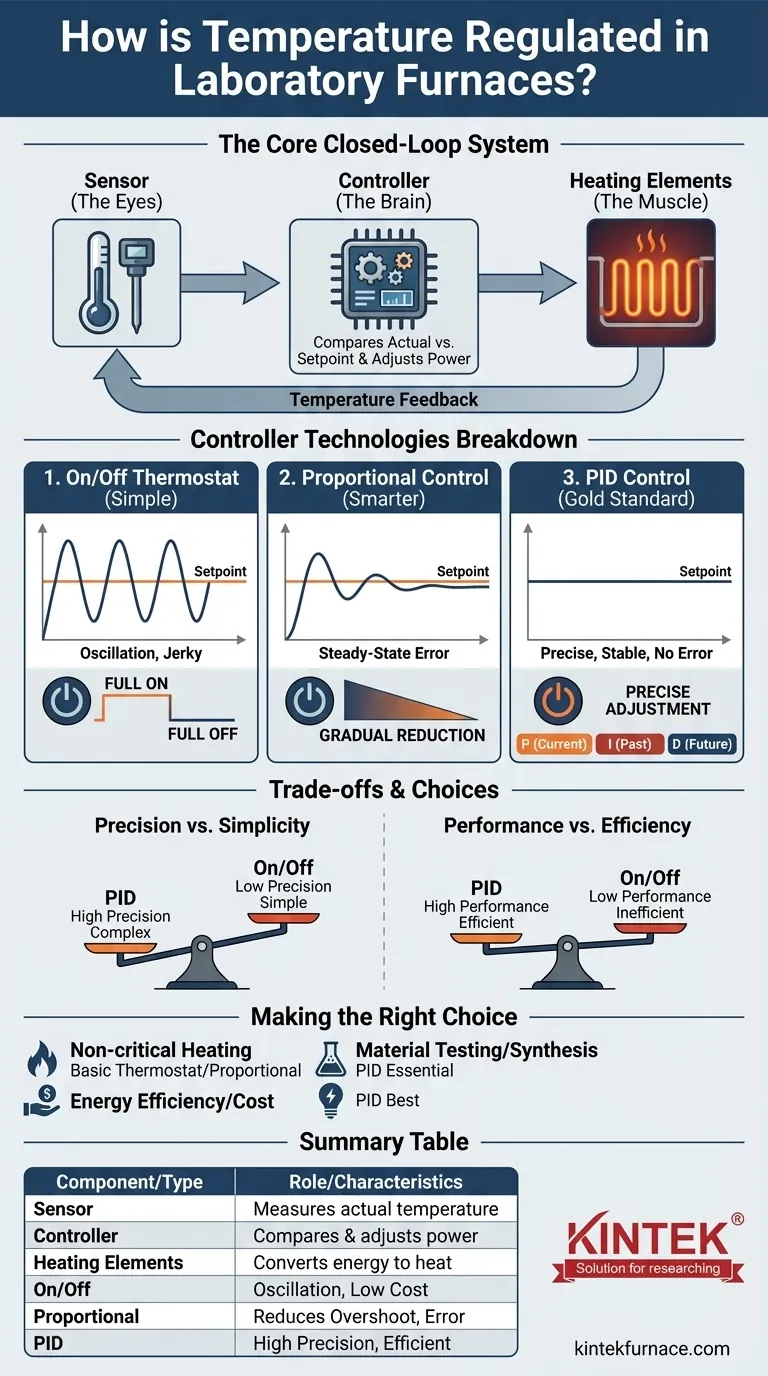

At its core, laboratory furnace temperature is regulated by a closed-loop control system. This system uses a temperature sensor to measure the internal heat, a controller to decide what to do, and heating elements to apply the energy. The sophistication of the controller is what dictates the furnace's precision and stability.

The method of temperature control is the single most important factor determining a laboratory furnace's performance. While simple on/off thermostats exist, modern scientific applications demand advanced PID controllers to achieve the necessary accuracy, stability, and repeatability for valid results.

The Core Components of Temperature Regulation

To understand how a furnace maintains a set temperature, you must first recognize its three essential components working in a constant feedback loop.

