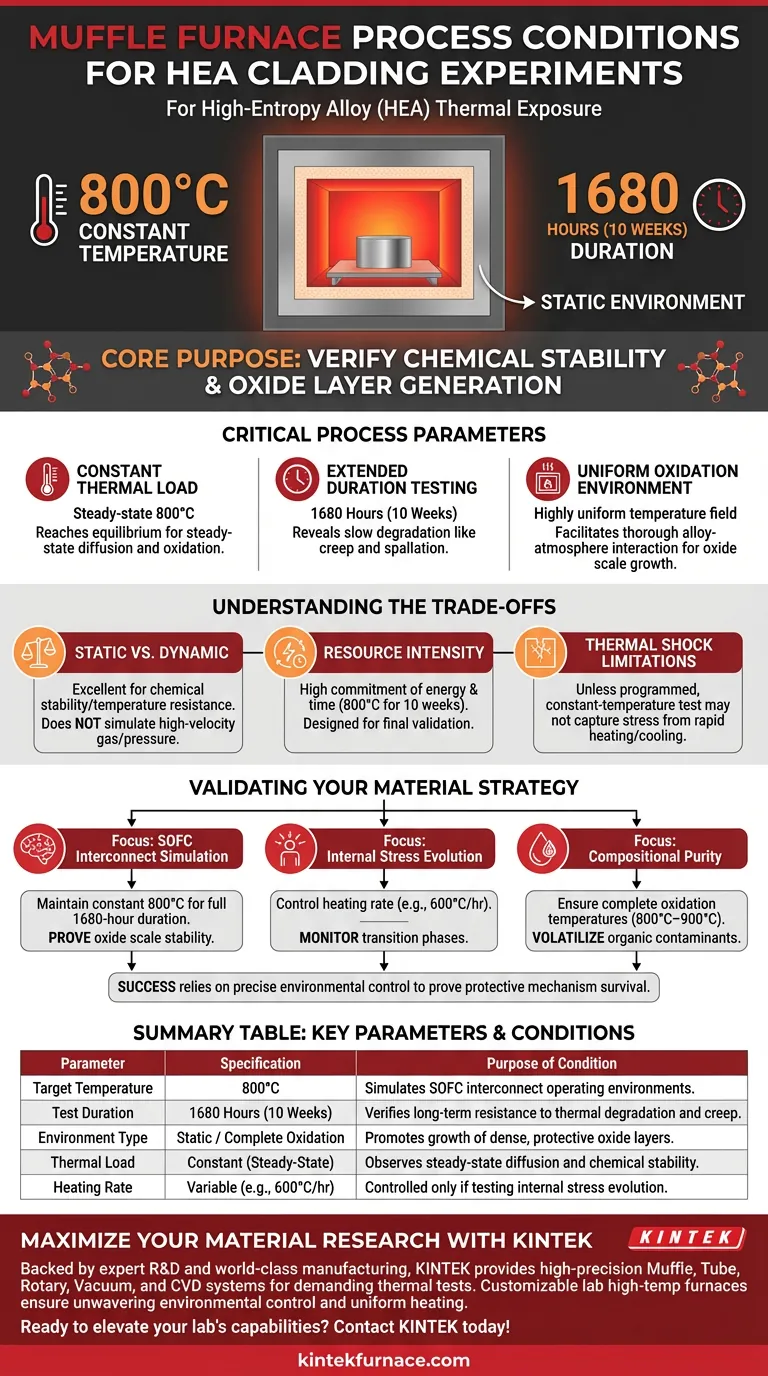

For high-entropy alloy (HEA) cladding experiments, a muffle furnace provides a static, constant temperature environment specifically maintained at 800°C for an extended duration of up to 1680 hours (approximately 10 weeks). These rigorous conditions are designed to simulate the extreme operational environment of Solid Oxide Fuel Cell (SOFC) interconnects, forcing the material to demonstrate its long-term resistance to thermal degradation.

The core purpose of this prolonged exposure is not merely heat resistance, but the verification of chemical stability. The muffle furnace environment tests whether the HEA coating can generate and sustain a dense, protective oxide layer that resists cracking and prevents thermal corrosion over time.

The Critical Process Parameters

Constant Thermal Load

The primary requirement for these experiments is maintaining a steady-state temperature of 800°C. Unlike cycling tests that fluctuate temperature, this process creates a continuous thermal load.

This constant exposure ensures that the material reaches equilibrium, allowing researchers to observe steady-state diffusion and oxidation processes that occur in real-world SOFC applications.

Extended Duration Testing

The validity of this experiment relies on the extreme duration of 1680 hours (10 weeks). Short-term tests often fail to reveal slow-acting degradation mechanisms like creep or oxide spallation.

By sustaining the environment for over two months, the process filters out transient successes and verifies if the FeCoNiMnCu coating maintains its structural integrity without suffering from volume-change induced cracking.

Uniform Oxidation Environment

While the primary reference focuses on the 800°C setpoint, the nature of a muffle furnace ensures a complete oxidation environment.

