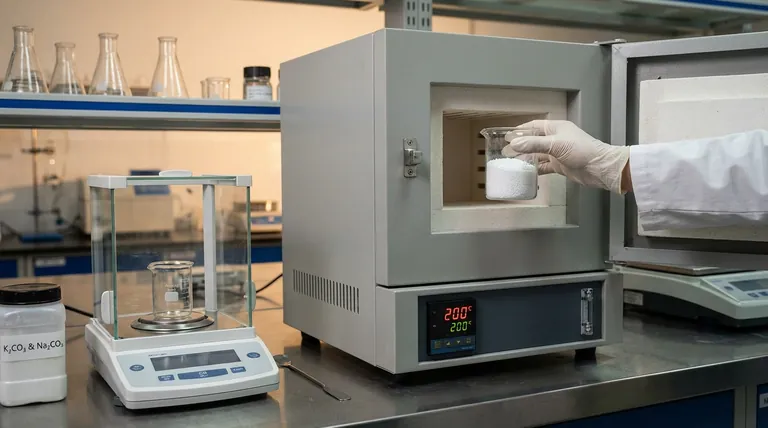

The primary function of a precision laboratory oven in the pretreatment of KNN-based ceramic raw materials is to neutralize the effects of hygroscopicity. Materials such as potassium carbonate and sodium carbonate naturally absorb moisture from the air, which alters their weight. The oven provides a controlled thermal environment to completely remove this adsorbed water prior to the critical weighing stage.

By maintaining a constant temperature of 200°C, the oven ensures that the raw materials are weighed based on their actual chemical mass rather than water weight. This step is the foundation for achieving the strict stoichiometric ratios required for high-performance piezoelectric ceramics.

The Challenge of Hygroscopic Raw Materials

The Nature of KNN Ingredients

In the production of Potassium Sodium Niobate (KNN) ceramics, key raw materials like potassium carbonate and sodium carbonate are highly hygroscopic.

This means they actively attract and hold water molecules from the surrounding environment.

The Weighing Discrepancy

If these materials are weighed without pretreatment, the measurement includes the weight of the adsorbed bound water.

This results in adding less actual reactive material than the formula requires, throwing off the chemical balance of the final ceramic.

The Role of Precision Heating

Removing Bound Water

The laboratory oven creates a stable environment, typically set to 200°C, to drive off moisture.

This temperature is sufficient to thoroughly remove adsorbed water without decomposing the carbonate raw materials themselves.

Ensuring Stoichiometric Precision

The ultimate goal of this drying process is to guarantee a strict stoichiometric ratio.

In solid-state reactions, the ratio of atoms must be exact. Even a slight deviation caused by moisture weight can degrade the piezoelectric properties of the final product.

Understanding the Critical Process Controls

Temperature Uniformity

While the target is 200°C, the precision of the oven is vital.

Fluctuations in temperature could result in incomplete drying or, conversely, uneven heating that affects the material's physical state.

Process Timing

The duration of heating must be sufficient to ensure the material reaches a steady, dry state.

Cutting this process short risks leaving residual moisture, reintroducing the weighing errors the process is meant to eliminate.

Making the Right Choice for Your Goal

If your primary focus is Formulation Accuracy: Ensure your oven is calibrated to maintain 200°C precisely, as this eliminates the moisture variable that distorts your chemical recipe.

If your primary focus is Material Performance: Prioritize this pretreatment step to guarantee the correct solid-state reaction, which is the prerequisite for high piezoelectric activity.

Precise environmental control during the raw material stage is the invisible variable that determines the success or failure of advanced ceramic engineering.

Summary Table:

| Process Step | Requirement | Purpose |

|---|---|---|

| Target Temperature | 200°C | Removes adsorbed water without decomposing carbonates |

| Material Focus | K₂CO₃ & Na₂CO₃ | Neutralizes high hygroscopicity of lead-free precursors |

| Control Priority | Thermal Uniformity | Prevents weighing discrepancies and ensures chemical balance |

| Final Outcome | Stoichiometric Precision | Foundation for high-performance piezoelectric activity |

Elevate Your Ceramic Engineering with KINTEK

Precision is the foundation of high-performance KNN ceramics. At KINTEK, we understand that even a minor weighing discrepancy can compromise your research. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside our precision laboratory ovens, all customizable to your unique pretreatment needs.

Don't let moisture compromise your stoichiometry. Ensure absolute consistency in your solid-state reactions with our industry-leading thermal solutions. Contact us today to find the perfect precision oven for your lab!

References

- Michaela Roudnická, Dalibor Vojtěch. Hydrogen Embrittlement of Ti-Al6-V4 Alloy Manufactured by Laser Powder Bed Fusion Induced by Electrochemical Charging. DOI: 10.3390/met14020251

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a drying oven with precise temperature control necessary for NiO-CGO anode supports? Ensure Cell Integrity

- Why is high-purity argon gas used to purge the furnace? Ensure Precision in TGA Oxidation Kinetic Tests

- How does a magnetic stirring hot plate contribute to sol-gel synthesis? Expert Guide to Precursor Thin Film Success

- What is the function of a laboratory vacuum drying oven when loading metal nanoparticles onto porous carbon particles?

- What is the role of mortar grinding combined with heat gun processing in catalyst synthesis? Achieving PtCln Dispersion

- What is the purpose of magnetron sputtering in N-I-P CsPbBr3 detectors? Optimize Charge Transport & Stability

- What are the advantages of using a vacuum oven for drying porous carbon? Protect Microstructures & Prevent Oxidation

- What are the advantages of using a fixed-bed flow reactor? Precision Tools for Ammonia Decomposition Catalytic Activity