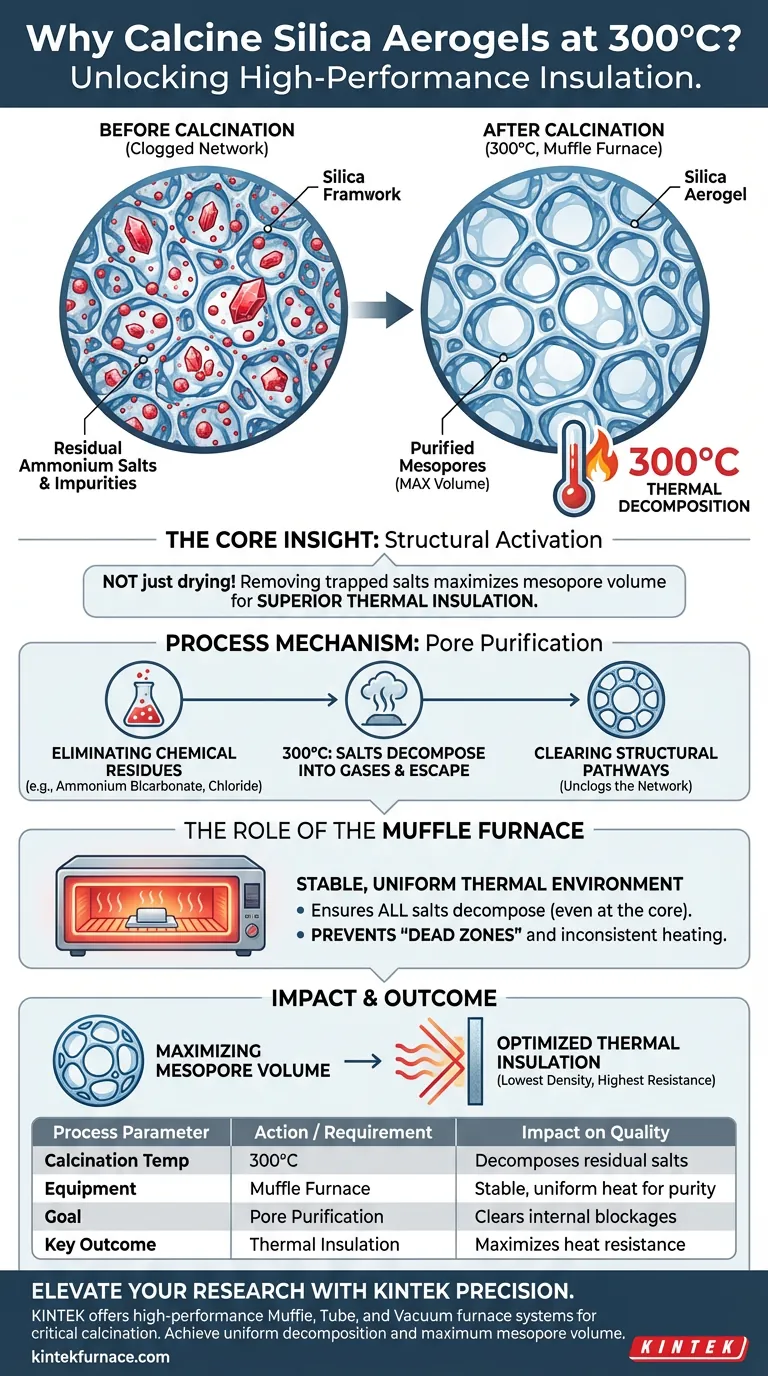

The primary necessity of calcining silica aerogels at 300°C is the complete removal of chemical impurities. This process utilizes the stable environment of a muffle furnace to decompose residual ammonium salts trapped within the material. By eliminating these byproducts, the process clears the aerogel's internal structure, which is a prerequisite for achieving its high-performance characteristics.

Core Insight: Calcination is not merely a drying step; it is a structural activation process. By removing undecomposed salts, you maximize mesopore volume, which is the decisive factor in determining the final thermal insulation capability of the aerogel.

The Mechanism of Pore Purification

Eliminating Chemical Residues

During the synthesis of silica aerogels, chemical byproducts inevitably remain within the matrix. Specifically, residual undecomposed ammonium salts, such as ammonium bicarbonate and ammonium chloride, become trapped.

