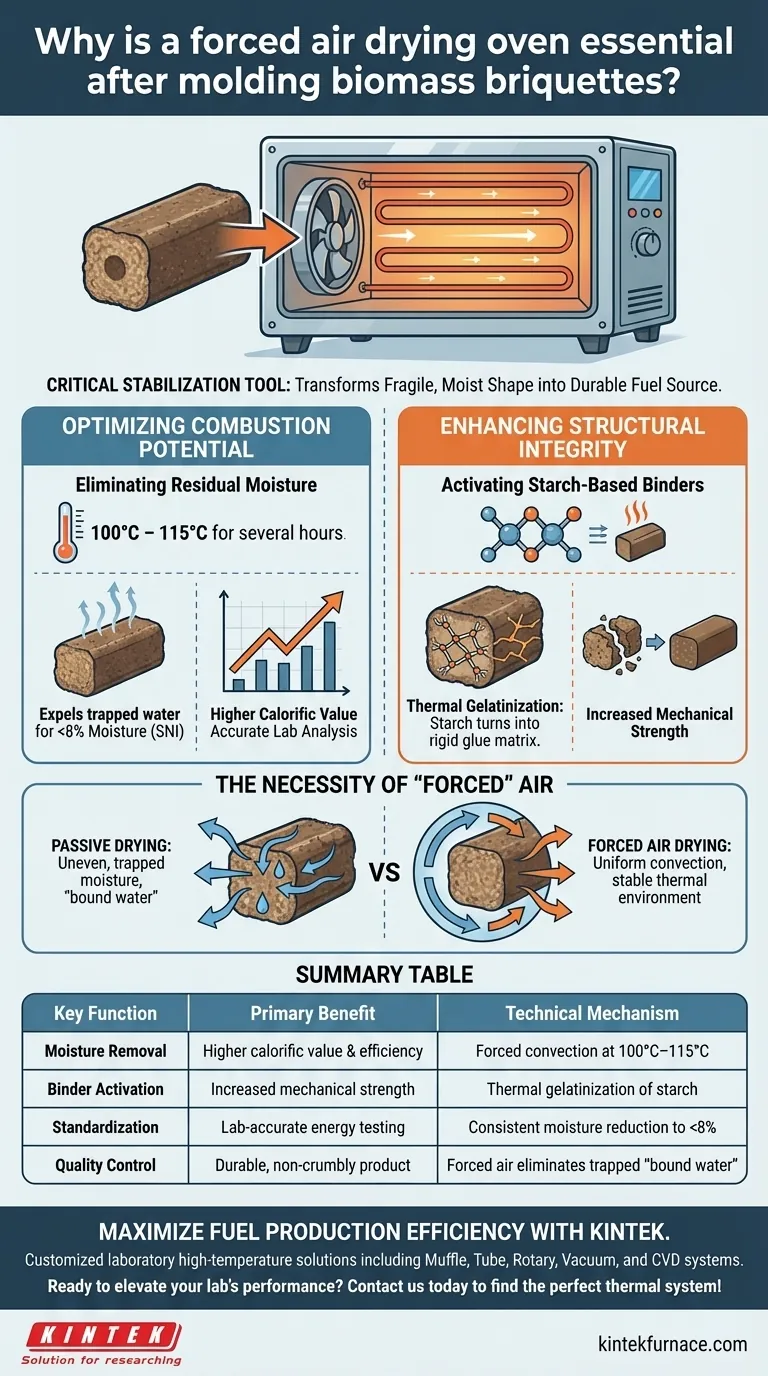

A forced air drying oven is the critical stabilization tool used immediately after biomass briquettes are molded. It performs the dual function of expelling deep-seated moisture to optimize combustion efficiency and thermally activating binders to solidify the briquette's physical structure.

The drying oven transforms a fragile, moist molded shape into a durable fuel source by simultaneously reducing water content to combustion standards and hardening the internal binders.

Optimizing Combustion Potential

Eliminating Residual Moisture

The primary function of the drying oven is the removal of moisture that remains trapped after the molding process. While mechanical molding exerts pressure, it cannot remove all water content.

