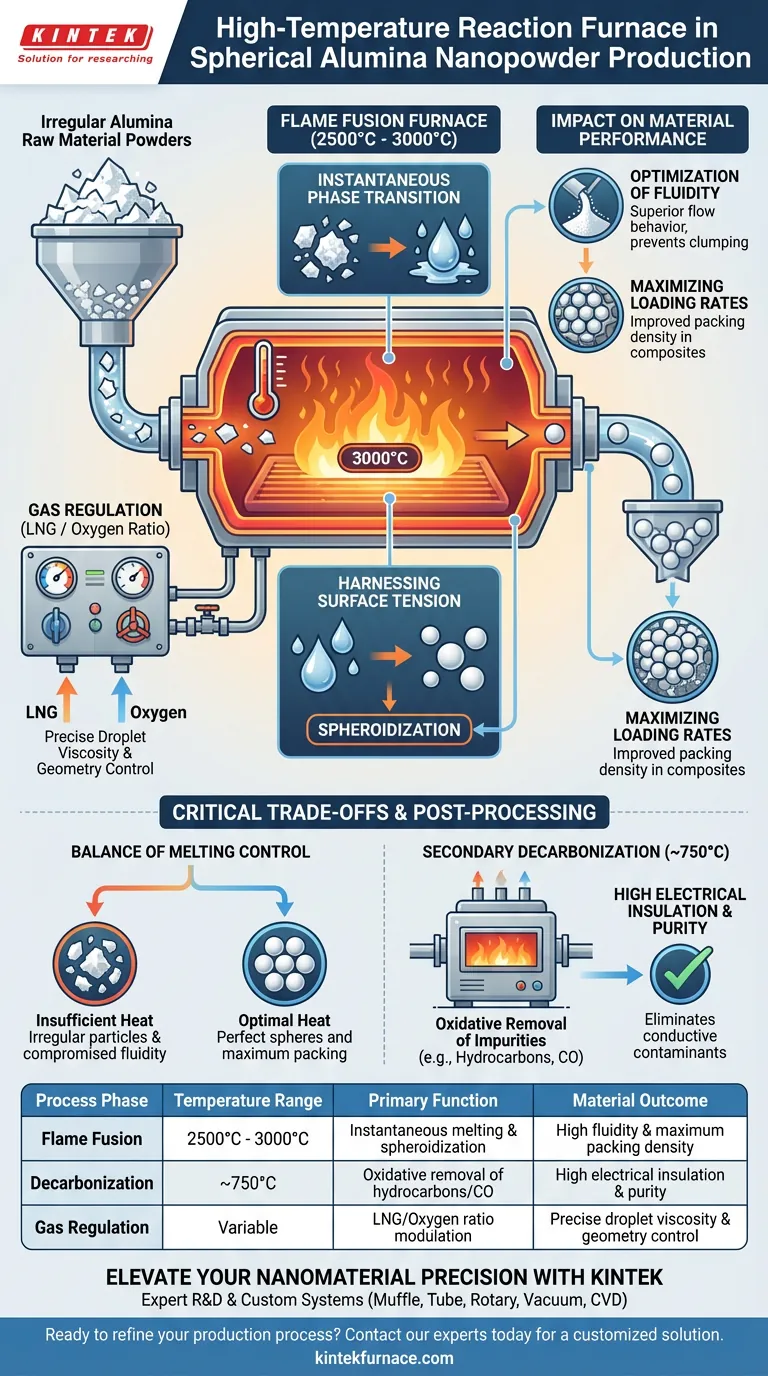

The high-temperature reaction furnace acts as the primary transformation vessel in the flame fusion process, responsible for the morphological change of the material. It generates an extreme thermal environment, specifically between 2500 and 3000 degrees Celsius, to instantaneously melt irregular alumina raw material powders into liquid droplets.

The furnace's core function is to facilitate rapid spheroidization through precise thermal management. By controlling the combustion atmosphere, the furnace dictates the surface tension of the molten droplets, which directly determines the particle geometry and the final material's ability to pack efficiently in composite applications.

The Mechanism of Spheroidization

Instantaneous Phase Transition

The fundamental role of the furnace is to overcome the high melting point of alumina.

By sustaining temperatures of 2500 to 3000 degrees Celsius, the furnace forces the raw powder to undergo an immediate phase transition from solid to liquid.

This rapid melting is critical to ensure that every particle becomes fully molten before it exits the thermal zone.

Harnessing Surface Tension

Once the alumina is liquefied, physics takes over.