Why 300°C is Critical

Subjecting the material to 300°C triggers the thermal decomposition of these specific salts. This temperature is sufficient to break down the solid residues into gases, allowing them to escape the structure without damaging the silica network.

Clearing the Structural Pathways

The presence of these salts acts as a blockage within the aerogel's intricate pore network. Calcination effectively "unclogs" the material, transforming a filled structure into an open, porous framework.

Impact on Material Performance

Maximizing Mesopore Volume

The direct physical result of removing these ammonium salts is a significant increase in mesopore volume. As the solid salts vacate the pores, they leave behind valuable empty space that defines the aerogel's low density.

Optimizing Thermal Insulation

The thermal insulation performance of an aerogel is directly tied to its porosity and pore volume. By clearing the pores of solid conductive matter, calcination ensures the material achieves its maximum potential for resisting heat transfer.

The Role of the Muffle Furnace

Ensuring Thermal Stability

The primary reference highlights that a high-performance muffle furnace is required to provide a "stable and uniform thermal environment." Standard ovens may fluctuate, leading to uneven heating.

Guiding Uniform Decomposition

Uniformity is critical because the salts are distributed throughout the aerogel's entire volume. A muffle furnace ensures that the center of the sample reaches the same 300°C temperature as the surface, guaranteeing that no pockets of undecomposed salts remain.

Understanding the Process Risks

The Consequence of Incomplete Calcination

If the temperature is inconsistent or the heat source is unstable, the removal of ammonium salts will be partial. This results in "dead zones" within the aerogel where pores remain clogged, reducing the overall mesopore volume.

Equipment Limitations

Using equipment that cannot maintain strict thermal uniformity compromises the final product. Even a slight failure to remove residual salts will measurably degrade the thermal insulation properties, rendering the aerogel less effective for its intended application.

Making the Right Choice for Your Goal

To ensure you are manufacturing silica aerogels that meet high-performance standards, focus on the following parameters:

- If your primary focus is Maximum Insulation: Prioritize complete salt decomposition to ensure the pore network is entirely unobstructed.

- If your primary focus is Process Consistency: Utilize a high-quality muffle furnace to guarantee the thermal uniformity required for total pore clearance.

The difference between a mediocre aerogel and a high-performance insulator often lies entirely in the thoroughness of this final calcination step.

Summary Table:

| Process Parameter | Action / Requirement | Impact on Aerogel Quality |

|---|---|---|

| Calcination Temp | 300°C | Decomposes residual ammonium salts into gases |

| Equipment Type | Muffle Furnace | Provides the stable, uniform heat required for purity |

| Structural Goal | Pore Purification | Clears internal blockages to maximize mesopore volume |

| Key Outcome | Thermal Insulation | Minimizes heat transfer by ensuring an open porous framework |

Elevate Your Aerogel Research with KINTEK Precision

Don't let inconsistent heating compromise your material's thermal performance. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, and Vacuum furnace systems specifically designed to provide the thermal stability required for critical calcination processes. Whether you need a standard setup or a customizable solution for unique lab requirements, our equipment ensures uniform decomposition and maximum mesopore volume for your silica aerogels.

Ready to achieve superior insulation results? Contact our technical experts today to find the perfect furnace for your application!

Visual Guide

References

- Jinjing Guo, Baohua Guo. Enhancing Mesopore Volume and Thermal Insulation of Silica Aerogel via Ambient Pressure Drying-Assisted Foaming Method. DOI: 10.3390/ma17112641

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary purpose of continuously introducing high-purity argon gas? 4 Critical Roles in Solar Pyrolysis

- What are the advantages of using a stainless steel fixed bed reactor for biochar pyrolysis? Unlock Precise Lab Results

- Why must Ru/GNK catalysts undergo vacuum drying? Ensure Peak Performance with Safe Desorption

- Why is charcoal used as a susceptor material during the microwave cladding of FeCoNiMnCu? Unlock efficient heating.

- What are the two methods of temperature control of resistance furnace? Optimize for Precision or Cost

- How does the pulling and rotation control system of a Czochralski growth furnace affect crystal quality?

- What role does a pyrolysis device play in the synthesis of porous carbon for supercapacitors? Essential Thermal Secrets

- What are the main advantages of crucible furnaces? Unmatched Flexibility for Small-Scale Melting