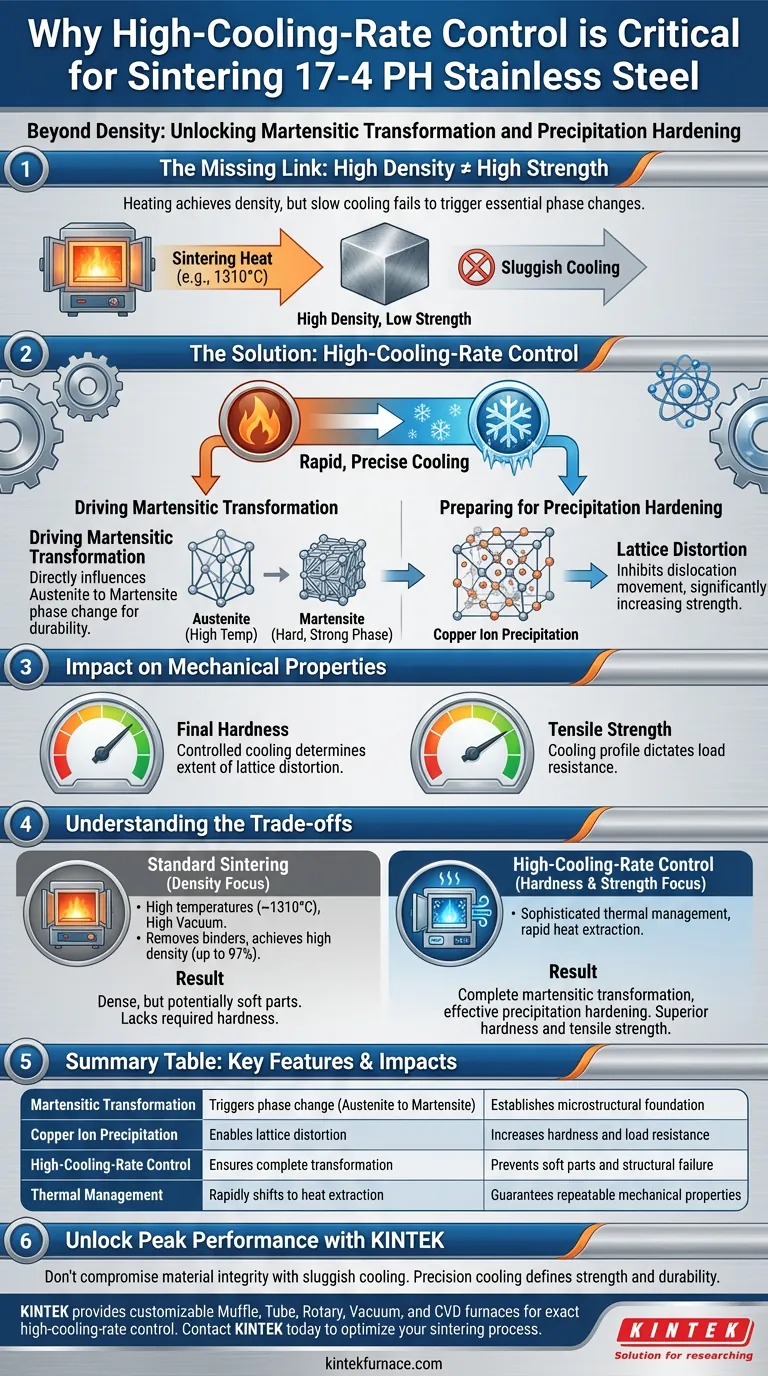

The necessity of a high-cooling-rate control function in sintering equipment is dictated by the specific metallurgical requirements of 17-4 PH stainless steel. While heating achieves density, precise and rapid cooling is required to drive the martensitic transformation, which is the fundamental phase change that gives this alloy its name and characteristics. Without this controlled cooling, you cannot establish the necessary microstructural foundation—specifically the lattice distortion caused by copper ion precipitation—which ultimately determines the final hardness and tensile strength of the part.

Core Takeaway Achieving high density through heat is only half the battle; the cooling curve is the "genetic switch" for 17-4 PH steel. Precise cooling rates are required to trigger the martensitic transformation and enable the copper-based precipitation hardening that defines the alloy's mechanical performance.

The Critical Role of Cooling in Metallurgy

Driving the Martensitic Transformation

17-4 PH is a precipitation-hardening alloy. Its mechanical properties do not come solely from the sintering heat, but from the phase change that occurs as the material returns to room temperature.

The cooling rate directly influences the transformation from austenite (the high-temperature phase) to martensite (the hard, strong phase). If the equipment lacks the ability to control this rate effectively, the transformation may be incomplete, resulting in a finished part that lacks the expected durability.