The oven typically operates at temperatures between 100°C and 115°C for several hours to force this evaporation.

Ensuring Accurate Calorific Analysis

For laboratory applications, removing this moisture is mandatory for accurate testing. If moisture remains, it skews the measurement of the briquette's calorific value (the energy released during burning).

By expelling this water, the oven ensures the fuel meets specific standards, such as maintaining moisture levels below 8% (SNI). This directly translates to higher combustion efficiency in the final product.

Enhancing Structural Integrity

Activating Starch-Based Binders

Heat treatment is not just about drying; it is a chemical hardening process. Many briquettes utilize starch-based binders to hold the biomass particles together.

The heat from the oven causes these starches to undergo gelatinization.

Finalizing Mechanical Strength

As the starch gelatinizes and subsequently hardens, it acts as a rigid glue matrix throughout the briquette.

This process significantly enhances the mechanical strength of the finished product. Without this thermal hardening, the briquette would remain fragile and prone to crumbling during transport or handling.

Understanding the Trade-offs

The Necessity of "Forced" Air

You might ask if passive drying is sufficient. The "forced air" or "blast drying" mechanism is essential because static heat often leads to uneven drying.

Without the forced convection providing a stable thermal environment, moisture can remain trapped in the center of the briquette even if the outside feels dry. This results in "bound water" retention, which degrades the fuel's long-term stability and burn quality.

Making the Right Choice for Your Goal

To get the most out of your drying process, align your oven settings with your specific objectives:

- If your primary focus is Accurate Lab Analysis: Ensure the oven is set to expel all residual moisture to prevent water content from artificially lowering your calorific value readings.

- If your primary focus is Product Durability: Prioritize a heat cycle sufficient to fully gelatinize the binder, ensuring the briquettes are hard enough to withstand shipping and handling.

The drying oven is the bridge between a raw mixture and a high-performance fuel product.

Summary Table:

| Key Function | Primary Benefit | Technical Mechanism |

|---|---|---|

| Moisture Removal | Higher calorific value & efficiency | Forced convection at 100°C–115°C |

| Binder Activation | Increased mechanical strength | Thermal gelatinization of starch |

| Standardization | Lab-accurate energy testing | Consistent moisture reduction to <8% |

| Quality Control | Durable, non-crumbly product | Forced air eliminates trapped "bound water" |

Maximize Your Fuel Production Efficiency with KINTEK

Don’t let moisture compromise your fuel quality or structural integrity. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory high-temperature solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which can be customized to your specific biomass processing and analysis needs.

Whether you are refining calorific accuracy or hardening binders for shipping, our precision drying technologies provide the uniform heat control you require.

Ready to elevate your lab's performance? Contact us today to find the perfect thermal system for your unique application!

Visual Guide

References

- Mersi Suriani Sinaga, Dadi Oslar Sitinjak. Quality Analysis of Biobriquettes Combination Ratio of Oil palm Frond and Water Hyacinth Waste with Durian Seed Flour Adhesive. DOI: 10.9767/jcerp.20407

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is a vacuum heating pretreatment system essential for zeolite characterization? Ensure Precise Pore Structure Data

- Why is a vibratory mill used for ultra-fine grinding when preparing magnesite samples for zeta potential tests?

- How does high-temperature calcination affect kaolin? Boost Surface Area and Catalytic Reactivity via Thermal Processing

- Why is vacuum impregnation necessary for PAN-GF electrodes? Ensure Peak Fiber Conductivity and Slurry Integration

- What process problems are addressed by using a walking-beam furnace model? Solve Clad Plate Thermal Stress Challenges

- How does environmental control equipment assist in assessing CMS membranes? Unlock Precision in Physical Aging Tests

- What technical advantages do high-temperature furnace systems provide for robust flexible interconnects? Enhance Durability

- How do laboratory tablet presses ensure performance in iodine battery prototypes? Optimize Interfacial Contact Today