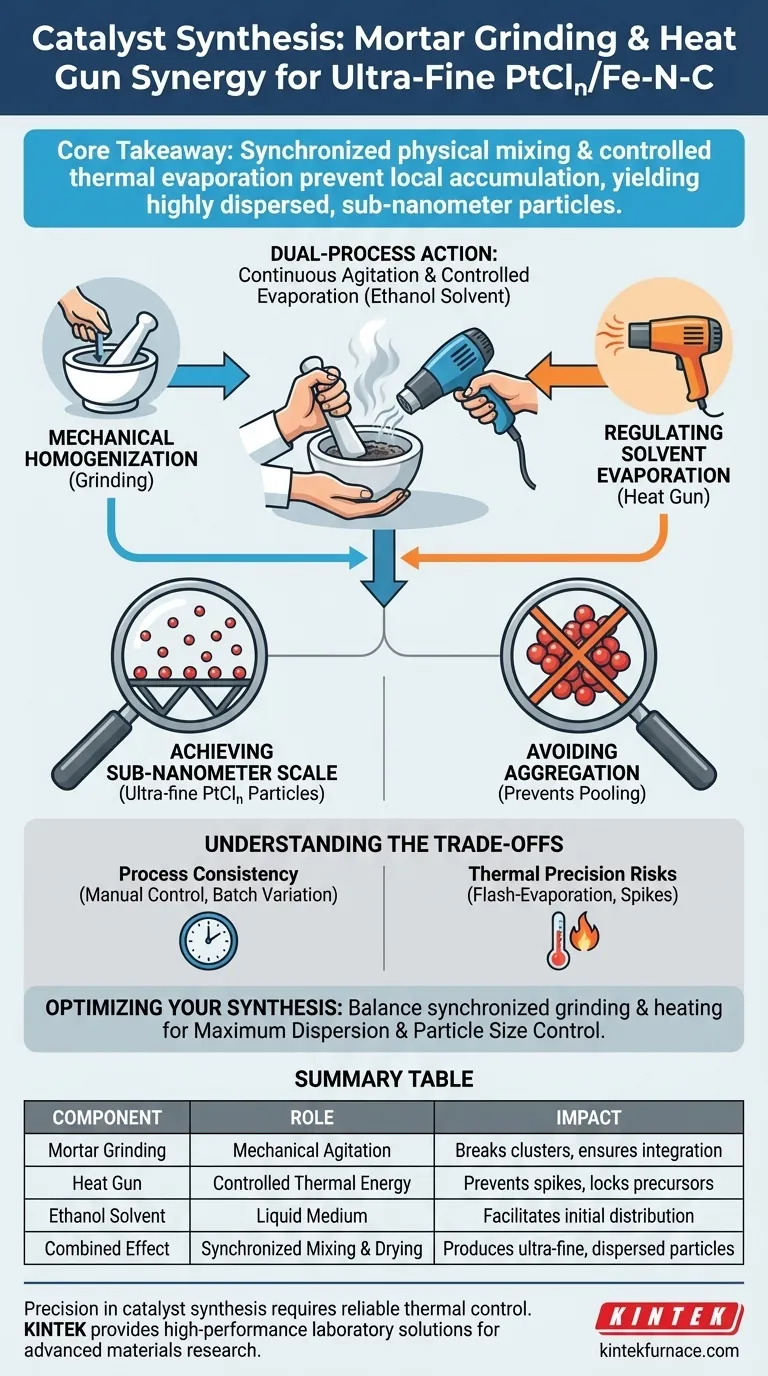

The combination of mortar grinding and heat gun processing serves as a critical regulation step to ensure the uniform distribution of platinum precursors on Fe-N-C supports. This manual technique synchronizes physical mixing with thermal evaporation control, specifically preventing local accumulation of chloroplatinic acid to yield ultra-fine, dispersed catalyst particles.

Core Takeaway By controlling the evaporation rate of ethanol while simultaneously agitating the mixture, this method prevents the formation of local concentration spikes. This precise regulation is the defining factor in achieving highly dispersed, sub-nanometer PtCln particles and avoiding precursor aggregation.

Mechanisms of Dispersion Control

Regulating Solvent Evaporation

The primary role of the heat gun in this synthesis is to provide controlled thermal energy to the ethanol solvent.

Without active thermal management, solvents may evaporate unevenly or too slowly, allowing time for precursors to migrate and pool.

The heat gun ensures the ethanol evaporates at a steady, manageable rate, locking the precursor in place as the liquid volume decreases.

Preventing Concentration Spikes

As solvents evaporate, dissolved solids naturally tend to precipitate out of the solution.

If this process is uncontrolled, it creates local concentration spikes, where the chloroplatinic acid gathers in dense clusters.

Continuous grinding combined with heat mitigates this risk by keeping the mixture dynamic until the solvent is removed, forcing a uniform spread rather than localized dumping.

Mechanical Homogenization

The mortar grinding provides the physical agitation necessary to expose the Fe-N-C support surfaces to the precursor solution continuously.

This ensures that the chloroplatinic acid does not just sit on top of the support but is physically integrated into the texture of the material.

The mechanical action breaks up potential clusters before they can solidify during the drying phase.

Impact on Catalyst Morphology

Achieving Sub-nanometer Scale

The ultimate goal of this dual-processing technique is to define the size of the final platinum species.

By preventing the precursor from pooling, the synthesis achieves ultra-fine PtCln particles.

These particles are maintained at the sub-nanometer scale, which is often critical for maximizing the active surface area of the catalyst.

Avoiding Aggregation

Aggregation is the enemy of catalyst efficiency, as it hides valuable platinum atoms inside the bulk of a particle.

This method specifically targets the liquid-phase stage to stop precursor aggregation before it starts.

The result is a highly dispersed material where the platinum is utilized efficiently across the support surface.

Understanding the Trade-offs

Process Consistency

Because this method relies on manual grinding, it introduces a variable of human control.

Unlike automated stirring, the uniformity of the grind depends on the operator's technique, which can lead to batch-to-batch variations if not strictly standardized.

Thermal Precision Risks

While the heat gun controls evaporation, incorrect distance or temperature settings can backfire.

If the heat is applied too aggressively, the solvent may flash-evaporate, potentially causing the very concentration spikes the process aims to prevent.

Success requires a balance where the evaporation is faster than natural drying but slow enough to allow thorough grinding.

Optimizing Your Synthesis Strategy

To maximize the effectiveness of your catalyst preparation, consider the following regarding your specific goals:

- If your primary focus is Maximum Dispersion: Prioritize the synchronization of grinding and heating to ensure no "wet spots" remain where precursors can aggregate.

- If your primary focus is Particle Size Control: Monitor the ethanol evaporation rate closely to prevent rapid drying, which locks in sub-nanometer dimensions.

The quality of your final catalyst depends entirely on how effectively you prevent the precursor from clustering during the critical transition from liquid to solid phase.

Summary Table:

| Process Component | Functional Role | Impact on Catalyst Morphology |

|---|---|---|

| Mortar Grinding | Mechanical homogenization & physical agitation | Breaks up clusters; ensures integration into support texture |

| Heat Gun | Controlled thermal energy & solvent evaporation | Prevents local concentration spikes; locks precursors in place |

| Ethanol Solvent | Liquid-phase medium | Facilitates initial distribution before controlled removal |

| Combined Effect | Synchronized mixing and drying | Produces ultra-fine, sub-nanometer, highly dispersed particles |

Precision in catalyst synthesis requires reliable thermal control. KINTEK provides high-performance laboratory solutions—including Muffle, Tube, and Vacuum furnaces—engineered to meet the rigorous demands of advanced materials research. Backed by expert R&D and manufacturing, our systems are fully customizable for your unique Fe-N-C or PtCln synthesis needs. Contact us today to optimize your laboratory workflow!

Visual Guide

References

- Hiroshi Yano. Sustainable activation of the PtCl <sub> <i>n</i> </sub> /Fe–N–C cathode for PEFCs through repeated subnanometer sizing and coarsening. DOI: 10.1039/d5lf00185d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why are varied heating rates applied during oil shale pyrolysis? Optimize Kinetics and Technical Validation

- Why is 500°C thermal stabilization necessary for titania supports? Ensure Catalyst Stability and Performance

- Why is argon gas preferred over other inert gases? Discover Its Optimal Balance for Industrial Use

- Why is a vacuum heating pretreatment system essential for zeolite characterization? Ensure Precise Pore Structure Data

- Why is 600 °C critical for ZIF-8 carbonization? Achieve Optimal Surface Area and Functional Group Retention

- Why is a standard constant temperature and humidity curing box used for magnesium slag mortar? Key Pre-treatment Facts

- What is Joule Heating and how does it relate to induction heating? Master the Physics of Contactless Heating

- What is the function of a laboratory vacuum drying oven in BAFPAE processing? Maintain Precursor Purity and Stability