Preparing for Precipitation Hardening

The cooling phase lays the groundwork for subsequent heat treatments. The primary goal is to establish a specific microstructure that supports precipitation hardening.

During this process, the equipment must ensure the metal matrix is prepared for copper ion precipitation. This precipitation causes lattice distortion within the metal's atomic structure. It is this distortion that inhibits dislocation movement, thereby significantly increasing the material's strength.

Impact on Final Mechanical Properties

Determining Final Hardness

The relationship between the cooling curve and the end product is causal. The precision of the cooling rate determines the extent of the lattice distortion described above.

Consequently, the equipment's cooling capability acts as a primary control variable for the final hardness of the component. A sluggish or uncontrolled cooling cycle will inevitably lead to softer parts that fail to meet specifications.

Defining Tensile Strength

Tensile strength shares the same dependency on the cooling profile. The microstructural integrity established during cooling dictates how much load the material can withstand before failure.

To achieve the superior mechanical properties typical of 17-4 PH, the sintering furnace must be capable of adhering to a strict cooling profile that optimizes the metal's internal stress and structure.

Understanding the Trade-offs

Density vs. Mechanical Performance

It is critical to distinguish between densification and hardening. As noted in standard industrial processes, high-vacuum environments and high temperatures (e.g., 1310°C) are excellent for removing binders and achieving high densities (up to 97%).

However, a dense part is not necessarily a strong part. You may successfully sinter a part to near-theoretical density using standard heating, but without the high-cooling-rate control, that dense part will lack the specific mechanical properties (hardness and strength) required for high-performance applications.

Equipment Complexity

Implementing high-cooling-rate control increases the complexity of the sintering furnace. It requires sophisticated thermal management systems capable of shifting rapidly from high-heat maintenance to aggressive heat extraction.

While this increases the initial investment in equipment, it eliminates the risk of producing batches that meet dimensional and density checks but fail destructively in structural applications.

Making the Right Choice for Your Project

The selection of sintering equipment should be based on the specific performance metrics required by your final application.

- If your primary focus is geometric integrity and density: Standard vacuum sintering (reaching ~1310°C) is sufficient to remove binders and achieve high density, but it may not yield maximum hardness.

- If your primary focus is high hardness and tensile strength: You must prioritize equipment with active high-cooling-rate control to ensure complete martensitic transformation and effective copper ion precipitation.

Mastering the cooling curve is the non-negotiable final step in unlocking the full performance potential of 17-4 PH stainless steel.

Summary Table:

| Feature | Importance for 17-4 PH Sintering | Impact on Final Product |

|---|---|---|

| Martensitic Transformation | Triggers phase change from austenite to martensite | Establishes microstructural foundation |

| Copper Ion Precipitation | Enables lattice distortion within metal matrix | Increases hardness and load resistance |

| High-Cooling-Rate Control | Ensures complete transformation and grain control | Prevents soft parts and structural failure |

| Thermal Management | Rapidly shifts from 1310°C to heat extraction | Guarantees repeatable mechanical properties |

Unlock Peak Performance for Your 17-4 PH Components

Don't let a sluggish cooling cycle compromise your material integrity. Achieving high density is only the first step—precision cooling is what defines your part's strength and durability.

KINTEK provides industry-leading sintering solutions backed by expert R&D and manufacturing. Our systems, including Muffle, Tube, Rotary, Vacuum, and CVD furnaces, are fully customizable to provide the exact high-cooling-rate control required for your unique metallurgical needs.

Contact KINTEK today to discover how our specialized high-temperature lab furnaces can optimize your sintering process and ensure your 17-4 PH parts meet the highest performance standards.

Visual Guide

References

- Development of 17-4 PH Stainless Steel for Low-Power Selective Laser Sintering. DOI: 10.3390/ma18020447

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is XPS used to analyze manganese catalysts? Master Surface Valence States for Enhanced Reactivity

- How does a constant temperature and humidity curing chamber contribute to alkali-activated material performance?

- How is temperature regulated in laboratory furnaces? Master Precision Control for Reliable Results

- Why is a nitrogen (N2) purging system necessary for biomass torrefaction? Prevent Combustion and Maximize Biochar Yield

- Why must high-purity nitrogen be used for biochar activation? Ensure Carbon Integrity and Pore Development

- How does high-temperature substrate heating at 500 °C facilitate TiO2 formation? Enhance Film Density and Quality

- What role does a reactive atmosphere like nitrogen play in PFS? Enhance Titanium Dioxide Surface Treatment

- Why is the drying step using an industrial electric oven critical in catalyst preparation? Ensure Structural Integrity