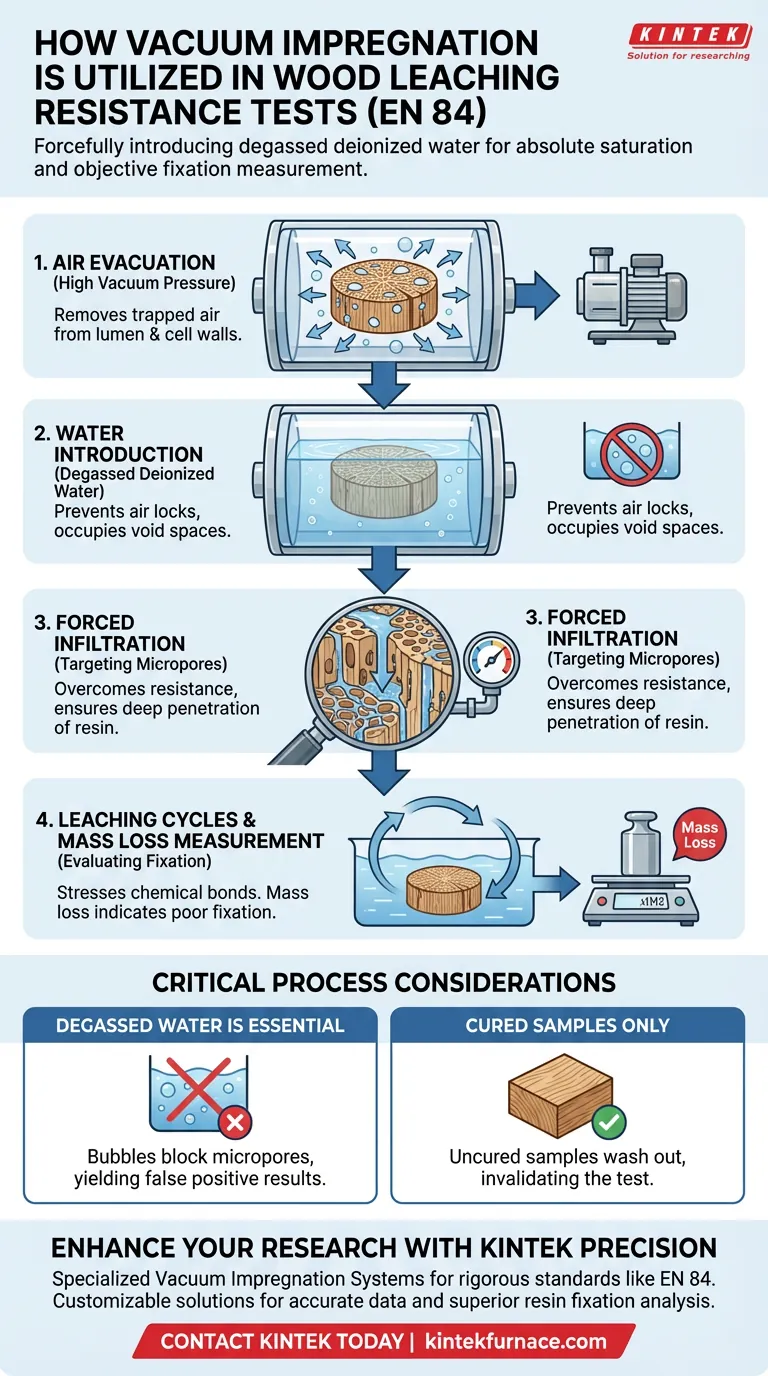

In wood leaching resistance tests, a vacuum impregnation system is utilized to forcefully introduce degassed deionized water into the cellular structure of cured, modified wood samples. This mechanical process uses high vacuum pressure to evacuate air from the wood's pores, allowing water to penetrate and completely fill the micropores, thereby simulating extreme moisture saturation.

The core objective of vacuum impregnation is to ensure absolute saturation. By eliminating air pockets, the system exposes the internal bonding of the resin to water, allowing for an accurate, objective measurement of fixation quality based on subsequent mass loss.

The Mechanics of Infiltration

Displacing Air with Water

The primary function of the vacuum system is to overcome the natural resistance of wood to rapid saturation. Wood contains air within its cellular lumen and cell walls.

