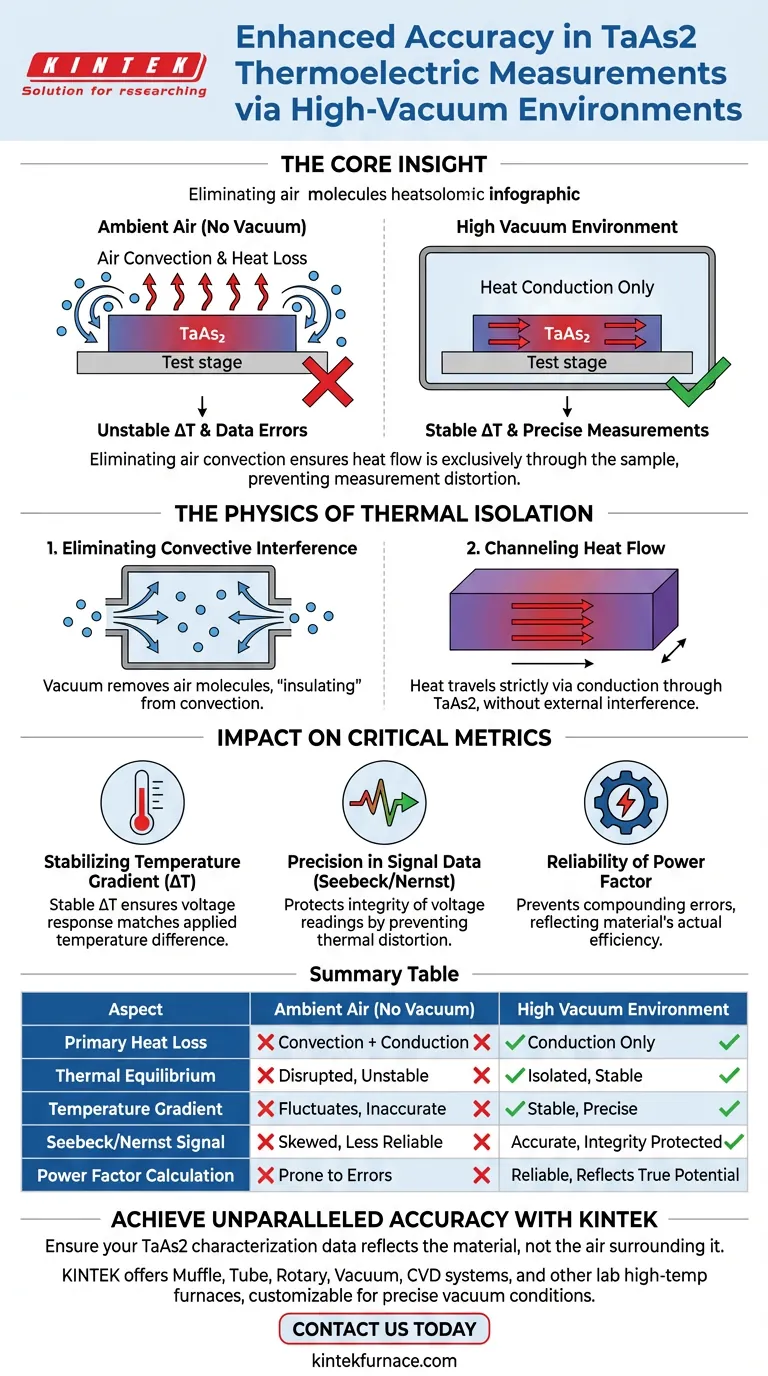

A high-vacuum environment significantly enhances measurement accuracy for TaAs2 by eliminating heat loss due to air convection. By removing air from the testing chamber, you ensure that heat transfer occurs exclusively via conduction through the sample material, which is critical for establishing the stable temperature gradient necessary for precise Seebeck coefficient and Nernst signal readings.

The Core Insight Thermoelectric precision relies on the isolation of heat flow. A vacuum environment removes the variable of convective cooling, ensuring that the temperature difference measured across the sample is a result of intrinsic material properties, not environmental airflow, preventing downstream errors in power factor calculations.

The Physics of Thermal Isolation

Eliminating Convective Interference

In an ambient air environment, air molecules carry heat away from the sample surface.