The Sensor: The Eyes of the System

A temperature sensor, typically a thermocouple, is placed inside the furnace chamber. Its sole job is to continuously measure the actual temperature and report this data back to the controller.

The Controller: The Brain of the Operation

The controller is the decision-making unit. It constantly compares the actual temperature (from the sensor) to the desired temperature (the setpoint you entered). Based on the difference, it calculates how much power to send to the heating elements.

The Heating Elements: The Muscle

These are the components that convert electrical energy into heat. The controller tells them when to turn on, how much power to use, and when to turn off, thereby directly managing the heat inside the furnace.

A Breakdown of Controller Technologies

The "intelligence" of the controller determines how tightly the temperature can be managed. There are three primary levels of control technology.

The Thermostat: Simple On/Off Control

This is the most basic form of regulation. If the temperature is below the setpoint, the controller sends full power to the heating elements. Once it reaches the setpoint, it cuts all power.

This method inevitably leads to a temperature oscillation, constantly overshooting and undershooting the target. It's like a driver who only uses either the full accelerator or the full brake, resulting in a jerky ride.

Proportional Control: A Smarter Approach

A proportional controller is more nuanced. As the furnace temperature gets closer to the setpoint, the controller gradually reduces the power supplied to the heating elements.

This "easing off the gas" action significantly dampens the temperature overshoot seen with a simple thermostat. However, it often results in a small but persistent steady-state error, where the temperature stabilizes just slightly below the setpoint.

PID Control: The Gold Standard for Precision

PID (Proportional-Integral-Derivative) control is the most advanced and common method in modern laboratory furnaces. It uses a sophisticated algorithm to maintain exceptionally stable temperatures.

- Proportional (P): Acts based on the current temperature error, just like a proportional controller.

- Integral (I): Looks at past errors. It calculates the accumulated offset over time and adjusts the power to eliminate the steady-state error, ensuring the furnace reaches the exact setpoint.

- Derivative (D): Predicts future errors. It monitors the rate of temperature change and adjusts power to proactively prevent overshoot before it happens.

This three-part calculation allows the controller to make incredibly precise adjustments, resulting in fast, stable, and highly repeatable thermal cycles.

Understanding the Trade-offs

Choosing a furnace involves balancing cost, complexity, and the precision required for your work. The control method is central to this trade-off.

Precision vs. Simplicity

A simple on/off thermostat is inexpensive and easy to implement, but it offers the lowest level of precision. It is only suitable for applications where a general temperature range is acceptable.

PID controllers are algorithmically complex and require careful tuning but deliver the highest degree of accuracy, holding temperatures to within a fraction of a degree.

Performance vs. Energy Efficiency

The constant on/off cycling of a thermostat is inefficient, as is the energy wasted by significant temperature overshooting.

By calculating the exact amount of energy needed to hold a stable temperature, PID control is the most energy-efficient method. It avoids wasteful power spikes and maintains temperature with minimal energy input.

Making the Right Choice for Your Application

The control system you need is dictated entirely by the demands of your work.

- If your primary focus is non-critical heating or drying: A furnace with simple thermostat or basic proportional control may be sufficient and more cost-effective.

- If your primary focus is material testing, chemical synthesis, or any process requiring high repeatability: A furnace with a well-tuned PID controller is essential for reliable and valid results.

- If your primary focus is energy efficiency and long-term operational cost: A PID controller offers the best performance, reducing wasted energy from temperature fluctuations.

Understanding the control method behind your furnace empowers you to select the right tool and ensure the integrity of your results.

Summary Table:

| Component | Role in Temperature Regulation |

|---|---|

| Sensor (e.g., Thermocouple) | Measures actual temperature inside the furnace chamber |

| Controller (e.g., PID) | Compares actual vs. setpoint temperature and adjusts power output |

| Heating Elements | Converts electrical energy to heat based on controller signals |

| Control Type | Key Characteristics |

| ----------- | -------------------------------- |

| On/Off Thermostat | Simple, low cost, causes temperature oscillation |

| Proportional Control | Reduces overshoot, may have steady-state error |

| PID Control | High precision, eliminates error, energy-efficient |

Need a high-temperature furnace with precise temperature control for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements for accuracy and efficiency. Contact us today to discuss how we can enhance your laboratory's performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure