surface reactions like oxidation and decarburization, resulting in a clean, bright part that doesn't require post-treatment grinding or cleaning.

- If your primary focus is cost-effective, high-volume production: For simpler parts with generous tolerances, traditional atmosphere heat treatment may provide an acceptable result at a lower cost.

Ultimately, choosing vacuum heat treatment is an investment in dimensional stability and final part quality.

Summary Table:

| Key Factor | Impact on Deformation |

|---|---|

| Uniform Heating via Radiation | Reduces temperature gradients and internal stress |

| Controlled Cooling | Prevents thermal shock and warping |

| Elimination of Atmosphere | Avoids oxidation and decarburization |

| Slower Process Cycles | Enhances dimensional accuracy for complex parts |

Upgrade your heat treatment process with KINTEK's advanced vacuum furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental needs are met precisely, delivering superior dimensional stability and part quality. Contact us today to discuss how we can optimize your workflow and reduce deformation in your workpieces!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-precision vacuum drying oven play in composite electrolyte membranes? Ensure High Purity & Integrity

- What are the different types of vacuum heat treatment furnaces? Choose the Right One for Your Needs

- How does the mechanical drive system of a Floating-Zone furnace impact crystal quality? Ensuring Homogeneity

- How is the furnace body of a vacuum furnace constructed? Explore Its Reinforced, Sealed Design for Extreme Conditions

- Why is a vacuum level of 5 to 10 Pa required for removing silicon and zinc from Rubidium Chloride? Expert Insights

- Why is temperature stability important in vacuum furnace operations? Ensure Precise Heat Treatment for Superior Materials

- What are the key indicators for measuring the performance of vacuum heat treatment equipment? Optimize Your Process with KINTEK

- What industries commonly use high vacuum furnaces? Unlock Purity and Strength for Critical Applications