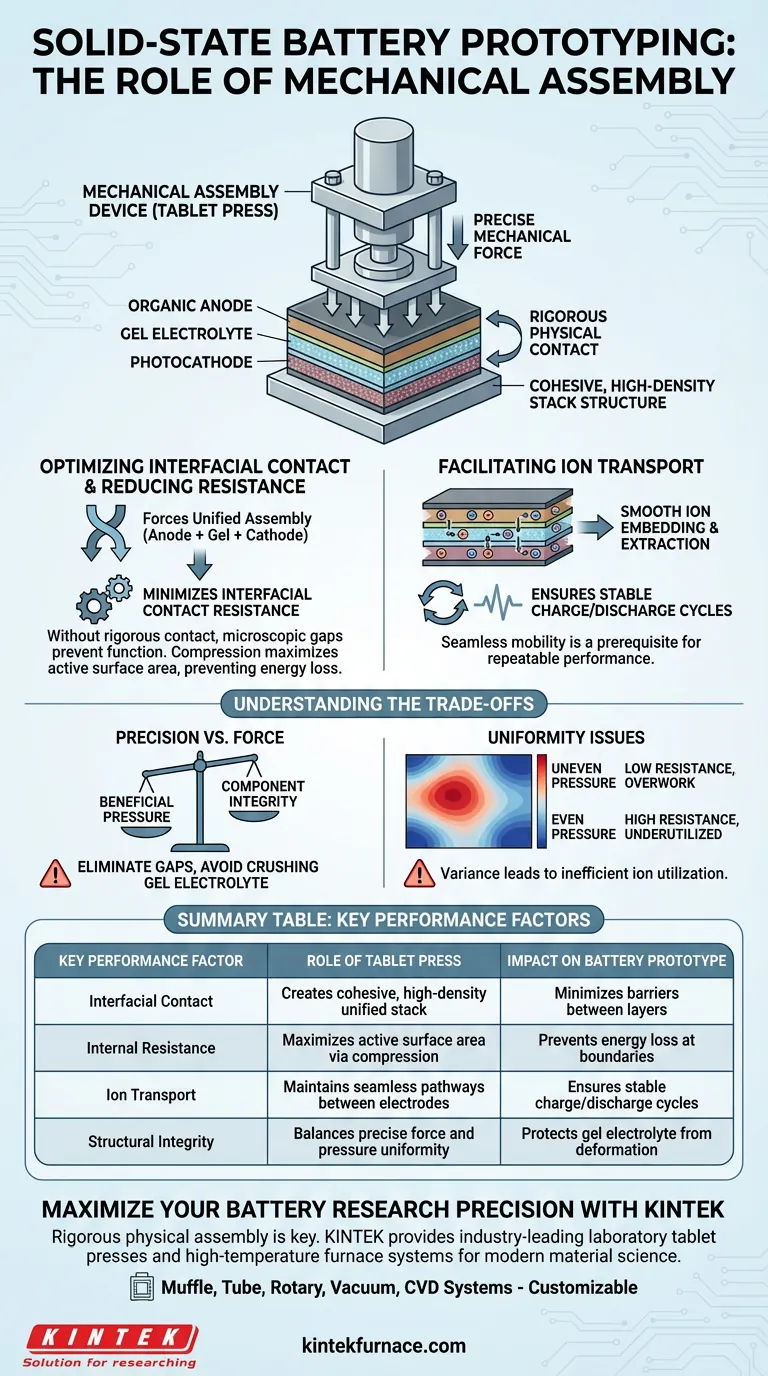

Laboratory tablet presses ensure performance by creating a cohesive, high-density stack structure. By applying precise mechanical force, these devices establish rigorous physical contact between the organic anode, the gel electrolyte, and the photocathode. This physical compression is the fundamental mechanism used to overcome interfacial barriers in solid-state prototypes.

The critical function of mechanical assembly is to minimize interfacial contact resistance. By enforcing a tight stack structure, the device ensures that ions can move freely between electrodes, which is essential for efficient charging and discharging.

The Mechanics of Prototype Assembly

Optimizing Interfacial Contact

In dual-ion solid-state iodine batteries, the physical boundaries between layers are the most vulnerable points for performance loss.