The system creates a high-vacuum environment that evacuates this trapped air. Once the air is removed, degassed deionized water is introduced, occupying the void spaces previously filled by gas.

Targeting the Micropores

Standard soaking methods often fail to penetrate the smallest structures of the wood. Vacuum impregnation ensures that water reaches the micropores.

This deep penetration is essential for testing modified wood, as the modification agents (resins) often reside deep within these micro-structures.

Evaluating Resin Fixation

Simulating Extreme Conditions

The process is designed to mimic the most severe moisture conditions a wood product might encounter in its lifecycle.

By forcing water into every available pore, the test stresses the chemical and physical bonds between the wood and the modifying resin.

Measuring Bonding Strength

The ultimate metric for this test is mass loss.

Once the wood is fully impregnated, it undergoes water exchange cycles. If the resin is not properly fixed or bonded within the wood structure, the water will leach it out.

Because the vacuum ensured total contact between water and resin, any reduction in mass can be attributed to poor fixation rather than incomplete wetting.

Critical Process Considerations

The Importance of Degassed Water

The primary reference specifically highlights the use of degassed water. This is a critical variable.

If the water contains dissolved gases, bubbles can form when the vacuum is applied. These bubbles block the micropores, preventing full saturation and potentially yielding false positive results regarding the wood's leaching resistance.

Evaluating Cured Samples Only

This process is applicable specifically to cured wood samples.

Attempting to impregnate uncured samples would likely wash out the modification agent immediately, rather than testing its long-term resistance to leaching.

Ensuring Accurate Test Protocols

To effectively utilize a vacuum impregnation system for standards like EN 84, align your approach with your specific testing goals:

- If your primary focus is Resin Formulation: Analyze the mass loss data strictly after the water exchange cycles to determine the chemical bonding efficiency of your specific resin.

- If your primary focus is Test Validity: Verify that the water used is fully deionized and degassed to prevent air locks from protecting the resin from water contact.

Complete saturation is the only way to distinguish between a waterproof coating and a truly leach-resistant modification.

Summary Table:

| Process Step | Mechanism | Objective in EN 84 Testing |

|---|---|---|

| Air Evacuation | High vacuum pressure | Removes trapped air from cellular lumen and cell walls. |

| Water Introduction | Degassed deionized water | Prevents air locks and fills micropores completely. |

| Forced Infiltration | Pressure differential | Overcomes natural resistance to simulate extreme saturation. |

| Leaching Cycles | Periodic water exchange | Stresses chemical bonds to measure resin fixation via mass loss. |

Enhance Your Research with KINTEK Precision

Ensure your wood modification and leaching resistance tests meet the most rigorous standards like EN 84. Backed by expert R&D and manufacturing, KINTEK offers specialized Vacuum Impregnation Systems, Muffle, Tube, and Vacuum furnaces—all fully customizable to your unique laboratory needs.

Our advanced systems provide the precise control required to eliminate variables like dissolved gases and incomplete saturation, allowing you to focus on accurate data and superior resin fixation analysis.

Ready to elevate your lab's testing capabilities? Contact KINTEK today to discuss your custom solution.

Visual Guide

References

- Johannes Karthäuser, Holger Militz. Utilizing pyrolysis cleavage products from softwood kraft lignin as a substitute for phenol in phenol-formaldehyde resins for modifying different wood species. DOI: 10.1007/s00107-024-02056-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a temperature-controlled heating chamber ensure AEMWE testing accuracy? Unlock Reliable Electrolyzer Data

- Why is a constant temperature blast drying oven necessary for biomass carbon impregnation? Optimize Material Structure

- What is the function of ZrCp(NMe2)3? Master Precision Surface Passivation in Area-Selective ALD

- Why is an electric blast drying oven required for CRP microstructure analysis? Ensure Data Accuracy with Proper Drying

- What physical characteristics of high-precision heating equipment are used in CSE selenium recycling?

- How does a benchtop industrial oven improve efficiency? Boost Energy Savings and Space Use

- Why must catalysts undergo high-temperature pretreatment? Ensure Precise CO Oxidation Data with KINTEK

- Why is the use of silver-containing active brazing alloys prohibited in TEGs? Prevent Semiconductor Degradation