The furnace environment allows the liquid droplets to naturally pull themselves into perfect spheres due to surface tension.

This transformation from irregular, jagged particles to smooth spheres is the defining value add of the flame fusion process.

Controlling the Melt via Gas Ratios

The furnace is not just a heat source; it is a tunable reaction chamber.

Operators adjust the flow rate ratio of liquefied natural gas (LNG) and oxygen to modulate the flame characteristics.

This precise control regulates the degree of powder melting, ensuring the droplets have the correct viscosity and surface tension to circularize effectively.

Impact on Material Performance

Optimization of Fluidity

The spherical shape produced in the furnace drastically changes how the powder behaves in bulk.

Spherical powders exhibit superior fluidity, allowing them to flow like a liquid rather than clumping like jagged dust.

Maximizing Loading Rates

Because the particles are spherical, they can be packed more tightly together.

This improves the loading rate in composite materials, allowing manufacturers to fit more functional alumina into a given volume of resin or binder.

Critical Trade-offs and Post-Processing

The Balance of Melting Control

Achieving perfect spheres requires a delicate balance in the LNG/Oxygen ratio.

If the temperature or dwell time is insufficient, the powder will not fully melt, resulting in irregular shapes that compromise fluidity.

Conversely, aggressive thermal environments must be managed to maintain particle size distribution.

The Role of Secondary Decarbonization

While the fusion furnace operates at up to 3000°C to shape the particle, it does not necessarily remove all impurities.

A secondary high-temperature process, often performed at 750 degrees Celsius, is required for decarbonization.

This step utilizes oxidative reactions to remove adsorbed impurities like acetaldehyde, hydrocarbons, and carbon monoxide.

Without this secondary thermal treatment, residual carbon can create thermal resistance or unwanted conductive paths, undermining the electrical insulation properties of the final composite.

Making the Right Choice for Your Goal

To maximize the efficacy of your alumina nanopowder production, align your furnace parameters with your specific material requirements:

- If your primary focus is Physical Packing and Flow: Prioritize the precise control of the LNG/Oxygen ratio in the 2500–3000°C range to ensure maximum spheroidization and surface tension.

- If your primary focus is Electrical Insulation: Ensure your process includes a distinct decarbonization hold at 750°C to eliminate carbonaceous impurities that act as conductive contaminants.

The furnace is not merely a heater, but a precision tool for engineering particle geometry and surface chemistry simultaneously.

Summary Table:

| Process Phase | Temperature Range | Primary Function | Material Outcome |

|---|---|---|---|

| Flame Fusion | 2500°C - 3000°C | Instantaneous melting & spheroidization | High fluidity & maximum packing density |

| Decarbonization | ~750°C | Oxidative removal of hydrocarbons/CO | High electrical insulation & purity |

| Gas Regulation | Variable | LNG/Oxygen ratio modulation | Precise droplet viscosity & geometry control |

Elevate Your Nanomaterial Precision with KINTEK

Unlock superior material performance with advanced thermal engineering. Whether you are optimizing spherical alumina for high-loading composites or ensuring peak electrical insulation through precise decarbonization, KINTEK provides the expertise you need.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. All our lab high-temperature furnaces are fully customizable to meet the unique atmospheric and thermal demands of your specific application.

Ready to refine your production process? Contact our experts today to design a customized furnace solution that guarantees material excellence.

Visual Guide

References

- Seul-Ki Kim, Eun Young Jung. Fabrication and Characterization of Al2O3-Siloxane Composite Thermal Pads for Thermal Interface Materials. DOI: 10.3390/ma17040914

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a forced air drying oven essential after molding biomass briquettes? Enhance Fuel Quality & Strength

- Why is a high-pressure digestion tank essential for ZnO/rGO hydrothermal synthesis? Achieve superior interfacial coupling

- How does calcination temperature affect CuO grain growth? Optimize Nanoporous Film Morphology and Crystallinity

- How does Plasma Flash Sintering (PFS) equipment enable the stabilization of metastable phases? Defy Thermal Limits

- What are the primary advantages of using powder metallurgy for Ti and TiZr alloys? Achieve Ultimate Structural Precision

- What is the function of a laboratory vacuum drying oven when loading metal nanoparticles onto porous carbon particles?

- What is the function of a precision laboratory oven in KNN ceramic pretreatment? Ensure Stoichiometric Accuracy

- What is the function of aluminum foil in leather combustion experiments? Optimize Thermal Isolation and Accuracy