A controlled environment is non-negotiable during the microwave sintering of Al2O3/TiC ceramics because Titanium Carbide (TiC) is extremely susceptible to oxidation at high temperatures. A high-purity nitrogen atmosphere or vacuum system effectively isolates the material from oxygen, preventing the hard TiC phase from degrading into titanium oxide.

The core purpose of these systems is to preserve the chemical integrity of the TiC phase. By preventing oxidation and removing adsorbed gases, the protective atmosphere ensures the ceramic maintains the extreme hardness and high density required for industrial performance.

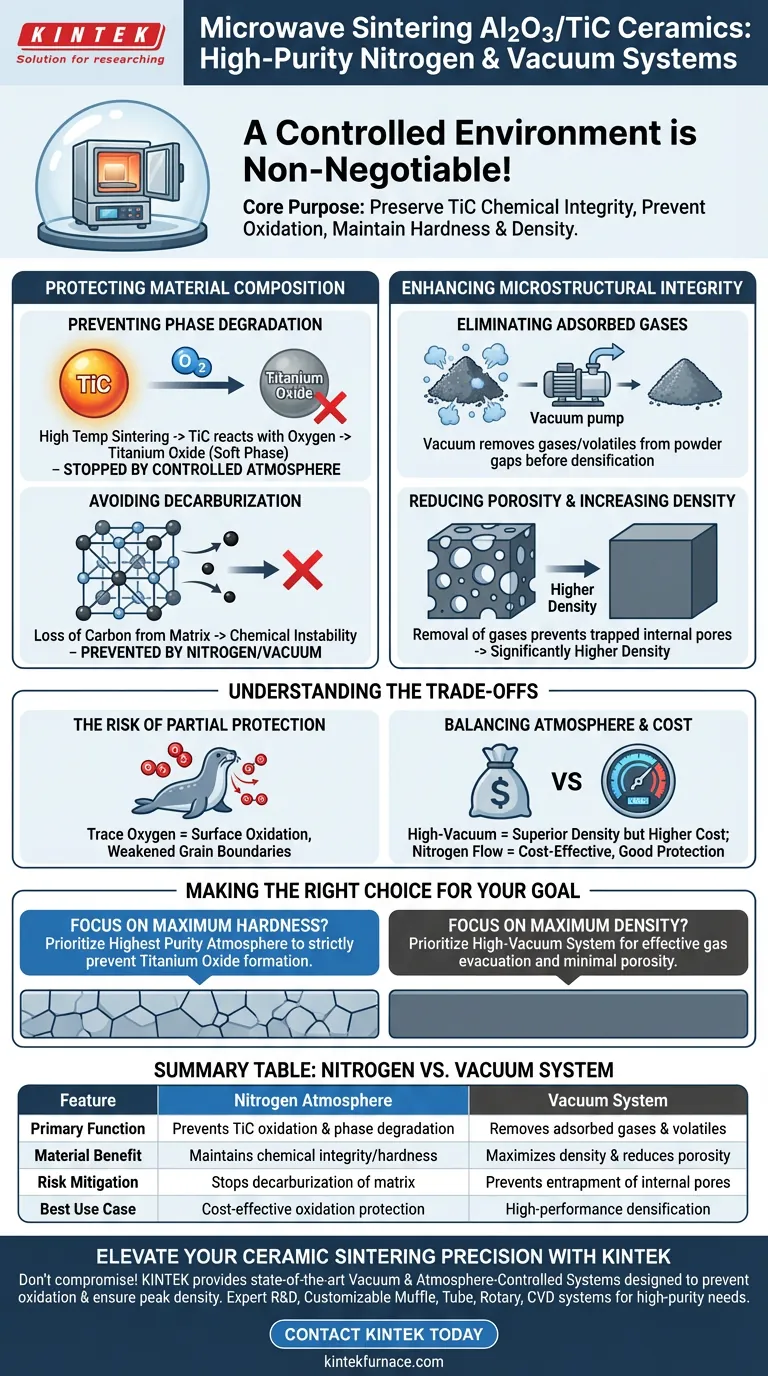

Protecting Material Composition

Preventing Phase Degradation

The primary danger during sintering is the chemical alteration of Titanium Carbide (TiC).

At the elevated temperatures required for sintering, TiC reacts aggressively with oxygen. Without a protective barrier, TiC oxidizes into titanium oxide.

This phase transformation is catastrophic for the material, as it destroys the specific "hard phase" that gives the ceramic its cutting ability and durability.

Avoiding Decarburization

Beyond simple oxidation, a lack of protection can lead to decarburization.

This process involves the loss of carbon atoms from the material matrix.

A vacuum or nitrogen environment prevents this loss, ensuring the chemical stability of the composite remains intact throughout the heating cycle.

Enhancing Microstructural Integrity

Eliminating Adsorbed Gases

Ceramic powders naturally hold onto gases and volatile impurities on their surfaces.

A vacuum system is particularly effective at extracting these adsorbed gases from the powder gaps before the material densifies.

Reducing Porosity and Increasing Density

If these gases are not removed, they become trapped inside the material as it hardens.

This entrapment creates internal pores, which weaken the structure.

By evacuating these impurities, the system promotes a significantly higher density and reduces the porosity of the final sintered body.

Understanding the Trade-offs

The Risk of Partial Protection

It is a common pitfall to assume that a "mostly" sealed environment is sufficient.

Even trace amounts of residual oxygen or low-purity nitrogen can lead to surface oxidation or weakened grain boundaries.

Balancing Atmosphere and Cost

While high-vacuum systems offer superior gas removal for density, they add complexity and cost compared to nitrogen flow.

However, compromising on the atmosphere quality invariably compromises the mechanical properties—specifically hardness and toughness—of the final tool.

Making the Right Choice for Your Goal

To achieve the optimal performance from your Al2O3/TiC ceramics, consider your specific performance metrics:

- If your primary focus is maximum hardness: Prioritize a system with the highest purity atmosphere to strictly prevent the formation of softer titanium oxide phases.

- If your primary focus is maximum density: Prioritize a high-vacuum system to effectively evacuate adsorbed gases and minimize internal porosity.

By rigorously controlling the sintering atmosphere, you ensure the material transitions from a loose powder to a high-performance composite without sacrificing its essential chemical properties.

Summary Table:

| Feature | Nitrogen Atmosphere | Vacuum System |

|---|---|---|

| Primary Function | Prevents TiC oxidation & phase degradation | Removes adsorbed gases & volatiles |

| Material Benefit | Maintains chemical integrity/hardness | Maximizes density & reduces porosity |

| Risk Mitigation | Stops decarburization of the matrix | Prevents entrapment of internal pores |

| Best Use Case | Cost-effective oxidation protection | High-performance densification |

Elevate Your Ceramic Sintering Precision with KINTEK

Don't compromise the integrity of your Al2O3/TiC composites. KINTEK provides state-of-the-art Vacuum and Atmosphere-Controlled Systems specifically engineered to prevent oxidation and ensure peak material density.

Backed by expert R&D and specialized manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, and CVD systems, all fully customizable to meet your unique laboratory or industrial high-temperature needs. Whether you require high-purity nitrogen flow or superior vacuum depth, our equipment guarantees the chemical stability your materials demand.

Contact KINTEK today to discuss your custom furnace solution and achieve the ultimate hardness and toughness for your advanced ceramics.

Visual Guide

References

- Samadar S. Majeed. Formulating Eco-Friendly Foamed Mortar by Incorporating Sawdust Ash as a Partial Cement Replacement. DOI: 10.3390/su16072612

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- What information does TG-DTG provide for AASC? Analyze Thermal Stability and Hydration Products

- What is the function of high-purity nitrogen (N2) during the heating phase of magnetite oxidation? Protect Your Data.

- How do h-BN targets improve memristor switching ratios? Maximize Logic Windows with High-Purity Precursors

- What role does quartz sand filler play in a crystal growth furnace? Enhance Thermal Symmetry and Yield

- What are the main types of sintering furnaces? Find the Perfect Match for Your Materials

- What is the catalytic mechanism of methane gas conversion in Ni-Co CNT synthesis? Master Carbon Transformation

- Why is the vacuum drying process essential for the synthesis of phthalonitrile-modified titanium dioxide? Expert Guide

- What is the role of high-purity helium in electromagnetic levitation? Key for Rapid Thermal Regulation