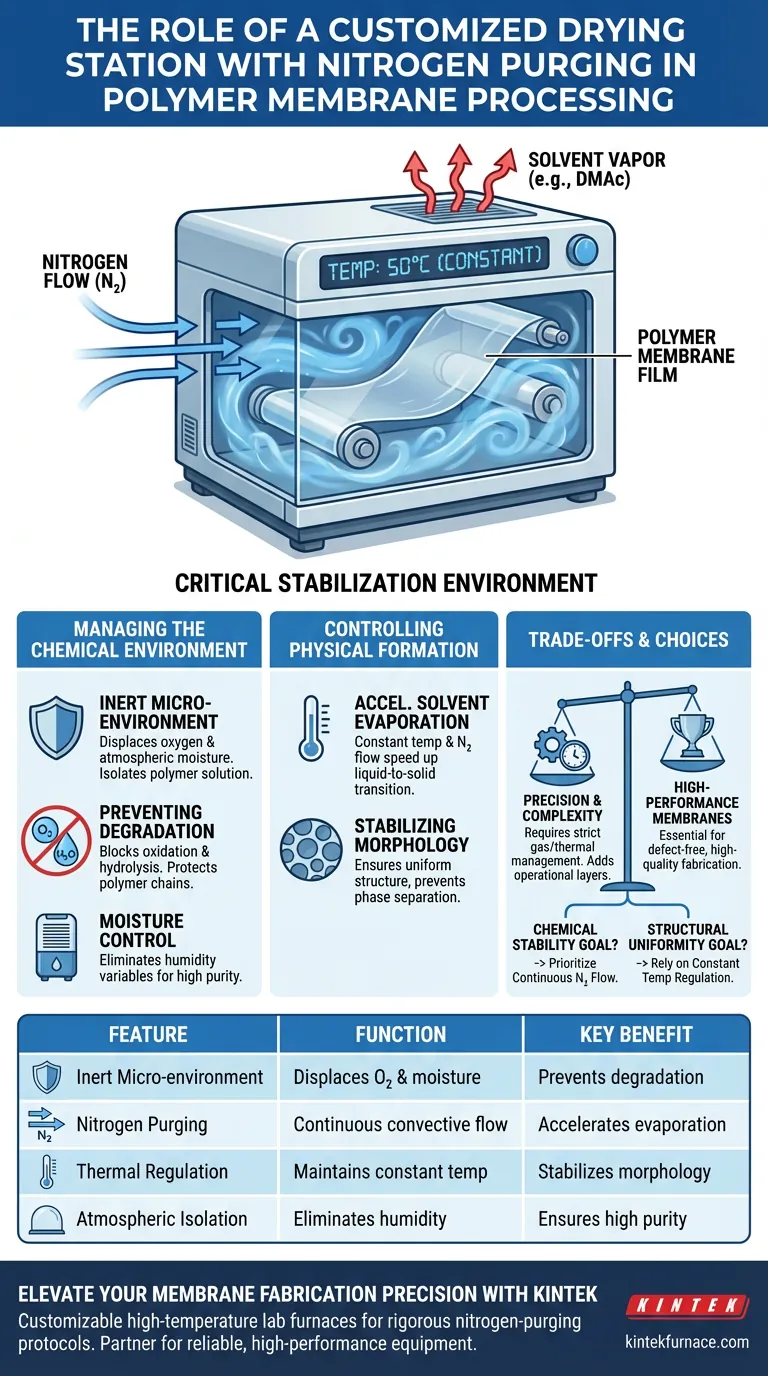

A customized drying station with nitrogen purging serves as a critical stabilization environment for processing polymer blend membranes. Its primary role is to establish a controlled inert micro-environment that accelerates the evaporation of solvents, such as DMAc, while simultaneously isolating the material from atmospheric variables. By maintaining a constant temperature and continuous gas flow, the station prevents chemical degradation and ensures the physical structure of the membrane develops correctly.

By eliminating atmospheric moisture and oxygen, nitrogen purging protects the polymer from oxidation and hydrolysis while locking in the desired morphology during the most vulnerable stage of film formation.

Managing the Chemical Environment

Creating an Inert Atmosphere

The most significant risk during membrane casting is exposure to reactive elements in the air. A continuous flow of nitrogen displaces the standard atmosphere surrounding the membrane.

This creates an inert micro-environment, effectively isolating the polymer solution.

