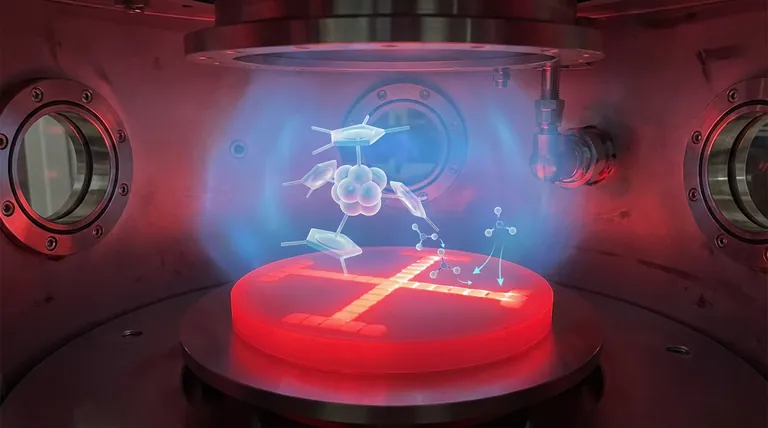

ZrCp(NMe2)3 functions as a highly specific, site-selective blocking agent within the Area-Selective Atomic Layer Deposition (AS-ALD) process. Acting as a secondary inhibitor, this heteroleptic precursor utilizes bulky cyclopentadienyl (Cp) ligands to physically shield crystalline facets on Zirconia surfaces, preventing the deposition of subsequent materials.

Core Insight: The utility of ZrCp(NMe2)3 lies in its ability to differentiate between surface morphologies on a chemically homogeneous material. By leveraging steric hindrance to passivate flat crystalline regions, it forces subsequent growth (specifically aluminum precursors) to occur only in desired areas, such as grain boundaries.

The Mechanism of Inhibition

To understand the efficacy of ZrCp(NMe2)3, one must look at how its molecular structure interacts with the substrate topology.

The Role of Heteroleptic Ligands

ZrCp(NMe2)3 is a heteroleptic precursor, meaning it contains different types of ligands.

The critical component here is the cyclopentadienyl (Cp) ligand. Unlike smaller ligands, the Cp group provides significant bulk, creating a physical barrier on the surface where the molecule adsorbs.

Steric Hindrance as a Shield

The primary mechanism of inhibition is steric hindrance.

When ZrCp(NMe2)3 adsorbs onto the surface, the bulky Cp ligands extend outward. This creates a crowded environment that physically blocks incoming aluminum precursors from reaching the reactive surface sites during subsequent ALD cycles.

Chemical Deactivation

Beyond physical blocking, the precursor modifies the chemical activity of the surface.

The Cp ligands possess lower chemical activity compared to the underlying substrate. Once adsorbed, they effectively "cap" the reactive sites, rendering them inert to the specific chemistry used in the following deposition step.

Achieving Selectivity on Homogeneous Surfaces

The unique value of this inhibitor is its ability to perform Area-Selective ALD on a surface that is chemically uniform (Zirconia) but morphologically diverse.

Targeting Crystalline Facets

ZrCp(NMe2)3 displays a distinct preference for adsorption on non-grain boundary regions, specifically the flat crystalline facets of the Zirconia (ZrO2) surface.

It does not readily adsorb into the grain boundaries. This selective adsorption creates a mask that covers the bulk of the crystalline grains while leaving the boundaries exposed.

Blocking Aluminum Nucleation

The ultimate function of this masking is to inhibit the growth of aluminum precursors.

Because the crystalline facets are shielded by the Cp ligands, the aluminum precursor cannot nucleate or grow there. Consequently, aluminum deposition is forced to occur exclusively in the unblocked grain boundary regions.

Understanding the Trade-offs

While effective, the use of ZrCp(NMe2)3 as a secondary inhibitor introduces specific constraints that must be managed.

Strict Morphological Dependence

The selectivity of this inhibitor is driven by surface morphology (facets vs. boundaries), not just surface chemistry.

If the Zirconia surface lacks well-defined crystalline facets or distinct grain boundaries, the selectivity of the inhibitor may degrade, leading to unwanted deposition on the grains or incomplete coverage.

Specificity to Aluminum Precursors

The reference highlights the blocking of aluminum precursors.

The steric protection provided by the Cp ligands is calibrated to specific molecular sizes and reactivities. It may not be equally effective against smaller or more aggressive precursors from different material families.

Making the Right Choice for Your Goal

To effectively utilize ZrCp(NMe2)3 in your AS-ALD process, align your objectives with its specific capabilities.

- If your primary focus is Grain Boundary Decoration: Rely on ZrCp(NMe2)3 to effectively passivate the bulk crystalline grains, forcing deposition solely into the grain boundaries.

- If your primary focus is Preventing Nucleation on Facets: Ensure your Zirconia surface has high crystallinity, as the inhibitor targets these specific non-grain boundary regions for adsorption.

Success with ZrCp(NMe2)3 depends on leveraging its bulky ligands to turn minor morphological differences into major barriers against chemical growth.

Summary Table:

| Feature | Description |

|---|---|

| Chemical Role | Heteroleptic Secondary Inhibitor |

| Active Mechanism | Steric Hindrance & Chemical Deactivation |

| Selective Target | Crystalline facets of Zirconia (ZrO2) |

| Key Ligand | Bulky Cyclopentadienyl (Cp) group |

| Primary Function | Blocks aluminum nucleation on grains to force growth in boundaries |

Elevate Your Material Research with KINTEK

Precise surface engineering requires high-performance equipment that can handle sophisticated chemical processes. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are customizable to meet your unique AS-ALD and high-temperature research needs.

Ready to achieve superior selectivity in your deposition processes? Contact us today to consult with our technical specialists and find the perfect system for your laboratory.

References

- Moo‐Yong Rhee, Il‐Kwon Oh. Area‐Selective Atomic Layer Deposition on Homogeneous Substrate for Next‐Generation Electronic Devices. DOI: 10.1002/advs.202414483

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

People Also Ask

- What role does a high-frequency LCR meter play in analyzing the CIS of SSBSN ceramics? Unlocking Microstructural Secrets

- What is the purpose of using a laboratory oven during sugarcane bagasse ash preparation? Optimize Material Pretreatment

- What are the technical advantages of using vacuum-assisted impregnation for 3D LIG/polymer composites? Boost Strength

- Why is it necessary for sintering equipment to have a high-cooling-rate control for 17-4 PH? Master Your Metallurgy

- What is the role of a high-temperature reaction furnace in flame fusion? Master Alumina Spheroidization

- What is the function of the nitrogen source in biomass pyrolysis? Optimize Bio-Oil Yield and Ensure Process Safety

- What is the role of a fixed-bed reactor in the slow pyrolysis process? Engineering High-Quality Biochar Production

- Why is immediate water quenching required for CuAlMn alloys? Master Phase Retention in Shape Memory Alloys