A pyrolysis device serves as the central thermal reactor in the synthesis of supercapacitor materials, specifically designed to convert biomass precursors into porous carbon. It maintains a strictly controlled high-temperature environment that facilitates thermal decomposition, transforming raw organic matter into a stable, conductive carbon framework.

By precisely managing heat and atmosphere, the pyrolysis device drives the structural evolution of biomass into high-surface-area carbon, which is the essential prerequisite for high-performance energy storage.

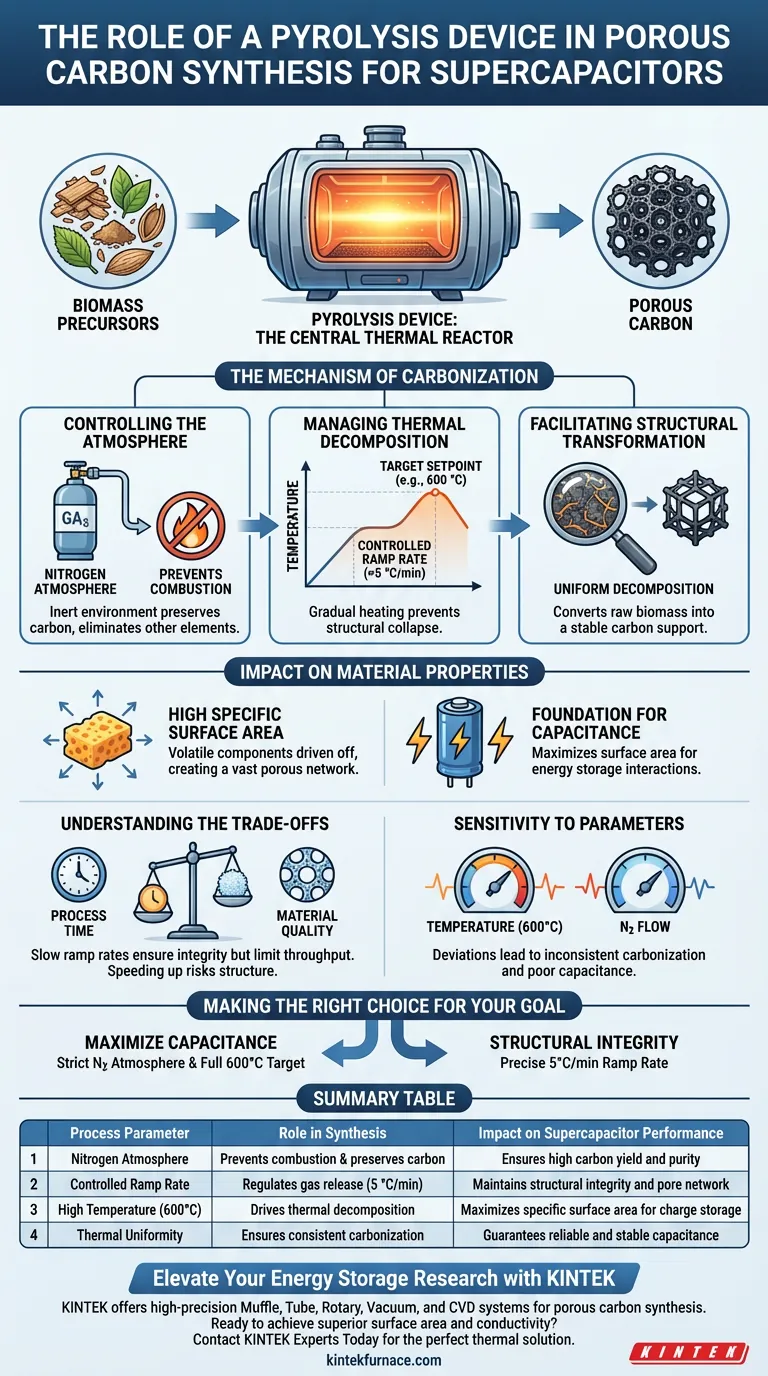

The Mechanism of Carbonization

To understand the role of the pyrolysis device, one must look at how it manipulates the physical environment to alter material chemistry.

Controlling the Atmosphere

The device operates under a specific nitrogen atmosphere. This inert environment is critical because it prevents the biomass from combusting (burning) as it would in oxygen.