Preventing Chemical Degradation

Many polymers are susceptible to degradation when exposed to air during the liquid-to-solid transition. Specifically, the nitrogen shield prevents oxidation, which can break down polymer chains.

It also prevents hydrolysis, a reaction with water vapor that can alter the chemical properties of the membrane.

Moisture Control

Atmospheric humidity is a major variable that can cause defects in membrane formation. The drying station ensures that the material is processed in a moisture-free zone.

This isolation is essential for maintaining the purity of the polymer blend during the initial casting phase.

Controlling Physical Formation

Accelerating Solvent Evaporation

The station is typically set to maintain a constant temperature, such as 50 °C. Combined with the convective flow of nitrogen, this accelerates the removal of solvents like DMAc.

Rapid, controlled evaporation is necessary to transition the membrane from a liquid state to a solid film efficiently.

Stabilizing Morphology

The speed and uniformity of solvent removal directly dictate the final structure of the membrane. An uncontrolled drying process can lead to phase separation or inconsistent pore structures.

Nitrogen purging helps stabilize the mixed morphology, ensuring the internal structure of the membrane forms as intended.

Understanding the Trade-offs

The Requirement for Precision

The effectiveness of this system relies entirely on consistency. A fluctuation in nitrogen flow or temperature disrupts the inert micro-environment immediately.

If the flow is interrupted, atmospheric moisture can re-enter the chamber, negating the protective benefits.

Equipment Complexity

Unlike open-air drying, this approach requires specialized equipment to maintain the micro-environment. You must manage gas supplies and thermal regulators strictly.

This adds a layer of operational complexity compared to passive drying methods, but is necessary for high-quality membrane fabrication.

Making the Right Choice for Your Goal

To maximize the effectiveness of your membrane processing, align your drying strategy with your specific material needs.

- If your primary focus is chemical stability: Prioritize the continuous nitrogen flow to prevent hydrolysis and oxidation in chemically sensitive polymer chains.

- If your primary focus is structural uniformity: Rely on the constant temperature regulation to control solvent evaporation rates and stabilize the membrane's internal morphology.

Precision in the drying phase is often the difference between a defective film and a high-performance membrane.

Summary Table:

| Feature | Function in Membrane Processing | Key Benefit |

|---|---|---|

| Inert Micro-environment | Displaces oxygen and atmospheric moisture | Prevents oxidation and hydrolysis degradation |

| Nitrogen Purging | Provides continuous convective gas flow | Accelerates solvent (e.g., DMAc) evaporation |

| Thermal Regulation | Maintains constant temperature (e.g., 50°C) | Stabilizes morphology and pore structure |

| Atmospheric Isolation | Eliminates humidity variables | Ensures high purity and structural uniformity |

Elevate Your Membrane Fabrication Precision

Achieving the perfect polymer morphology requires absolute control over your thermal and chemical environment. KINTEK provides industry-leading solutions backed by expert R&D and precision manufacturing.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temperature furnaces are fully customizable to meet the rigorous demands of your nitrogen-purging and drying protocols. Don't let atmospheric variables compromise your research—partner with KINTEK for reliable, high-performance equipment.

Contact KINTEK today to discuss your customized lab furnace needs

Visual Guide

References

- Chamaal Karunaweera, John P. Ferraris. Carbon–Carbon Composite Membranes Derived from Small-Molecule-Compatibilized Immiscible PBI/6FDA-DAM-DABA Polymer Blends. DOI: 10.3390/separations11040108

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is precision drying equipment necessary for porous mullite ceramic skeletons? Prevent Cracks & Ensure Integrity

- Process conditions for HEA cladding thermal experiments: Ensuring 800°C stability and 1680-hour endurance.

- What pre-treatment procedures are required for a Stainless Steel Reactor? Maximize Metal Hydride Reaction Success

- Why is a high-precision furnace critical for refractory castables? Ensure Structural Integrity & Mineral Stability

- Why is the ball milling step essential for NN-10ST ceramic synthesis? Unlock High-Purity Phase Formation

- Why is substrate preheating typically employed during the LPBF process? Minimize Stress & Prevent Cracks in 3D Printing

- What is the role of a laboratory oven in mushroom dehydration? Master Pre-Treatment for Precise Biochemical Analysis

- What is shrinkage in the context of high-temperature materials? Master Dimensional Control for Stronger Parts