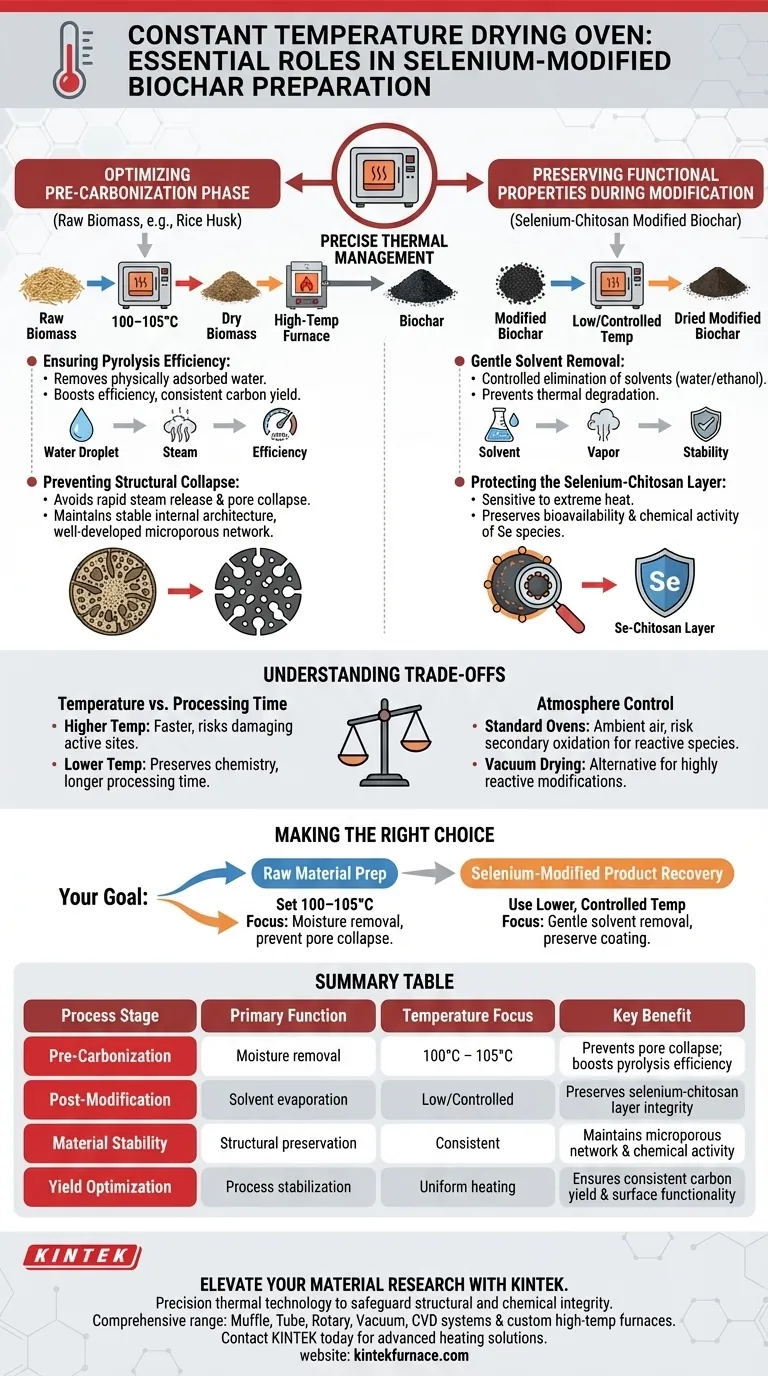

Precise thermal management is the critical function of a constant temperature drying oven during biochar production. In the context of selenium-modification, this equipment serves two distinct but equally vital roles: removing moisture from raw materials to ensure efficient carbonization, and gently eliminating solvents from the final product to preserve delicate surface chemistry.

The constant temperature drying oven acts as a process stabilizer—it safeguards the physical structure of the raw biomass before pyrolysis and protects the chemical functionality of the selenium-modified surface after synthesis.

Optimizing the Pre-Carbonization Phase

Ensuring Pyrolysis Efficiency

Before the biomass (such as rice husk) enters the high-temperature furnace, it must be thoroughly dried. The constant temperature oven removes physically adsorbed water from the raw material.

Eliminating this moisture ensures that energy during the subsequent carbonization step is utilized for thermal decomposition rather than water evaporation. This leads to higher pyrolysis efficiency and a more consistent carbon yield.