Instead of burning to ash, the organic material undergoes carbonization. This preserves the carbon structure while eliminating other elements.

Managing Thermal Decomposition

The device does not simply blast the material with heat; it applies a controlled ramp rate, typically around 5 °C/min.

This gradual increase prevents structural collapse caused by rapid gas release. The temperature is raised steadily until it reaches a target setpoint, such as 600 °C.

Facilitating Structural Transformation

At these high temperatures, thermal decomposition occurs. The device ensures this process happens uniformly throughout the precursor material.

This decomposition is what physically converts the raw biomass into a carbon-based support material.

Impact on Material Properties

The ultimate goal of using a pyrolysis device is not just carbonization, but the enhancement of specific physical properties required for supercapacitors.

Creating High Specific Surface Area

The primary output of this thermal process is a material with a high specific surface area. As volatile components are driven off by the heat, a porous network remains.

This porosity is the defining feature that allows the material to function effectively in energy storage applications.

Foundation for Capacitance

The porous carbon produced acts as the foundation for capacitance performance.

Supercapacitors rely on surface interactions to store energy. Therefore, the device's ability to maximize surface area directly correlates to the final electrical performance of the device.

Understanding the Trade-offs

While the pyrolysis device is essential, the process involves inherent constraints that must be managed.

Process Time vs. Material Quality

The requirement for a specific, slow ramp rate (e.g., 5 °C/min) creates a bottleneck in production speed.

Accelerating this heating process to save time risks compromising the structural integrity of the pores. You trade throughput for the high specific surface area necessary for performance.

Sensitivity to Parameters

The synthesis is highly sensitive to the device's accuracy.

Deviations from the target temperature of 600 °C or fluctuations in the nitrogen flow can result in inconsistent carbonization, leading to poor capacitance.

Making the Right Choice for Your Goal

When employing a pyrolysis device for supercapacitor research or production, align your parameters with your specific performance targets.

- If your primary focus is Maximizing Capacitance: Ensure the device maintains a strict nitrogen atmosphere and reaches the full 600 °C target to guarantee maximum surface area development.

- If your primary focus is Structural Integrity: Prioritize the precision of the ramp rate (5 °C/min) to prevent thermal shock and ensure uniform pore formation.

The pyrolysis device is not merely a furnace; it is a precision instrument that dictates the ultimate energy storage capability of your carbon material.

Summary Table:

| Process Parameter | Role in Synthesis | Impact on Supercapacitor Performance |

|---|---|---|

| Nitrogen Atmosphere | Prevents combustion & preserves carbon | Ensures high carbon yield and purity |

| Controlled Ramp Rate | Regulates gas release (5 °C/min) | Maintains structural integrity and pore network |

| High Temperature (600°C) | Drives thermal decomposition | Maximizes specific surface area for charge storage |

| Thermal Uniformity | Ensures consistent carbonization | Guarantees reliable and stable capacitance |

Elevate Your Energy Storage Research with KINTEK

Precise carbonization is the backbone of high-performance supercapacitors. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of porous carbon synthesis. Our customizable lab high-temp furnaces provide the atmosphere control and ramp-rate accuracy your unique biomass precursors require.

Ready to achieve superior surface area and conductivity?

Contact KINTEK Experts Today to find the perfect thermal solution for your lab.

Visual Guide

References

- Serkan Demirel, Mehmet Hakkı Alma. High capacitive pt and NiOx loaded supercapacitors with commercial and green synthesized carbon-based materials. DOI: 10.1007/s10854-023-11885-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why is a constant temperature blast drying oven necessary for biomass carbon impregnation? Optimize Material Structure

- How do high-temp furnace processes affect carbon nanofiber micro-morphology? Master Precise Structural Control

- How do high-precision industrial furnaces contribute to thermal stability research in cement composites?

- How does an oil circulation heating and cooling system affect HPDC? Optimize Your Die Casting Thermal Control

- How is the pore structure of EN-LCNF characterized? Advanced BET and DFT Analysis of Carbon Nanosheets

- Why is vacuum degassing necessary for ZIF-8 impregnation? Achieve Uniform Macroporous Material Synthesis

- How does the Flash Heating (FH) process impact the growth of REBCO films? Master Rapid Thermal Ramp Requirements

- What is the purpose of using an Argon Stream during activation? Enhance $CO_2$ Adsorption Efficiency