As noted in broader industrial applications, these furnaces provide a highly uniform temperature field that facilitates thorough interaction between the alloy surface and the surrounding atmosphere. This promotes the growth of the protective oxide scale, which is the primary mechanism the HEA uses to resist corrosion.

Understanding the Trade-offs

Static vs. Dynamic Simulation

A standard muffle furnace typically provides a static thermal environment. While excellent for testing chemical stability and temperature resistance, it does not simulate the high-velocity gas flows or pressure differentials found in some active engine or fuel cell environments.

Resource Intensity

Running a furnace at 800°C for 10 weeks represents a significant consumption of energy and time. This is a high-commitment testing protocol designed for final validation rather than rapid prototyping or initial material screening.

Thermal Shock Limitations

Unless specifically programmed with a ramp rate (e.g., the 600°C/hour rate used in other stress evolution tests), a standard constant-temperature test may not capture the mechanical stresses caused by rapid heating or cooling (thermal shock). It is strictly a test of endurance at operating temperature.

Validating Your Material Strategy

To ensure your experimental setup yields relevant data, align your furnace parameters with your specific testing goals:

- If your primary focus is SOFC Interconnect Simulation: Maintain a strictly constant 800°C for the full 1680-hour duration to prove long-term oxide scale stability.

- If your primary focus is Internal Stress Evolution: You must control the heating rate (e.g., 600°C per hour) to monitor how the material handles the transition phases before reaching the target temperature.

- If your primary focus is Compositional Purity: Ensure the furnace reaches complete oxidation temperatures (800°C–900°C) to fully volatilize any organic contaminants, similar to biomass ashing protocols.

Success in these experiments relies on precise, unwavering environmental control to prove that the alloy's protective mechanisms can survive indefinite operation.

Summary Table:

| Parameter | Specification | Purpose of Condition |

|---|---|---|

| Target Temperature | 800°C | Simulates SOFC interconnect operating environments. |

| Test Duration | 1680 Hours (10 Weeks) | Verifies long-term resistance to thermal degradation and creep. |

| Environment Type | Static / Complete Oxidation | Promotes growth of dense, protective oxide layers. |

| Thermal Load | Constant (Steady-State) | Observes steady-state diffusion and chemical stability. |

| Heating Rate | Variable (e.g., 600°C/hr) | Controlled only if testing internal stress evolution. |

Maximize Your Material Research with KINTEK

Backed by expert R&D and world-class manufacturing, KINTEK provides high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding thermal exposure tests. Whether you are conducting 10-week HEA cladding endurance runs at 800°C or complex stress evolution studies, our customizable lab high-temp furnaces ensure unwavering environmental control and uniform heating for reliable data.

Ready to elevate your lab’s capabilities? Contact KINTEK today to find the perfect thermal solution for your unique research needs!

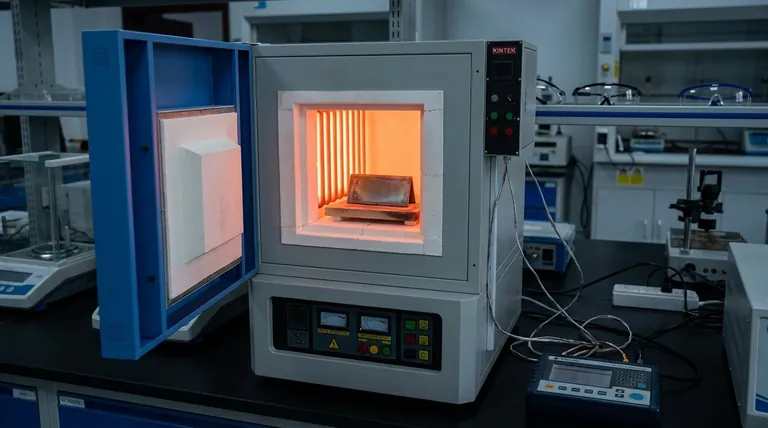

Visual Guide

References

- Shubham Sharma, Emad A. A. Ismail. Investigation of surface hardness, thermostability, tribo-corrosion, and microstructural morphological properties of microwave-synthesized high entropy alloy FeCoNiMnCu coating claddings on steel. DOI: 10.1038/s41598-024-55331-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the technical advantages of using high-purity hydrogen as a protective atmosphere? Boost Heat Treatment Speed

- Why is an incubator required for VP-FSCM? Master Curing Controls for Superior Soil Solidification Results

- Why is precision constant temperature control required during the hardening stage of geopolymer mortar? Guide to Success

- Why must MgO for MKPC be produced at 1600°C? Mastering Chemical Kinetics for High-Performance Modification Slurries

- How do heating rate and holding temperature influence Zr2.5Nb nitride growth? Optimize Your ZrN Layer Thickness

- Why is thermal growth oxidation preferred for SiO2 gate dielectrics? Superior Quality for a-IGZO TFTs

- Why is 10^-6 mbar pressure required for CZTS PLD? Ensure Pure, High-Efficiency Thin Film Deposition

- What is the necessity of calcining silica aerogels at 300°C? Unlock Peak Insulation with Precise Calcination