Preventing Structural Collapse

While the primary goal is moisture removal, the implications for the material's structure are profound. If moisture remains inside the biomass, rapid heating during pyrolysis can cause flash vaporization.

This rapid release of steam can exert pressure on the internal matrix, leading to an irregular collapse of the pore structure. By using a drying oven (typically around 100°C to 105°C) beforehand, you ensure the internal architecture remains stable, setting the stage for a well-developed microporous network.

Preserving Functional Properties During Modification

Gentle Solvent Removal

Following the selenium-chitosan modification process, the biochar is typically saturated with residual solvents, such as water or ethanol. These must be removed to finalize the product.

The constant temperature drying oven allows for the controlled elimination of these liquids. Unlike high-heat methods, this process is conducted at relatively low temperatures, which is essential for the stability of the new coating.

Protecting the Selenium-Chitosan Layer

The most critical risk at this stage is thermal degradation. The functional properties of the selenium-chitosan layer are sensitive to extreme heat.

By utilizing a constant temperature environment, you prevent the degradation of the modified surface layer. This ensures that the bioavailability and chemical activity of the selenium species are maintained in the final biochar product.

Understanding the Trade-offs

Temperature vs. Processing Time

There is an inherent tension between drying speed and material integrity. Increasing the temperature accelerates solvent removal but risks damaging the active sites on the modified biochar.

Conversely, setting the temperature too low preserves the chemistry but significantly extends processing time. This can create bottlenecks in production, especially when treating materials with high porosity that trap solvents deep within their structure.

Atmosphere Control

Standard constant temperature ovens generally operate under ambient atmospheric conditions. While effective for removing moisture, they may not prevent secondary oxidation if the modification involves highly reactive species (like certain metal oxides).

In such sensitive cases, a standard oven may allow aggregation of particles or unwanted surface reactions. For highly reactive modifications, a vacuum drying environment might be a necessary alternative to a standard constant temperature oven.

Making the Right Choice for Your Goal

To maximize the effectiveness of your drying oven, align your settings with your specific process stage:

- If your primary focus is Raw Material Preparation: Set the oven to 100–105°C to prioritize the complete removal of physically adsorbed water and prevent pore collapse during pyrolysis.

- If your primary focus is Selenium-Modified Product Recovery: Use a lower, controlled temperature to gently remove ethanol or water without degrading the functional chitosan-selenium surface layer.

Success lies in treating the drying oven not just as a heater, but as a precision tool for structural and chemical preservation.

Summary Table:

| Process Stage | Primary Function | Temperature Focus | Key Benefit |

|---|---|---|---|

| Pre-Carbonization | Moisture removal | 100°C - 105°C | Prevents pore collapse; boosts pyrolysis efficiency |

| Post-Modification | Solvent evaporation | Low/Controlled | Preserves selenium-chitosan layer integrity |

| Material Stability | Structural preservation | Consistent | Maintains microporous network & chemical activity |

| Yield Optimization | Process stabilization | Uniform heating | Ensures consistent carbon yield & surface functionality |

Elevate Your Material Research with KINTEK

Precision is the foundation of high-performance biochar and selenium-modification. KINTEK provides the industry-leading thermal technology required to safeguard your material's structural and chemical integrity. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temp furnaces—all fully customizable to meet your unique research or production needs.

Don't let thermal degradation compromise your results. Contact KINTEK today to discover how our advanced heating solutions can optimize your lab's efficiency and product quality.

Visual Guide

References

- Wanjing Wang, Chunhuo Zhou. Selenium-Modified Biochar Synergistically Achieves the Safe Use of Selenium and the Inhibition of Heavy Metal Cadmium. DOI: 10.3390/molecules30020347

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does heat treatment affect the TPU encapsulation layer? Optimize Flexible Sensor Durability & Bonding

- How does a high-precision infrared temperature measurement system influence the sintering quality of Al2O3/TiC ceramics?

- What is the primary purpose of the 600°C annealing treatment? Optimize Silver-Coated Ceramic Performance

- Why is a vacuum desiccator essential for studying geopolymer porosity? Achieve Precise Material Characterization

- What is the purpose of treating EAF dust in a dryer? Ensure Precise Material Characterization & Data Integrity

- What is the role of a customized drying station with nitrogen purging? Optimize Polymer Blend Membrane Processing

- What is the temperature range of a lab furnace? Find Your Perfect Match

- What is the purpose of using an Argon Stream during activation? Enhance $CO_2$ Adsorption Efficiency