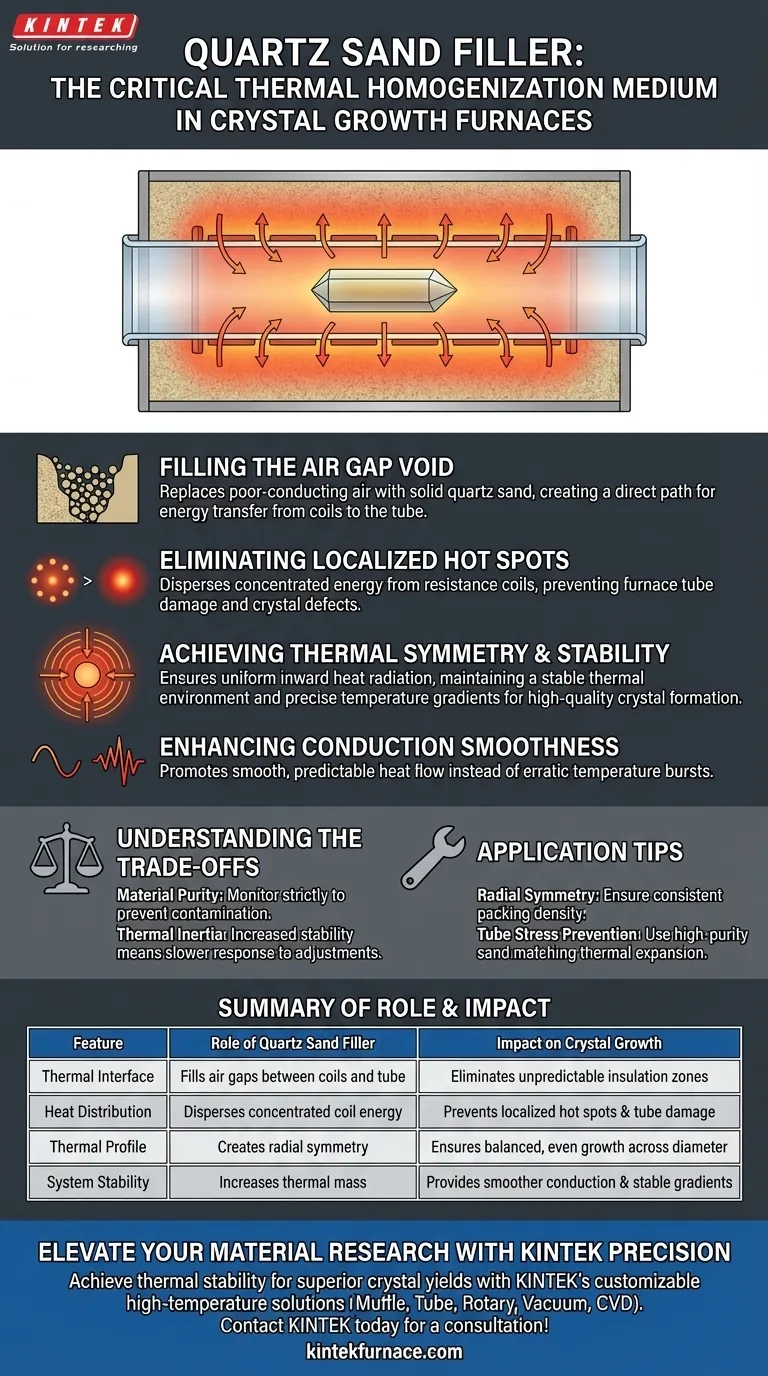

Quartz sand filler acts as a critical thermal homogenization medium. It bridges the air gaps between resistance heating coils and the furnace tube wall to eliminate localized hot spots. This physical interface ensures that heat is conducted smoothly and uniformly, resulting in the highly symmetrical radial heat distribution required for successful crystal growth.

Quartz sand serves as a conductive bridge that transforms erratic, localized heat from coils into a uniform thermal field. This stabilization is essential for maintaining the precise temperature gradients necessary for high-quality crystal formation.

The Role of Physical Interface in Heat Transfer

Filling the Air Gap Void

Air is a poor conductor of heat and can create unpredictable insulation zones within a furnace. By filling these gaps with quartz sand, the system creates a solid path for energy to move directly from the element to the tube.

Eliminating Localized Hot Spots

Resistance coils naturally generate intense heat at specific points along their physical length. The sand medium disperses this concentrated energy, preventing "hot spots" that could otherwise damage the furnace tube or cause structural defects in the growing crystal.

Achieving Thermal Symmetry and Stability

Establishing Radial Uniformity

Successful crystal growth requires a consistent temperature across the entire diameter of the growth zone. The sand ensures that heat radiates inward evenly from all sides of the furnace wall, maintaining a balanced thermal environment.

Enhancing Conduction Smoothness

Instead of rapid, jagged fluctuations in temperature, the sand allows for smoother heat conduction. This leads to a more predictable thermal environment where heat flows steadily through the medium rather than in erratic bursts.

Understanding the Trade-offs

Material Purity and Contamination

While quartz sand is an effective medium, its purity levels must be strictly monitored. Impurities within the sand can potentially migrate at high temperatures, leading to the degradation of the furnace components or contamination of the growth environment.

Thermal Inertia and Response Times

Adding a solid filler significantly increases the thermal mass of the furnace. While this improves stability, it also means the system will respond more slowly to manual temperature adjustments or programmed cooling cycles.

How to Apply This to Your Furnace Setup

Effective use of quartz sand filler requires a balance between thermal stability and the need for system responsiveness.

- If your primary focus is radial symmetry: Ensure the sand is packed with consistent density around the entire circumference to prevent lopsided heat distribution.

- If your primary focus is preventing tube stress: Use high-purity quartz sand to match the thermal expansion characteristics of the quartz furnace tube and minimize mechanical strain.

By effectively managing the interface between heating elements and the furnace tube, you establish the stable thermal foundation necessary for superior crystal yield.

Summary Table:

| Feature | Role of Quartz Sand Filler | Impact on Crystal Growth |

|---|---|---|

| Thermal Interface | Fills air gaps between coils and tube | Eliminates unpredictable insulation zones |

| Heat Distribution | Disperses concentrated coil energy | Prevents localized hot spots and tube damage |

| Thermal Profile | Creates radial symmetry | Ensures balanced, even growth across diameter |

| System Stability | Increases thermal mass | Provides smoother conduction and stable gradients |

Elevate Your Material Research with KINTEK Precision

Achieve the thermal stability required for superior crystal yields with KINTEK’s industry-leading high-temperature solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your specific research needs. Whether you require precise thermal homogenization or specialized furnace configurations, our team is ready to deliver the performance your lab demands.

Ready to optimize your thermal processes? Contact KINTEK today for a custom consultation!

Visual Guide

References

- Hua Wei, Hui Feng. Growth of 4-Inch InP Single-Crystal Wafer Using the VGF-VB Technique. DOI: 10.1021/acsomega.4c09376

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the function of a forced drying oven in SiOC coating conversion? Ensure Flawless Solvent Removal

- What is the significance of using an Annealing Furnace in gas sensors? Enhance Stability and Sensitivity

- What is the benefit of accessing furnace technical guides? Optimize Your Research with Precise Equipment Data

- What is the significance of using PVD for phosphosulfide thin films? Scale Your Optoelectronic Research to Industry

- What is the function of a precise heating system during the hydrolysis of palm kernel oil? Optimize Your Fatty Acid Yield

- How does a Rapid Thermal Processing (RTP) system function? Optimize Nanowire Device Performance Today

- How do industrial furnaces and quenching tanks affect TiCp/Fe composites? Optimize Heat Treatment Performance

- How is a vacuum impregnation system utilized during wood leaching resistance tests? Achieve Full Saturation for EN 84