The tablet press forces the organic anode, gel electrolyte, and photocathode into a unified assembly.

Without this rigorous contact, microscopic gaps prevent the components from functioning as a single electrochemical system.

Reducing Internal Resistance

A loose or uneven assembly inherently results in high interfacial contact resistance.

Mechanical compression directly combats this by maximizing the active surface area where the layers touch.

By minimizing this resistance, the assembly ensures that energy is directed toward storage and release rather than being lost to poor connectivity.

Facilitating Ion Transport

The ultimate goal of the assembly process is to support the chemical cycle of the battery.

The tight stacked structure created by the press allows ions to smoothly embed and extract between the two electrodes.

This seamless mobility is a prerequisite for achieving stable and repeatable charging and discharging cycles.

Understanding the Trade-offs

Precision vs. Force

While rigorous contact is necessary, there is a limit to how much pressure is beneficial.

The mechanical device must apply enough force to eliminate gaps without crushing the delicate gel electrolyte or deforming the organic anode.

Successful assembly requires finding the exact balance where contact is maximized but component integrity is preserved.

Uniformity Issues

Mechanical assembly devices must ensure pressure is distributed evenly across the entire surface of the tablet.

If pressure is applied unevenly, it creates localized areas of low resistance and other areas of high resistance.

This variance can lead to inefficient ion utilization, causing parts of the battery to overwork while others remain underutilized.

Making the Right Choice for Your Assembly Process

To ensure reliable data from your dual-ion solid-state iodine prototypes, consider these priorities:

- If your primary focus is Cycle Stability: Prioritize a press setting that guarantees a "tight stacked structure" to maintain ion pathways over repeated charging cycles.

- If your primary focus is Efficiency: Ensure your assembly minimizes "interfacial contact resistance" to prevent energy loss at the layer boundaries.

Ultimately, the performance of your solid-state prototype relies as much on the physical quality of the assembly as it does on the chemistry of the components.

Summary Table:

| Key Performance Factor | Role of Tablet Press in Assembly | Impact on Battery Prototype |

|---|---|---|

| Interfacial Contact | Creates a cohesive, high-density unified stack | Minimizes barriers between layers |

| Internal Resistance | Maximizes active surface area via compression | Prevents energy loss at boundaries |

| Ion Transport | Maintains seamless pathways between electrodes | Ensures stable charge/discharge cycles |

| Structural Integrity | Balances precise force and pressure uniformity | Protects gel electrolyte from deformation |

Maximize Your Battery Research Precision with KINTEK

High-performance solid-state battery prototypes require more than just chemistry; they demand rigorous physical assembly. KINTEK provides industry-leading laboratory tablet presses and high-temperature furnace systems designed to meet the exacting standards of modern material science.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your unique research needs. Whether you are focusing on minimizing interfacial resistance or ensuring long-term cycle stability, our equipment ensures your components function as a single, efficient electrochemical system.

Ready to elevate your lab's performance? Contact us today to discuss your custom furnace and assembly needs!

Visual Guide

References

- Solar Trap‐Adsorption Photocathode for Highly Stable 2.4 V Dual‐Ion Solid‐State Iodine Batteries. DOI: 10.1002/adma.202504492

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the advantages of using a vacuum oven for drying porous carbon? Protect Microstructures & Prevent Oxidation

- How does the secondary calcination process improve Na2WO4-loaded catalysts? Optimize Surface Performance Today

- What is the primary role of a ball mill in raw material preparation for vacuum carbothermic reduction of magnesium? Ensure a Complete and Rapid Reaction

- How does a vacuum environment influence the accuracy of thermoelectric performance measurements for TaAs2? Ensure Precision in Your Research

- How does industrial-scale forging equipment influence the morphology of primary carbonitrides in H13 tool steel?

- How does the use of a stainless steel high-pressure autoclave affect ZnS/CeO2@CNT formation? Optimize Catalyst Growth

- Why is annealing in a heat treatment furnace performed on graphite flake/copper composite samples before performance testing? Ensure Data Integrity for Precision Thermal Expansion Measurements

- What reaction conditions are provided by stirring and heating equipment? Optimize Non-Aqueous Sol-Gel Synthesis