This process, known as air convection, disrupts the thermal equilibrium. A vacuum environment removes these molecules, effectively "insulating" the experiment from convective heat loss.

Channeling Heat Flow

Once convection is eliminated, the path of heat transfer changes.

Heat is forced to travel strictly via conduction through the sample itself. This isolation is mandatory for characterizing the true thermal transport properties of TaAs2 without external interference.

Impact on Critical Metrics

Stabilizing the Temperature Gradient

Accurate thermoelectric measurement requires a known, fixed temperature difference ($\Delta T$) across the material.

Air currents cause fluctuations in this gradient. A vacuum stabilizes $\Delta T$, ensuring the voltage response you measure corresponds exactly to the applied temperature difference.

Precision in Signal Data

The Seebeck coefficient and Nernst signal are voltage responses to thermal gradients.

If the thermal gradient is distorted by air cooling, the resulting voltage data will be skewed. Vacuum conditions protect the integrity of these specific signal measurements.

Reliability of Power Factor Calculations

The power factor is a derived metric calculated from the Seebeck coefficient and electrical conductivity.

Because a vacuum prevents errors in the initial Seebeck measurement, it prevents those errors from compounding. This ensures the final power factor calculation reflects the material's actual efficiency potential.

Understanding the Trade-offs

The Risk of "Parasitic" Heat Loss

Without a high vacuum, you face the issue of parasitic heat channels.

Air convection acts as an invisible heat sink. If you measure TaAs2 in air, you may overestimate the thermal conductivity or underestimate the temperature gradient, leading to invalid characterization.

Sensitivity to Pressure Changes

Partial vacuums can be deceptively inaccurate.

If the vacuum level is insufficient, even a small amount of residual gas can induce convection effects. The environment must be a high vacuum to fully negate these convective errors.

Making the Right Choice for Your Goal

To ensure your TaAs2 characterization is valid, align your experimental setup with your precision requirements.

- If your primary focus is determining the Seebeck Coefficient: Ensure your vacuum system is robust enough to eliminate all convective cooling, or your voltage/temperature ratio will be incorrect.

- If your primary focus is calculating Power Factor: Prioritize the stability of your thermal gradient; any fluctuation in $\Delta T$ due to air will render your efficiency calculations void.

By controlling the environment, you ensure that the data reflects the material, not the air surrounding it.

Summary Table:

| Aspect | Ambient Air (No Vacuum) | High Vacuum Environment |

|---|---|---|

| Primary Heat Loss | Convection + Conduction | Conduction Only |

| Thermal Equilibrium | Disrupted, Unstable | Isolated, Stable |

| Temperature Gradient | Fluctuates, Inaccurate | Stable, Precise |

| Seebeck/Nernst Signal | Skewed, Less Reliable | Accurate, Integrity Protected |

| Power Factor Calculation | Prone to Errors | Reliable, Reflects True Potential |

Achieve unparalleled accuracy in your thermoelectric material characterization. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs. Our advanced furnace solutions ensure the precise vacuum conditions vital for reliable TaAs2 measurements and beyond. Elevate your research with KINTEK's precision technology—contact us today to discuss your specific requirements and optimize your experimental setup!

Visual Guide

References

- Haiyao Hu, Claudia Felser. Multipocket synergy towards high thermoelectric performance in topological semimetal TaAs2. DOI: 10.1038/s41467-024-55490-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is shrinkage in the context of high-temperature materials? Master Dimensional Control for Stronger Parts

- Why are DEZ and GEME selected for Ge:ZnO ALD? Unlock Precise Atomic Doping and Thermal Stability

- What are the advantages of using a nitrate salt bath furnace? Superior Quenching for Sorbitic Steel Wire

- How does a vacuum oven contribute to the performance of composite electrode slurries? Enhance Battery Life & Stability

- What are the primary applications of a constant temperature drying oven? Master Biochar Selenium-Modification

- Why is a Rapid Thermal Processing (RTP) furnace necessary for diode fabrication? Achieve Stable Ohmic Contacts

- What are the advantages of using a microwave reaction system? Rapid & Uniform Synthesis of Doped Hydroxyapatite

- How do the process parameters of stir casting equipment influence the wear resistance of aluminum matrix composites?